Preparation method and application of phosphorus-nitrogen-carbon-containing aggregate and intumescent flame retardant

An intumescent flame retardant and polymerized technology, which is applied in the field of preparation of phosphorus-nitrogen-carbon polymeric intumescent flame retardants, can solve the problems of high acidity, high solubility, poor compatibility of polymer matrix, etc. The preparation method is environmentally friendly, the raw materials are environmentally friendly and non-toxic, and the preparation method is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a phosphorus-nitrogen-carbon polymerization type intumescent flame retardant, the steps are:

[0031]Add 0.08mol melamine to the reaction vessel equipped with magnetic stirring, then add 160ml ethanol, stir and add 0.015mol phytic acid at 20°C, keep the system temperature constant after adding and continue stirring for 50 minutes, then pour the reaction solution into poly In a tetrafluoro reactor, react at a temperature of 120°C for 24 hours. After the reaction, pour out the reaction product, wash it with ethanol and then water several times until the pH is about 7 and no longer change, filter it with suction, and then dry it at a temperature of 60°C and a pressure of -0.08MPa for 10 hours to obtain a white solid product , that is, phosphorus-nitrogen-carbon polymerized intumescent flame retardant, referred to as PAMA1.

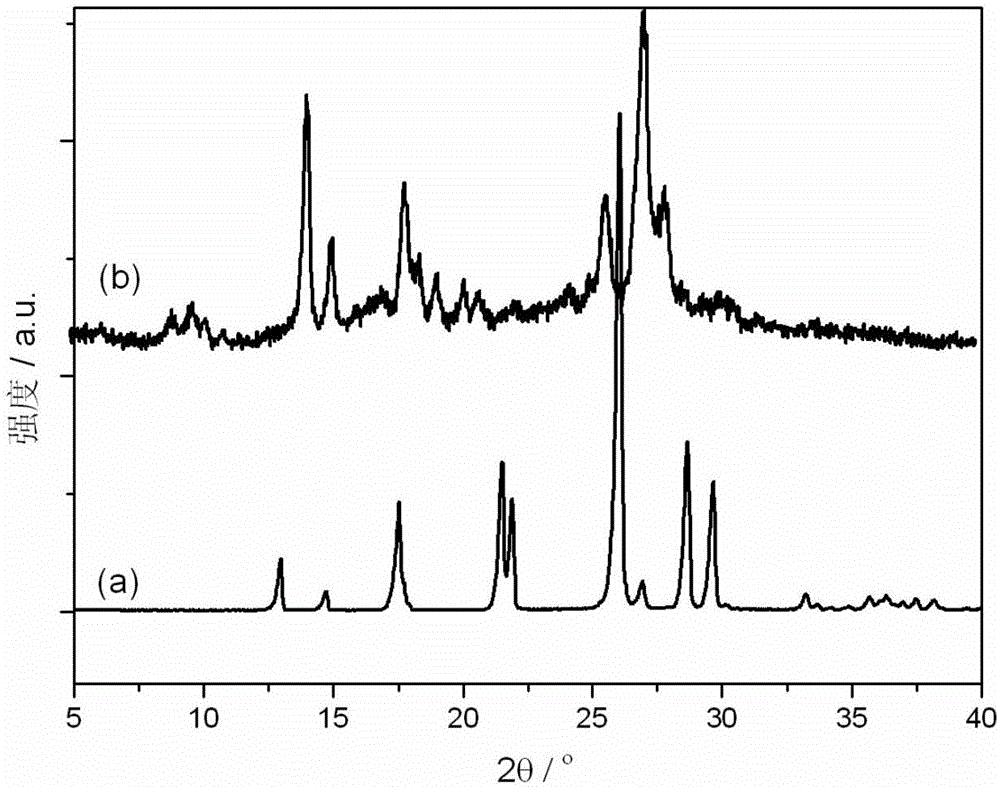

[0032] The X-ray diffraction pattern of this intumescent flame retardant (as figure 1 (b)) shows: the characteristic peak of...

Embodiment 2

[0034] A preparation method of phosphorus-nitrogen-carbon polymerized intumescent flame retardant, the steps are: add 0.09mol melamine to a reaction vessel equipped with magnetic stirring, then add 450ml of distilled water, stir and add 0.03mol After adding phytic acid, keep the temperature of the system constant and continue to stir for 40 minutes, then pour the reaction solution into a polytetrafluoro reactor, and react at a temperature of 90°C for 56 hours. After the reaction, the reaction product was poured out, washed with ethanol and then water for several times until the pH was about 7 and no longer changed, filtered with suction, and then dried at a temperature of 70°C and a pressure of -0.1MPa for 24 hours to obtain a white solid The product is the phosphorus-nitrogen-carbon polymerized intumescent flame retardant, referred to as PAMA2.

Embodiment 3

[0036] A preparation method of a phosphorus-nitrogen-carbon polymerized intumescent flame retardant, the steps are: add 0.15mol melamine to a reaction vessel equipped with magnetic stirring, then add 450ml of acetone, stir and add 0.01mol at 25°C After adding phytic acid, keep the temperature of the system constant and continue to stir for 20 minutes, then pour the reaction solution into a polytetrafluoro reactor, and react at a temperature of 70°C for 36 hours. After the reaction, pour out the reaction product, wash it with ethanol and then water for several times until the pH is about 7 and no longer change, filter it with suction, and then dry it for 8 hours at a temperature of 40°C and a pressure of -0.06MPa to obtain a white solid product , that is, phosphorus-nitrogen-carbon polymerized intumescent flame retardant, referred to as PAMA3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com