Colored antibacterial polypropylene film and preparation method thereof

A technology of antibacterial polypropylene and colored polypropylene, which is applied in the field of colored antibacterial polypropylene film and its preparation, and can solve the problems of poor compatibility between colorants and polymers, easy loss of colorants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

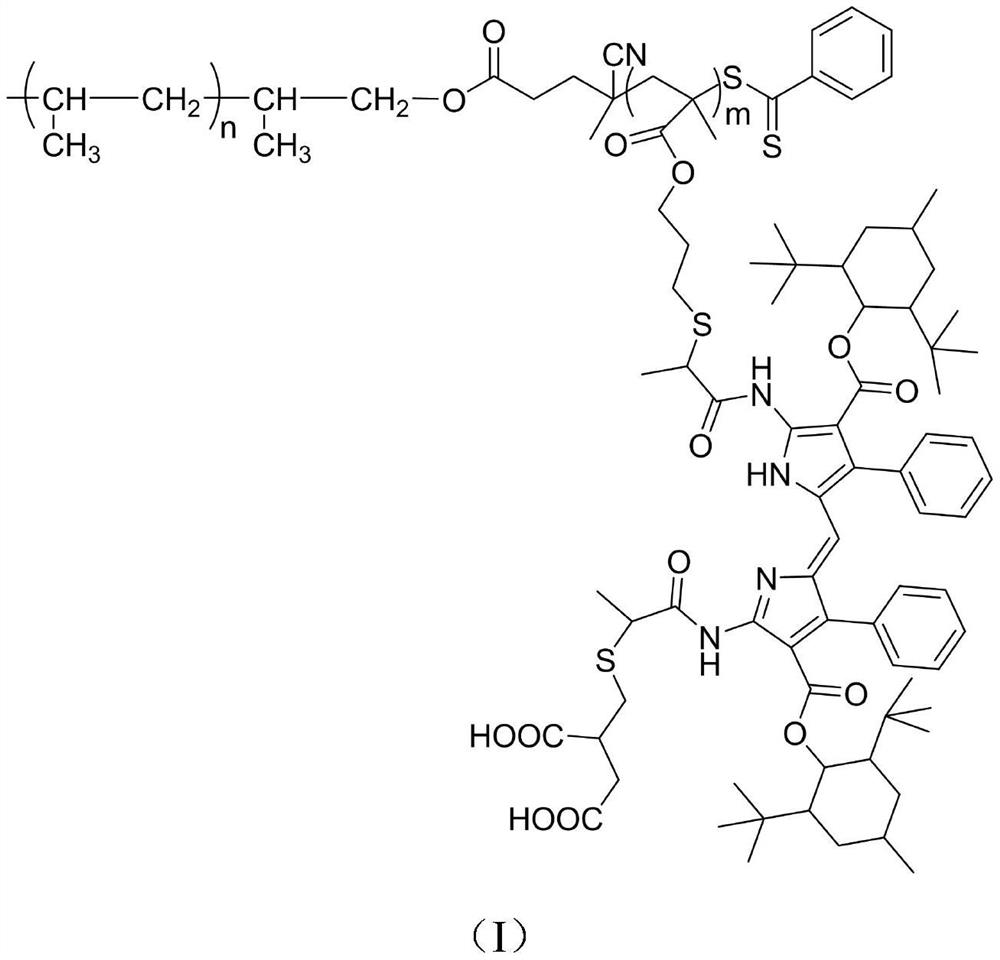

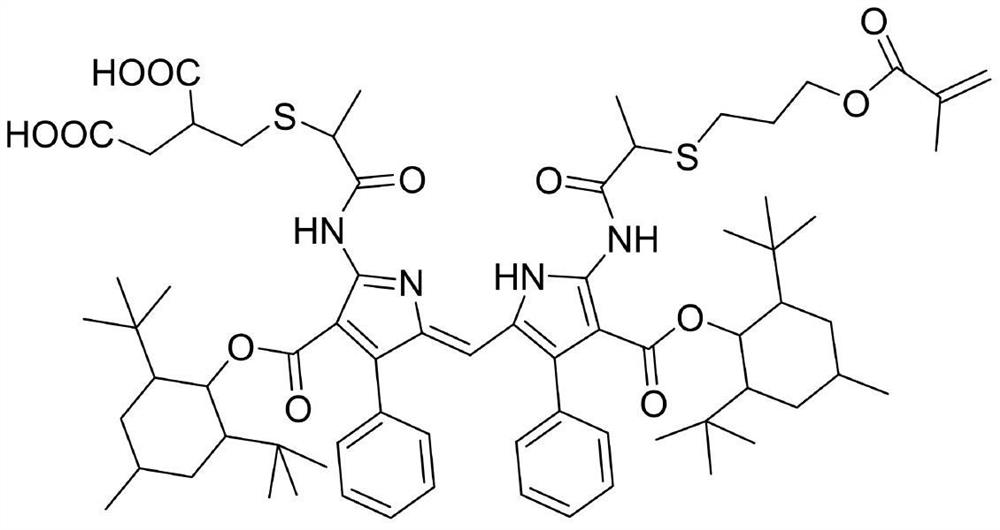

[0028] Add 4-cyano-4-(thiobenzoyl)valeric acid (5.0mmol) into a 50ml branch bottle equipped with a stirring bar, add 20ml of anhydrous tetrahydrofuran THF with a syringe, and slowly dropwise add the chlorinated Sulfoxide SOCl 2 (10.0mmol), the temperature of the oil bath was raised to 75°C, and refluxed for 1.5h. After the reaction was completed, the SOCl was distilled off under reduced pressure. 2 And THF, a yellow oily product was obtained, which was dissolved with an appropriate amount of toluene solution.

[0029] Add single-end hydroxyl polypropylene PP-OH (1.0mmol) into a 100mL branch bottle equipped with a stirring bar, pump nitrogen three times, and then 2 Under the atmosphere, add 30ml of anhydrous toluene, under constant stirring, slowly heat the temperature of the oil bath to 70°C, after the polymer is completely melted, add 1.5ml of pyridine, after 40min, slowly add the above yellow solution dissolved in toluene The oily product was reacted at 80°C for 2.5h, the ...

Embodiment 2

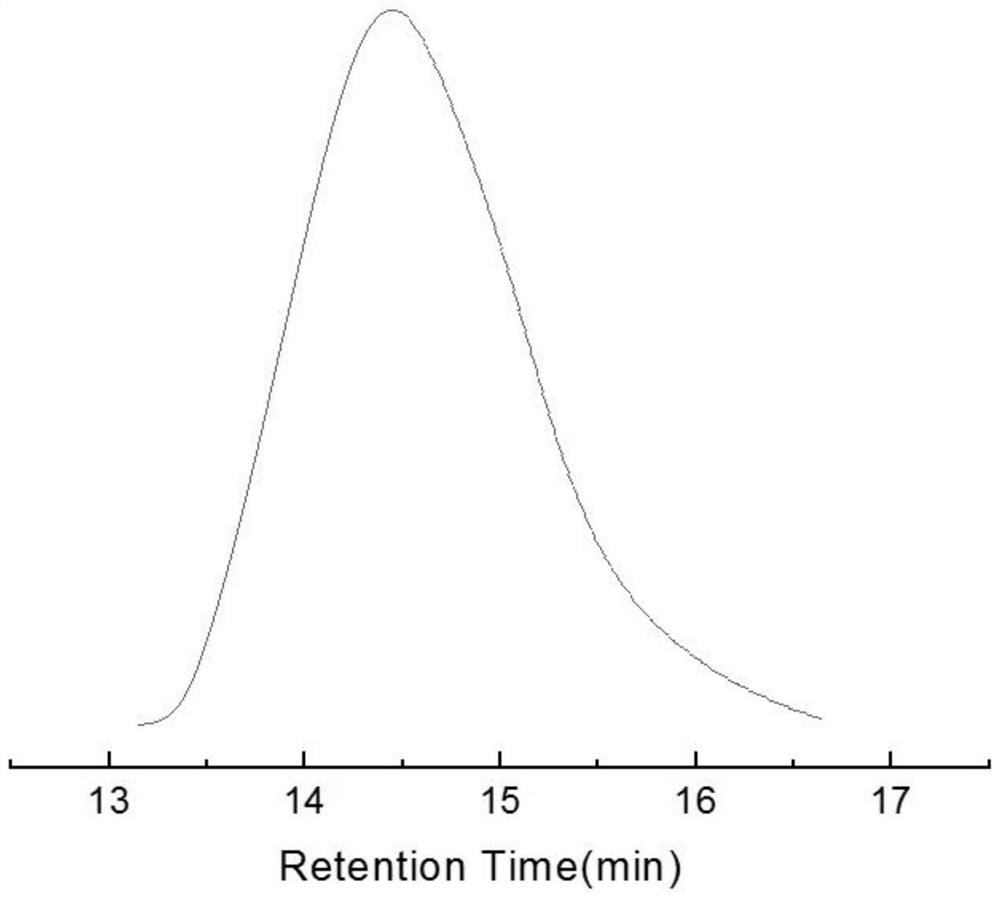

[0031] Polypropylene macromolecular chain transfer agent (0.1mmol), colorant (10mmol), AIBN (0.01mmol) and 5mL dioxane prepared in Example 1 were added in the 10ml Schlenk bottle with stirring bar respectively, and The temperature of the oil bath was set to 75°C. After three cycles of liquid nitrogen freezing-pumping-thawing, the Schlenk bottle was placed in the oil bath reaction pot for polymerization reaction. After 4 hours of reaction, the Schlenk bottle was immediately taken out and placed in liquid nitrogen to cool. The crude product was repeatedly precipitated in anhydrous ether, and the precipitate was filtered and vacuum-dried to obtain a colored polypropylene block copolymer with a yield of 71.6%.

Embodiment 3

[0033] Put 60 parts by mass of colored polypropylene block copolymer and 2 parts by mass of silver ion antibacterial agent in a 5mL volumetric flask, add n-octane to the mark, heat to 110°C to completely dissolve the polymer, and then use a spin coater to polymerize The solution is spin-coated on a clean glass substrate; finally, the colored antibacterial polypropylene film is vacuum-dried in a vacuum oven and the volatilized solvent is recovered to obtain a colored antibacterial polypropylene film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com