Lens for glasses and process for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

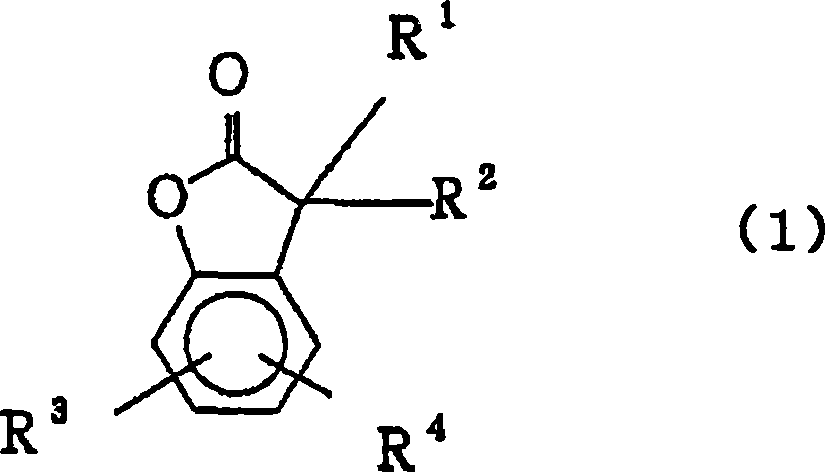

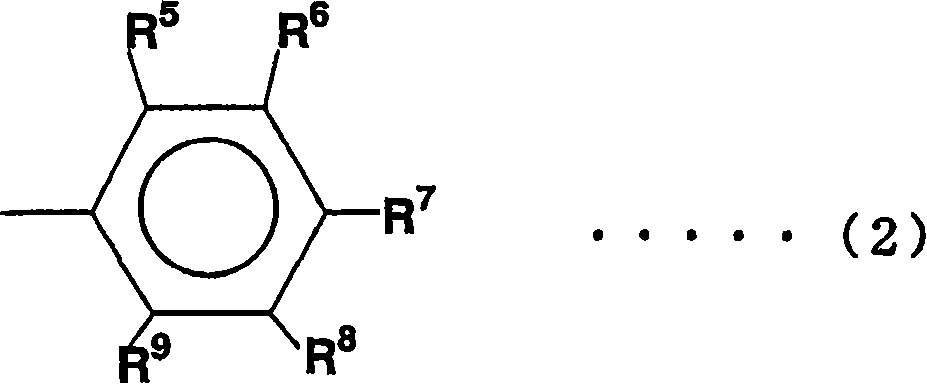

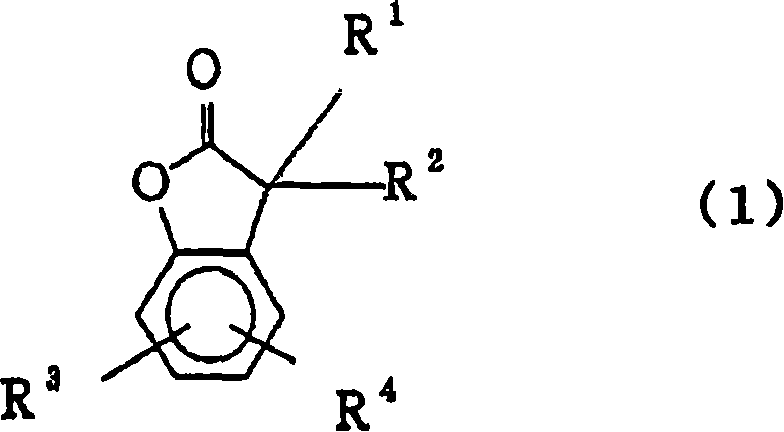

[0083] 2-(2'-Hydroxy-5' -0.3 parts of tert-octylphenyl)benzotriazole (maximum absorption is 340nm), add 2,2'-methylenebis[4-(1,1,3,3- Tetramethylbutyl)-6-(2H-benzotriazol-2-yl)phenol] (maximum absorption is 349nm) 0.04 parts, add 5,7-di-tert-butyl- 3-(3,4-dimethylphenyl)-3H-benzofuran-2-one (in the aforementioned formula (1), R 1 is a hydrogen atom, R 2 is 3,4-dimethylphenyl, R 3 and R 4 0.0027 parts of a compound represented by a tert-butyl group), 0.25 parts of stearyl stearate (release agent), 0.03 parts of the following phosphorus-based stabilizer (e) and a compound represented by the following formula as a bluing agent 0.5ppm,

[0084]

[0085] After fully mixing with a roller, granulate (new raw material pellets) at 260-280° C. with a 30 mm vented extrusion molding machine. In order to study the hue of the recycled raw material pellets, the re-granulated pellets were obtained by performing two consecutive granulations under the same extrusion conditions. These ...

Embodiment 2

[0091] Change the amount of 5,7-di-tert-butyl-3-(3,4-dimethylphenyl)-3H-benzofuran-2-one in Example 1 to 0.01 parts, except The same operation as in Example 1 was carried out to obtain a sample plate, and the evaluation results are shown in Table 1.

Embodiment 3

[0093] Change the addition amount of 5,7-di-tert-butyl-3-(3,4-dimethylphenyl)-3H-benzofuran-2-one in Example 1 to 0.05 parts, in addition The same operation as in Example 1 was carried out to obtain a sample plate, and the evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com