A kind of coated flame retardant, its preparation method and application, and molding composition composed of it

A technology for molding compositions and flame retardants, applied in the fields of molding compositions and coated flame retardants, can solve problems such as uneven dispersion of compound flame retardants, optimize surface properties, and solve migration and precipitation , Improve the effect of flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

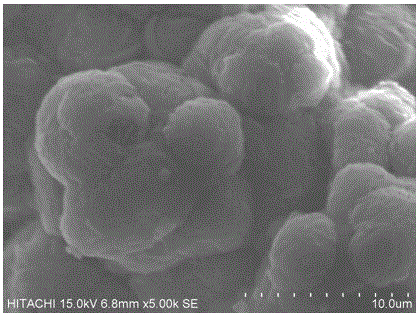

[0119] A coated flame retardant, containing a core material of melamine with a particle size D(50) of 20.12 μm, and a coating layer of diethyl aluminum phosphinate on the outer surface of the core material, wherein diethyl phosphinate The mass ratio of aluminum-based phosphinate to melamine is 100:1; the particle size D (50) of the coated flame retardant is 31.33 μm; the moisture content is 0.15%; the bulk density is 561 g / L.

[0120] The preparation method of described coating type flame retardant comprises the steps:

[0121] a) Add 10g of melamine into 990g of water to make a melamine suspension;

[0122] b) According to the mass ratio of the melamine core material and the aluminum diethylphosphinate coating layer of 1:100, add 3692g of 30% sodium diethylphosphinate aqueous solution into the melamine suspension, and add 1707g 50% aluminum sulfate aqueous solution, reaction is completed at 70 ℃;

[0123] c) The coating reaction product was filtered, washed, and dried at 20...

Embodiment 2

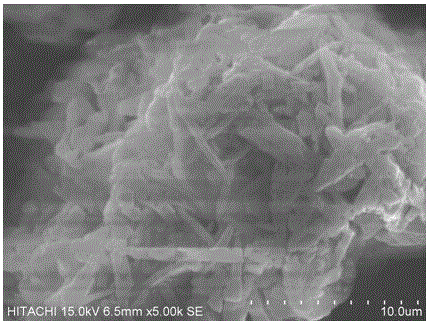

[0127] A coated flame retardant, containing a core material of melamine polyphosphate with a particle size D(50) of 10.35 μm, and a coating layer of aluminum diethylphosphinate on the outer surface of the core material, wherein , the mass ratio of aluminum diethylphosphinate to melamine polyphosphate is 100:60; the particle size D (50) of the coated flame retardant is 30.12 μm; the moisture content is 0.43%; the bulk density is 650g / L.

[0128] The preparation method of described coating type flame retardant comprises the steps:

[0129] a) Take 100g of melamine polyphosphate and add it into 100g of water to make a suspension of melamine polyphosphate;

[0130] b) According to the mass ratio of the melamine polyphosphate core material and the aluminum diethylphosphinate coating layer of 60:100, add 1846g of 10% sodium diethylphosphinate aqueous solution into the melamine polyphosphate suspension, Add 771g 20% aluminum sulfate aqueous solution in above-mentioned mixed solu...

Embodiment 3

[0135] A coated flame retardant, containing melamine with a particle size D (50) of 20.12 μm and a core material of a mixture of melamine polyphosphate with a D (50) of 10.35 μm, and the outer surface of the core material is coated with diethylene glycol The coating layer of aluminum-based phosphinate, wherein the mass ratio of melamine, melamine-polyphosphate mixture and aluminum diethylphosphinate coating layer is 6.7:33.3:100; the particle size of the coating-type flame retardant The diameter D (50) is 42.64μm; the moisture content is 0.32%; the bulk density is 612g / L.

[0136] The preparation method of described coating type flame retardant comprises the steps:

[0137] a) Add 16.7g of melamine and 83.3g of melamine polyphosphate into 400g of water to form a suspension of a mixture of melamine and melamine polyphosphate;

[0138] b) According to the mass ratio of melamine, melamine polyphosphate mixture core material and aluminum diethylphosphinate coating layer is 6.7:33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com