Curing agent toluene diisocyanate and 4,4'-methyl diphenylene diisocyanate mixing prepolymer and preparation thereof

A technology of toluene diisocyanate and diphenylmethane is applied in the field of adhesive curing agent prepolymer and its preparation, and in the field of polyurethane coating, and achieves the effects of simple process method, adjustable room temperature curing speed and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

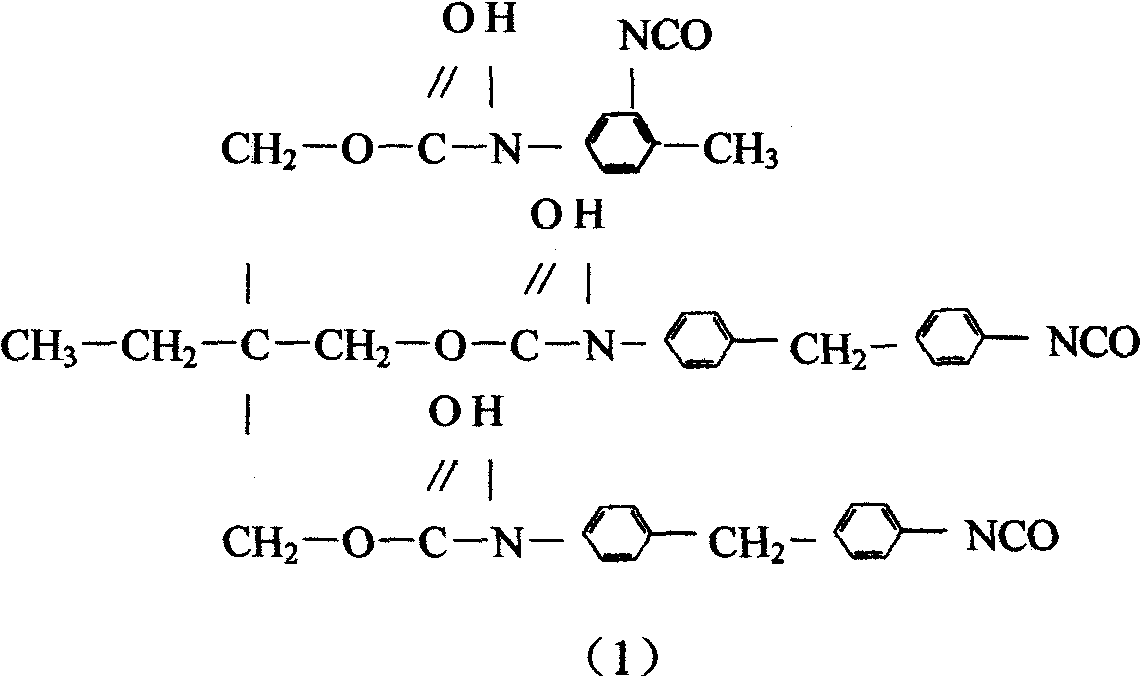

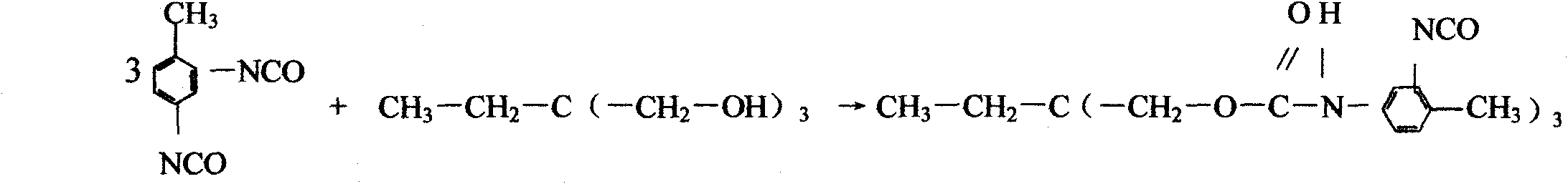

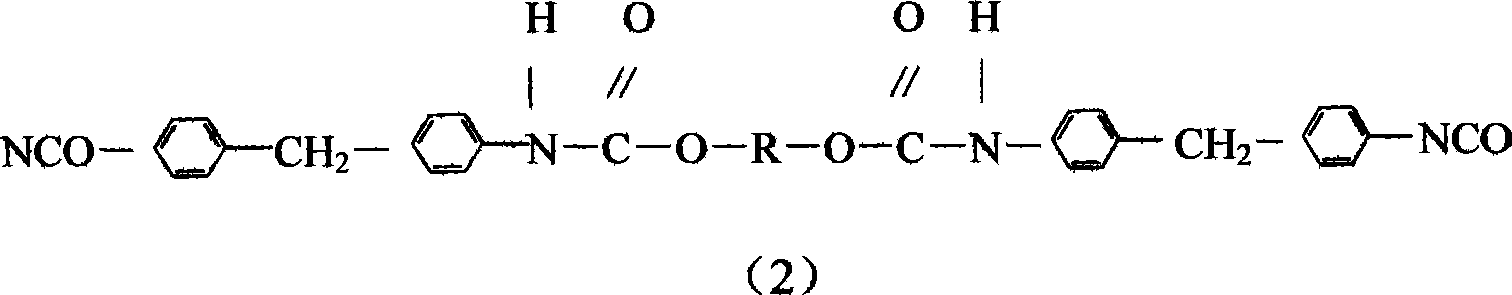

Method used

Image

Examples

Embodiment 1

[0046] a. Add 200 grams of melted 4,4'-MDI and 200 grams of ethyl acetate into the reaction kettle, stir evenly, heat up to 65°C, add 112 grams of alkyd resin dehydrated under vacuum, at 60~70°C React for 2 hours and react at 90-100°C for 2 hours; b. Add 200 grams of TDI under stirring, and after mixing uniformly, cool to below 80°C, dropwise add 68.4 grams of trimethylolpropane and 68.4 grams of ethyl acetate. The mixed solution is dripped in 2 hours. At 60~70℃, keep for 4 hours, then increase to 80~90℃, keep for 2 hours and cool down; c. Add 312 grams of toluene solvent according to the product solid content requirement, stir evenly, The material obtained 1160.8 grams of TDI-MDI mixed curing agent with a solid content of 50%, and the NCO content of the curing agent was tested to be 7.0% (14.0% based on total solids).

[0047] (Note: 1. The detection of solid content is carried out according to the national standard "GB / T 2793-1995 Determination of Non-volatile Content of Adhesi...

Embodiment 2

[0049] a. Add 150 grams of melted 4,4'-MDI and 60 grams of ethyl acetate into the reactor, stir evenly, heat up to 65°C, add 142.5 grams of phthalic anhydride polyester polyol dehydrated by vacuum, at 60~70 React at ℃ for 2 hours and at 90-100 ℃ for 2 hours; b. Add 93.8 grams of TDI with stirring. After mixing uniformly, cool to below 80 ℃, drop 27 grams of trimethylolpropane and 27 grams of ethyl acetate The composition of the mixed liquid, drip in 2 hours, keep at 60~70℃, keep for 4 hours, then increase to 80~90℃, keep for 2 hours, cool down; c. Add 220g xylene and 106g according to the product solid content requirement The cyclohexanone solvent was stirred uniformly, and 826 grams of TDI-MDI mixed curing agent with a solid content of 50% was obtained. The NCO content of the curing agent was tested to be 5.7% (11.5% based on total solids).

Embodiment 3

[0051] a. Add 200 grams of melted 4,4'-MDI and 50 grams of ethyl acetate into the reaction kettle, stir evenly, heat up to 65°C, add 30 grams of polyoxypropylene glycol dehydrated under vacuum, at 70~80 React for 2 hours at ℃, then add 30 grams of polyethylene adipate diethylene glycol diethylene glycol which is dehydrated under vacuum, react at 80~90℃ for 1 hour, and at 90~100℃ for 1 hour ; B. Add 72 grams of TDI with stirring, after mixing uniformly, cool to below 80 ℃, dropwise add 48.2 grams of trimethylolpropane and 48.2 grams of ethyl acetate mixture, drip in 4 hours, at 70 ~ 80 ℃ , The temperature is kept for 2 hours, then the temperature is raised to 80~90℃, the temperature is kept for 3 hours, and the temperature is lowered; c. Add 29 grams of butyl acetate solvent according to the product solid content requirements, stir evenly, and discharge 507 grams of solid content with 75% viscosity. 2200mpa.s (25°C) TDI-MDI mixed curing agent, the NCO content of the curing agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com