EPS flame-retardant masterbatch and preparation method thereof

A technology of flame retardant masterbatch and masterbatch, which is applied in the field of flame retardant masterbatch production, which can solve problems such as difficulty in mixing evenly, polluting the surrounding environment, and easy to raise dust, etc., to achieve increased gloss and processing performance, good flame retardant effect, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

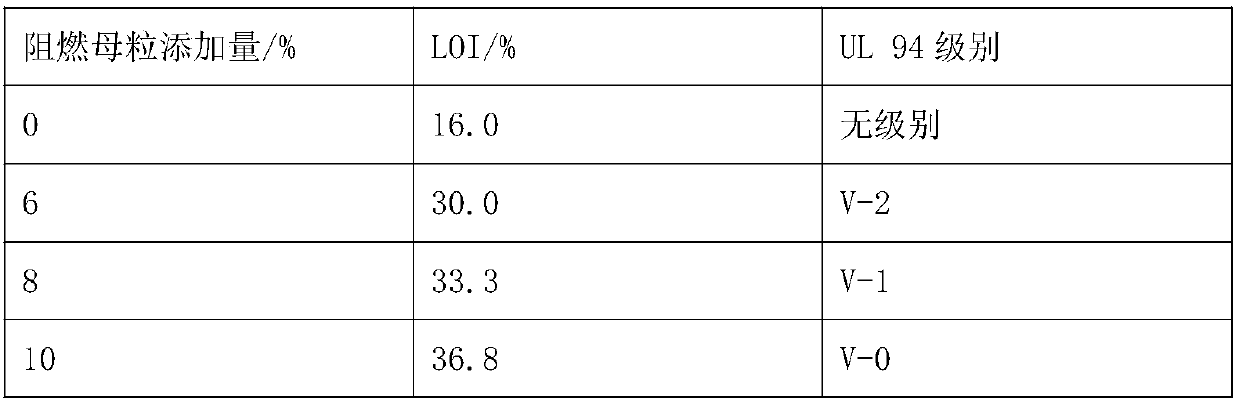

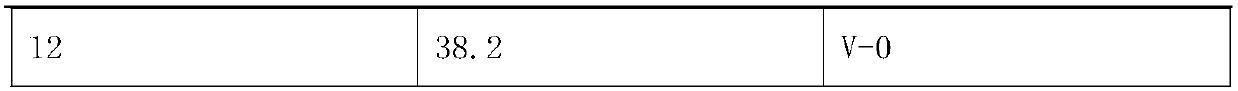

Examples

Embodiment 1

[0020] An EPS flame retardant masterbatch, prepared from the following raw materials in parts by weight: 60 parts of polystyrene, 30 parts of brominated SBS, 20 parts of methyl octabromoether, 5 parts of graphite masterbatch, and 3 parts of barium stearate , 3 parts of aluminum dioxide, 2 parts of polyethylene wax, 3 parts of talcum powder, 10104 parts of antioxidant.

[0021] The graphite masterbatch is 600 mesh natural flake graphite.

[0022] The present invention also provides a preparation method of EPS flame retardant masterbatch, comprising steps:

[0023] (1) taking various raw materials according to the stated parts by weight;

[0024] (2) Add the various raw materials taken by weighing into the high-efficiency mixer and fully mix;

[0025] (3) Add the mixed material into a twin-screw extruder, and melt and extrude to obtain a flame-retardant masterbatch.

[0026] The melt extrusion temperature in the step (3) is 220° C., the screw speed of the twin-screw extruder ...

Embodiment 2

[0028] An EPS flame retardant masterbatch, prepared from the following raw materials in parts by weight: 80 parts of polystyrene, 40 parts of brominated SBS, 30 parts of methyl octabromoether, 10 parts of graphite masterbatch, and 5 parts of barium stearate , 8 parts of aluminum dioxide, 6 parts of polyethylene wax, 8 parts of talcum powder, and 10109 parts of antioxidant.

[0029] The graphite masterbatch is 700 mesh natural flake graphite.

[0030] The present invention also provides a preparation method of EPS flame retardant masterbatch, comprising steps:

[0031] (1) taking various raw materials according to the stated parts by weight;

[0032] (2) Add the various raw materials taken by weighing into the high-efficiency mixer and fully mix;

[0033] (3) Add the mixed material into a twin-screw extruder, and melt and extrude to obtain a flame-retardant masterbatch.

[0034] The melt extrusion temperature in the step (3) is 220° C., the screw speed of the twin-screw extr...

Embodiment 3

[0036] An EPS flame retardant masterbatch prepared from the following raw materials in parts by weight: 70 parts of polystyrene, 34 parts of brominated SBS, 26 parts of methyl octabromoether, 7.5 parts of graphite masterbatch, and 4 parts of barium stearate , 6 parts of aluminum dioxide, 4.2 parts of polyethylene wax, 5 parts of talcum powder, and 10106 parts of antioxidant.

[0037] The graphite masterbatch is 800 mesh natural flake graphite.

[0038] The present invention also provides a preparation method of EPS flame retardant masterbatch, comprising steps:

[0039] (1) taking various raw materials according to the stated parts by weight;

[0040] (2) Add the various raw materials taken by weighing into the high-efficiency mixer and fully mix;

[0041] (3) Add the mixed material into a twin-screw extruder, and melt and extrude to obtain a flame-retardant masterbatch.

[0042] The melt extrusion temperature in the step (3) is 220° C., the screw speed of the twin-screw ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com