Preparation method for closed-type aliphatic-series isocyanate water dispersoid

An isocyanate and aliphatic technology, applied in the field of preparation of closed aliphatic isocyanate water dispersion, can solve problems such as low bonding or bonding strength, and achieve the effect of simplifying the use process and stabilizing the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: the preparation method of blocked aliphatic isocyanate water dispersion in the present embodiment is carried out according to the following steps:

[0025] Step 1, drying the polyol at 60-100°C;

[0026] Step 2, add 0.5~1.5mol polyhydric alcohol, 0.2~0.8molDMPA (dimethylol propionic acid) into 10~250mL composite solvent, described composite solvent is by solvent A and solvent B according to the ratio of 1: (3~10) The volume ratio is mixed at room temperature, the solvent A is acetone, the solvent B is ethyl acetate or dichloromethane, stirred for 10-60 minutes, and then nitrogen gas is passed through at a flow rate of 3-15mL / min for 15-45 minutes (the purpose is to remove the solution Oxygen in), then heated to 50-95°C and kept warm for 15-45 minutes;

[0027] Step 3, then dropwise add 0.5-2mol aliphatic isocyanate, the dropping rate is controlled at 2-5s / drop, and then react at 50-95°C for 0.5-7 hours;

[0028] Step 4, then add a blocking age...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment is different from Embodiment 1 in that: the polyol described in step 1 is polyester polyol or polyether polyol. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the polyhydric alcohol described in step one is polyoxypropylene glycol, polyethylene oxide glycol, polyethylene glycol, polyethylene adipate two alcohol, polycaprolactone or poly-2,3-dimethyl-2,3-butanediol. Other steps and parameters are the same as in the first embodiment.

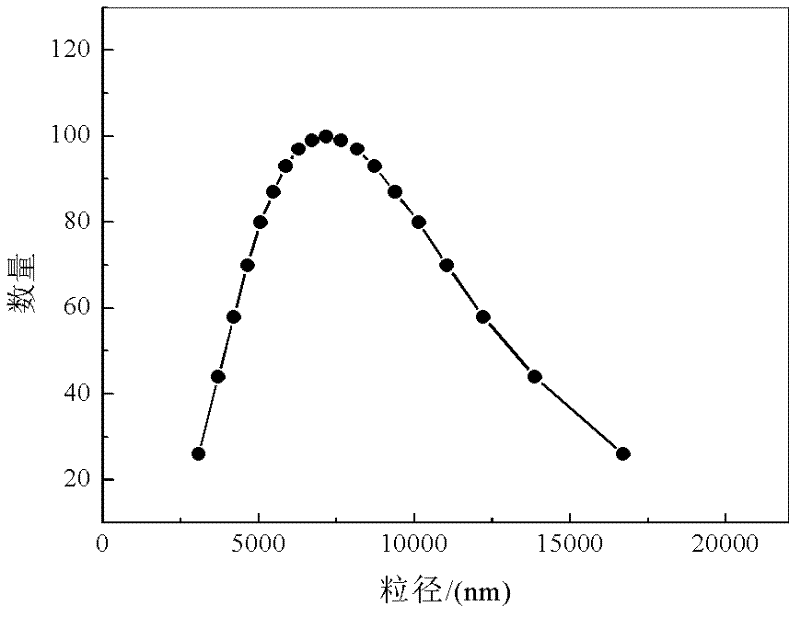

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com