Vinyl acetate-acrylate copolymer emulsion, its synthesis method and application

A technology of vinyl acetate and acrylate, applied in the direction of monocarboxylic acid ester copolymer adhesive, ester copolymer adhesive, adhesive type, etc., can solve the problem of complex preparation process, increased product cost, and volatilization of organic solvents etc. to achieve good transparency, low coating viscosity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

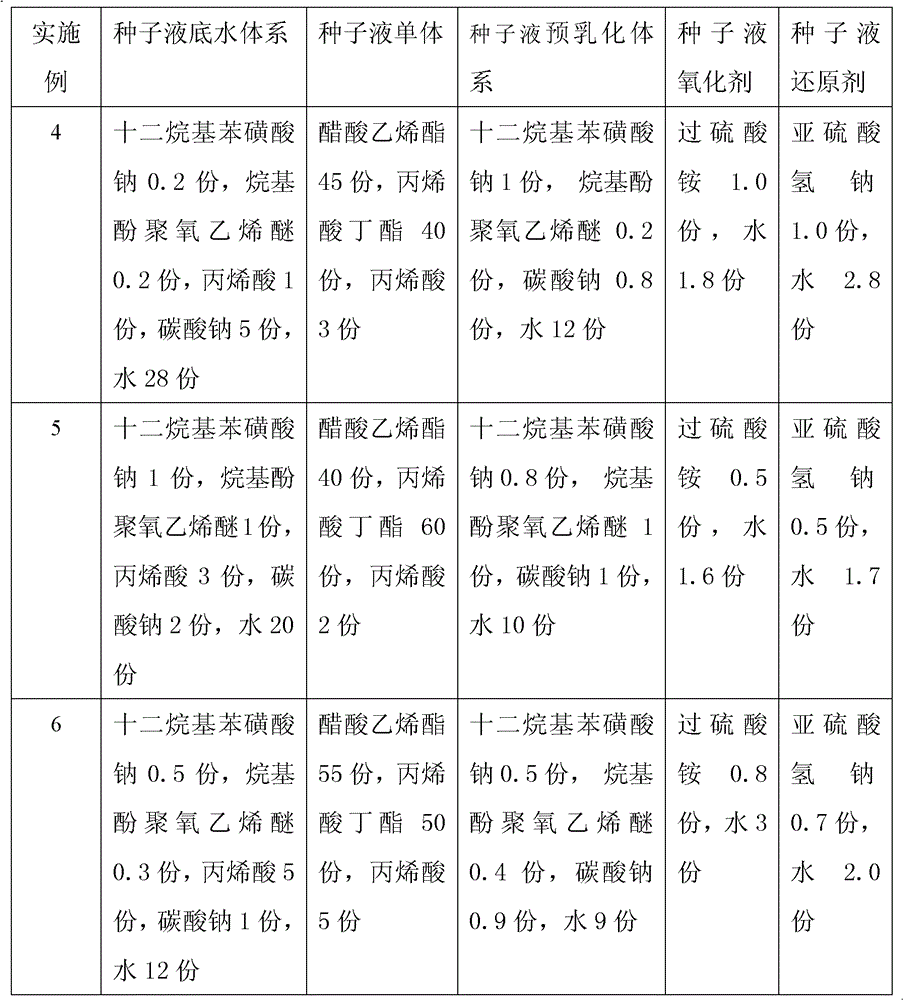

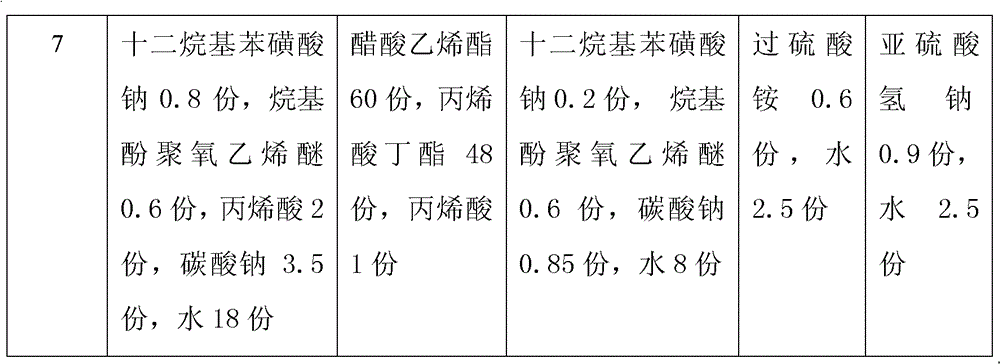

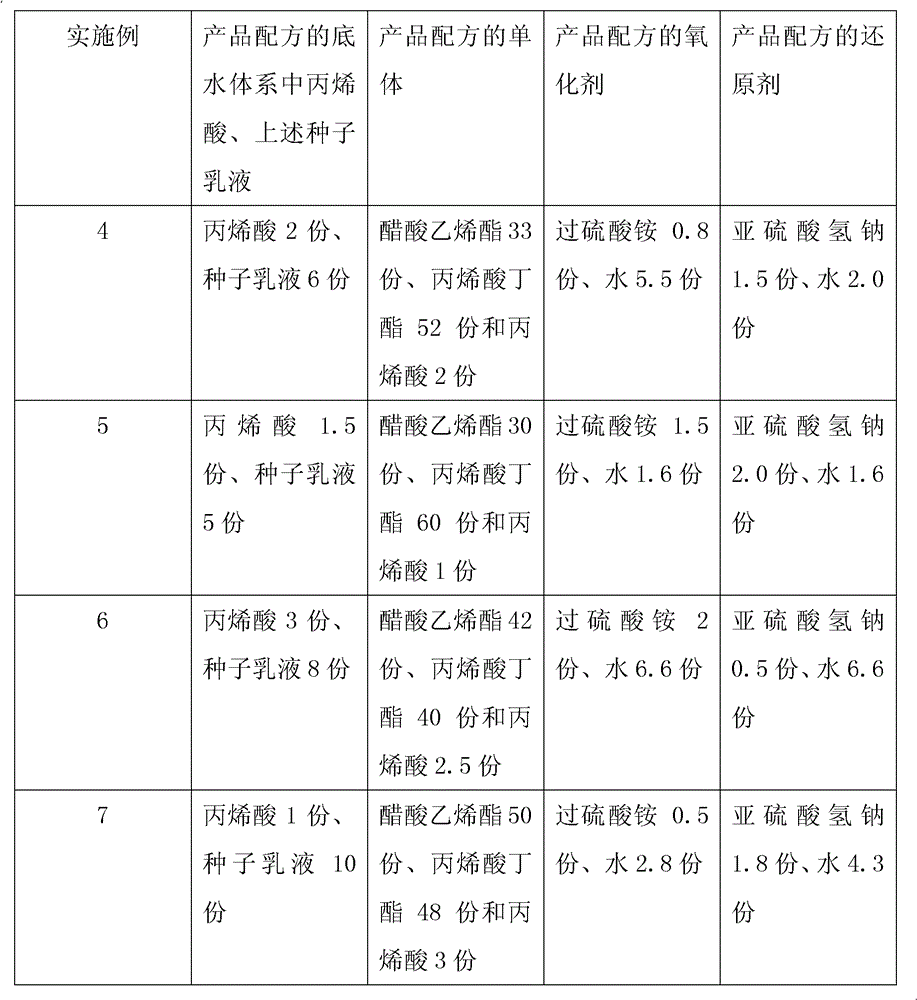

Examples

Embodiment 1

[0032] A kind of vinyl acetate-acrylic acid ester copolymerization emulsion, adopts following raw material to make:

[0034] Bottom water system: 0.2 parts of SDBS sodium dodecylbenzene sulfonate, 0.2 parts of Op-10 alkylphenol polyoxyethylene ether, 1 part of AA acrylic acid, Na 2 CO 3 1 part of sodium carbonate, 12 parts of water;

[0035] Monomer: 40 parts of vinyl acetate, 40 parts of butyl acrylate, 1 part of acrylic acid;

[0036] Pre-emulsion system: 0.2 part of SDBS sodium dodecylbenzene sulfonate, 0.2 part of Op-10 alkylphenol polyoxyethylene ether, Na 2 CO 3 0.8 parts of sodium carbonate, 8 parts of water;

[0037] Initiation systems include oxidizing and reducing agents:

[0038] Oxidant: 0.5 parts of APS ammonium persulfate, 1.6 parts of water;

[0039] Reducing agent: 0.5 parts of SHS sodium bisulfite, 1.6 parts of water.

[0040] product ingredients:

[0041] Bottom water: 0.5 parts of OP-10 / SDBS sodium dodecylbenzene sulfonate...

Embodiment 2

[0057] A kind of vinyl acetate-acrylic acid ester copolymerization emulsion, adopts following raw material to make:

[0059] Bottom water system: 0.5 parts of SDBS sodium dodecylbenzene sulfonate, 0.5 parts of Op-10 alkylphenol polyoxyethylene ether, 3 parts of AA acrylic acid, Na 2 CO 3 3 parts of sodium carbonate, 20 parts of water;

[0060] Monomer: 50 parts of vinyl acetate, 50 parts of butyl acrylate, 3 parts of acrylic acid;

[0061] Pre-emulsion system: 0.5 part of SDBS sodium dodecylbenzene sulfonate, 0.5 part of Op-10 alkylphenol polyoxyethylene ether, Na 2 CO 3 0.9 parts of sodium carbonate, 10 parts of water;

[0062] Initiation systems include oxidizing and reducing agents:

[0063] Oxidant: 0.7 parts of APS ammonium persulfate, 2.3 parts of water,

[0064] Reducing agent: 0.7 parts of SHS sodium bisulfite, 2.3 parts of water.

[0065] product ingredients:

[0066] Bottom water: OP-10 / SDBS sodium dodecylbenzenesulfonate / SVS sod...

Embodiment 3

[0080] A kind of vinyl acetate-acrylic acid ester copolymerization emulsion, adopts following raw material to make:

[0082] Bottom water system: SDBS sodium dodecylbenzene sulfonate 1 part, Op-10 alkylphenol polyoxyethylene ether 1.0 parts, AA acrylic acid 5 parts, Na 2 CO 3 5 parts of sodium carbonate, 28 parts of water;

[0083] Monomer: 60 parts of vinyl acetate, 60 parts of butyl acrylate, 5 parts of acrylic acid;

[0084] Pre-emulsion system: SDBS sodium dodecylbenzene sulfonate 1 part, Op-10 alkylphenol polyoxyethylene ether 1.0 part, Na 2 CO 3 1.0 parts of sodium carbonate, 12 parts of water;

[0085] Initiation systems include oxidizing and reducing agents:

[0086] Oxidant: 1.0 parts of APS ammonium persulfate, 3.0 parts of water,

[0087] Reducing agent: 1.0 parts of SHS sodium bisulfite, 3.0 parts of water.

[0088] product ingredients:

[0089] Bottom water: OP-10 / SDBS sodium dodecylbenzene sulfonate / SVS sodium vinyl sulfonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com