Anti-static and high-flame-retardant ABS (acrylonitrile butadiene styrene) composite material and preparation method thereof

A composite material and high flame-retardant technology, which is applied in the field of preparation of antistatic high flame-retardant ABS composite materials, can solve the problems of poor flame retardancy and antistatic performance, and achieve good physical strength and smoke absorption. , the effect of rich specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

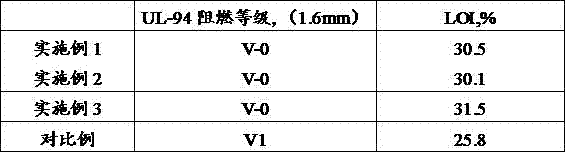

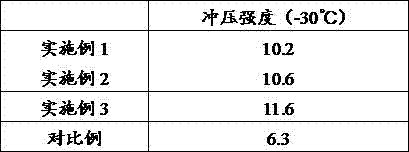

Embodiment 1

[0031] Antistatic high flame retardant ABS composite material, the antistatic high flame retardant ABS composite material is processed from the following raw materials by weight: 60 parts of ABS resin, 40 parts of PC resin, 5 parts of EPDM resin, 6 parts of antioxidant, nano 5 parts of silver, 8 parts of composite flame retardant, 5 parts of low-temperature resistant plasticizer, and 5 parts of antistatic agent. The composite flame retardant is ammonium polyphosphate-diatomite / magnetic ordered mesoporous prepared by in-situ polymerization Nickel ferrite composite flame retardant, the preparation method of the composite flame retardant is as follows: pour 85% concentrated phosphoric acid into the reactor, heat and stir, and add an appropriate amount of urea when the temperature rises to 60°C, and when the temperature rises to 125°C, add Appropriate amount of diatomaceous earth and magnetically ordered mesoporous nickel ferrite powder, stirred for 10 minutes, then solidified the ...

Embodiment 2

[0034] Antistatic high flame retardant ABS composite material, the antistatic high flame retardant ABS composite material is processed from the following raw materials in parts by weight: 80 parts of ABS resin, 60 parts of PC resin, 10 parts of EPDM resin, 10 parts of antioxidant, nano 8 parts of silver, 12 parts of composite flame retardant, 8 parts of low-temperature resistant plasticizer, and 8 parts of antistatic agent. The composite flame retardant is ammonium polyphosphate-diatomite / magnetic ordered mesoporous prepared by in-situ polymerization Nickel ferrite composite flame retardant, the preparation method of the composite flame retardant is as follows: pour 85% concentrated phosphoric acid into the reactor, heat and stir, and add an appropriate amount of urea when the temperature rises to 80°C, and when the temperature rises to 120°C, add Appropriate amount of diatomaceous earth and magnetically ordered mesoporous nickel ferrite powder, stirred for 20 minutes, then cur...

Embodiment 3

[0037]Antistatic high flame retardant ABS composite material, the antistatic high flame retardant ABS composite material is processed from the following raw materials by weight: 70 parts of ABS resin, 50 parts of PC resin, 6 parts of EPDM resin, 8 parts of antioxidant, nano 6 parts of silver, 10 parts of composite flame retardant, 6 parts of low-temperature resistant plasticizer, 6 parts of antistatic agent, the composite flame retardant is ammonium polyphosphate-diatomite / magnetic ordered mesoporous prepared by in-situ polymerization Nickel ferrite composite flame retardant, the preparation method of the composite flame retardant is as follows: pour 85% concentrated phosphoric acid into the reactor, heat and stir, and add an appropriate amount of urea when the temperature rises to 70°C, and when the temperature rises to 122°C, add Appropriate amount of diatomaceous earth and magnetically ordered mesoporous nickel ferrite powder, stirred for 15 minutes, then cured the product a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com