Anti-yellowing nano-silver antibacterial polycarbonate material and formed product thereof

A nano-silver antibacterial and polycarbonate technology is applied in the field of yellowing-resistant nano-silver antibacterial polycarbonate materials and their molded products, which can solve problems such as affecting the qualified rate of injection molded products, inconsistent product colors, and yellowing of plastics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

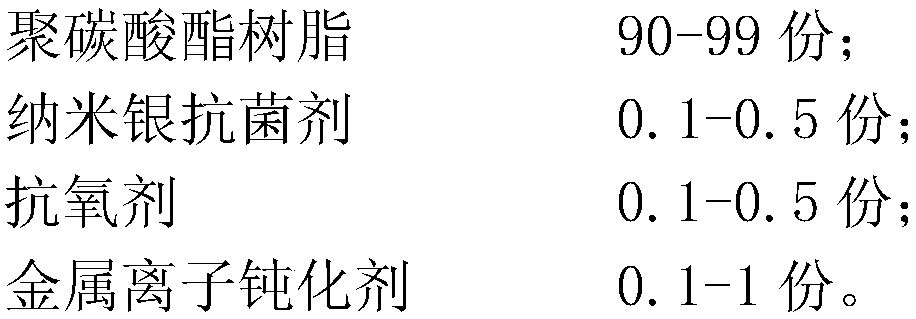

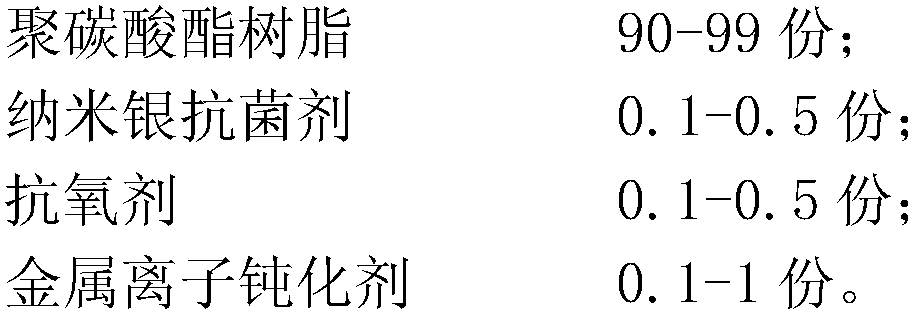

[0025]

[0026] In Example 1, the melt index of the polycarbonate resin was 6g / 10min (260°C, 130Kg), and each component of the corresponding weight was weighed; then, each component was stirred with a uniaxial stirring bucket; The mixture was separately fed into a twin-screw extruder for melt extrusion and pelletization.

Embodiment 2

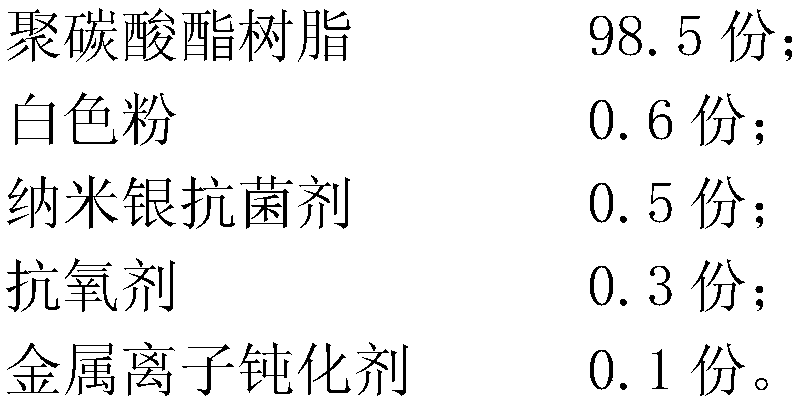

[0036]

[0037] In Example 2, the melt index of the polycarbonate resin was 12g / 10min (260°C, 130Kg), and each component of the corresponding weight was weighed; then, each component was stirred with a uniaxial stirring bucket; The mixture was separately fed into a twin-screw extruder for melt extrusion and pelletization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com