Flame-retardant polyurethane and preparation method thereof

A polyurethane and flame-retardant technology, applied in the field of flame-retardant polyurethane and its preparation, can solve the problems of easy migration, low hardness, poor matrix compatibility, etc., and achieve the effect of simple process, good performance and long-lasting flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

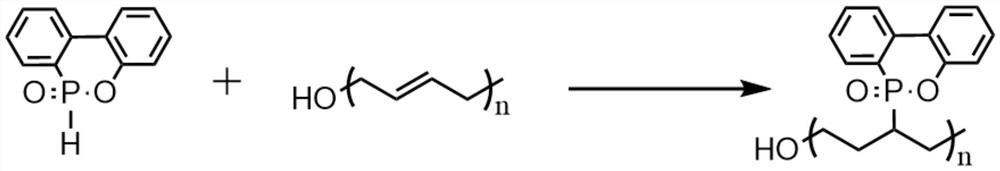

Method used

Image

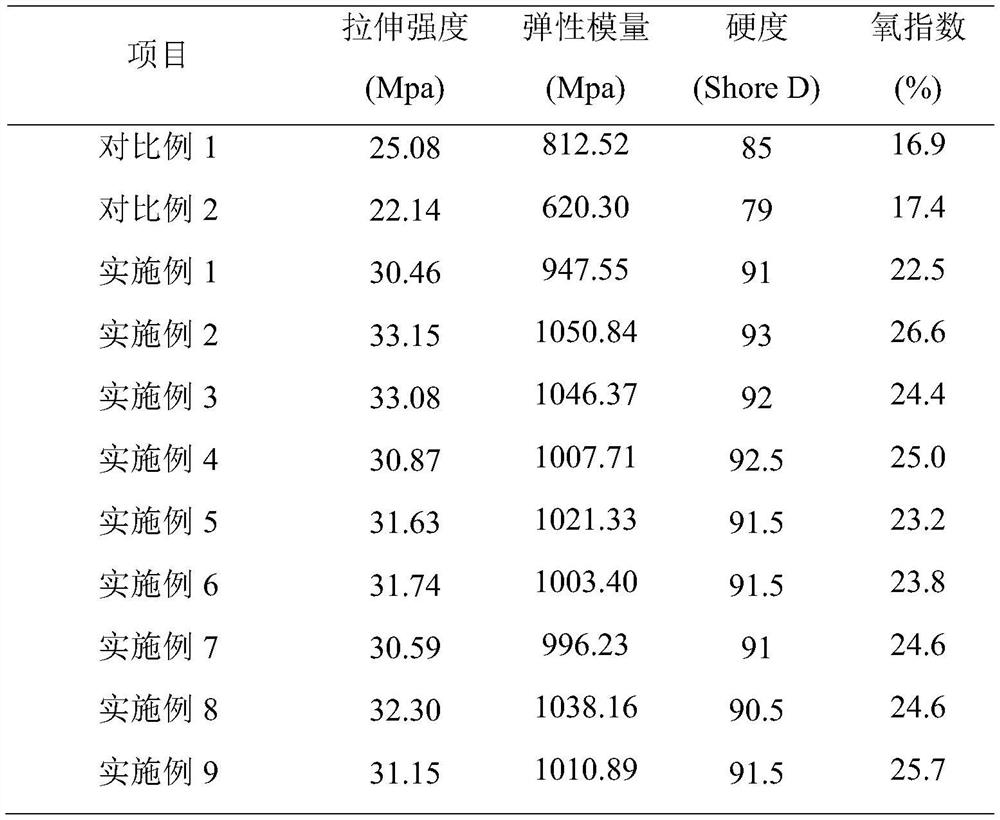

Examples

Embodiment 1

[0032] (1) Preparation of component A

[0033] In parts by weight, 50 parts of hydroxyl-terminated polybutadiene, 10 parts of polycaprolactone diol, 30 parts of polypropylene glycol, 10 parts of trimethylolpropane, 5 parts of 9,10-dihydro-9-oxygen Hetero-10-phosphaphenanthrene-10-oxide was stirred at 1000 rpm and vacuum at 120°C for 3 hours, mixed evenly and cooled to 50°C to obtain the component A.

[0034] (2) Take 56 parts of component A and 40 parts of component B (4,4'-diphenylmethane diisocyanate) in the same container, and stir at room temperature for 5 minutes until the mixture is uniform to obtain a solvent-free two-component polyurethane.

Embodiment 2

[0036] (1) Preparation of component A

[0037] In parts by weight, 60 parts of hydroxyl-terminated polybutadiene, 10 parts of polycaprolactone triol, 10 parts of polypropylene glycol, 5 parts of trimethylolethane, 10 parts of 9,10-dihydro-9- Oxa-10-phosphaphenanthrene-10-oxide, stirred at 1500 rpm and vacuum at 100°C for 3 hours, mixed uniformly and cooled to 70°C to obtain the component A.

[0038] (2) Take 60 parts of component A and 40 parts of component B (toluene diisocyanate) in the same container, stir at room temperature for 6 minutes until they are evenly mixed to obtain a solvent-free two-component polyurethane.

Embodiment 3

[0040] (1) Preparation of component A

[0041] In parts by weight, 40 parts of hydroxyl-terminated polybutadiene, 25 parts of polycaprolactone diol, 25 parts of polypropylene glycol, 10 parts of trimethylolpropane, 10 parts of 9,10-dihydro-9-oxygen Hetero-10-phosphaphenanthrene-10-oxide was stirred at 1600 rpm and vacuum at 110°C for 2.5 hours, mixed evenly and cooled to 50°C to obtain the component A.

[0042] (2) Take 60 parts of component A and 40 parts of component B (toluene diisocyanate) in the same container, stir at room temperature for 8 minutes until they are evenly mixed to obtain a solvent-free two-component polyurethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com