Method for producing antimonous oxide by wet method to improve whiteness

A technology of antimony trioxide and whiteness, used in chemical instruments and methods, inorganic chemistry, antimony compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

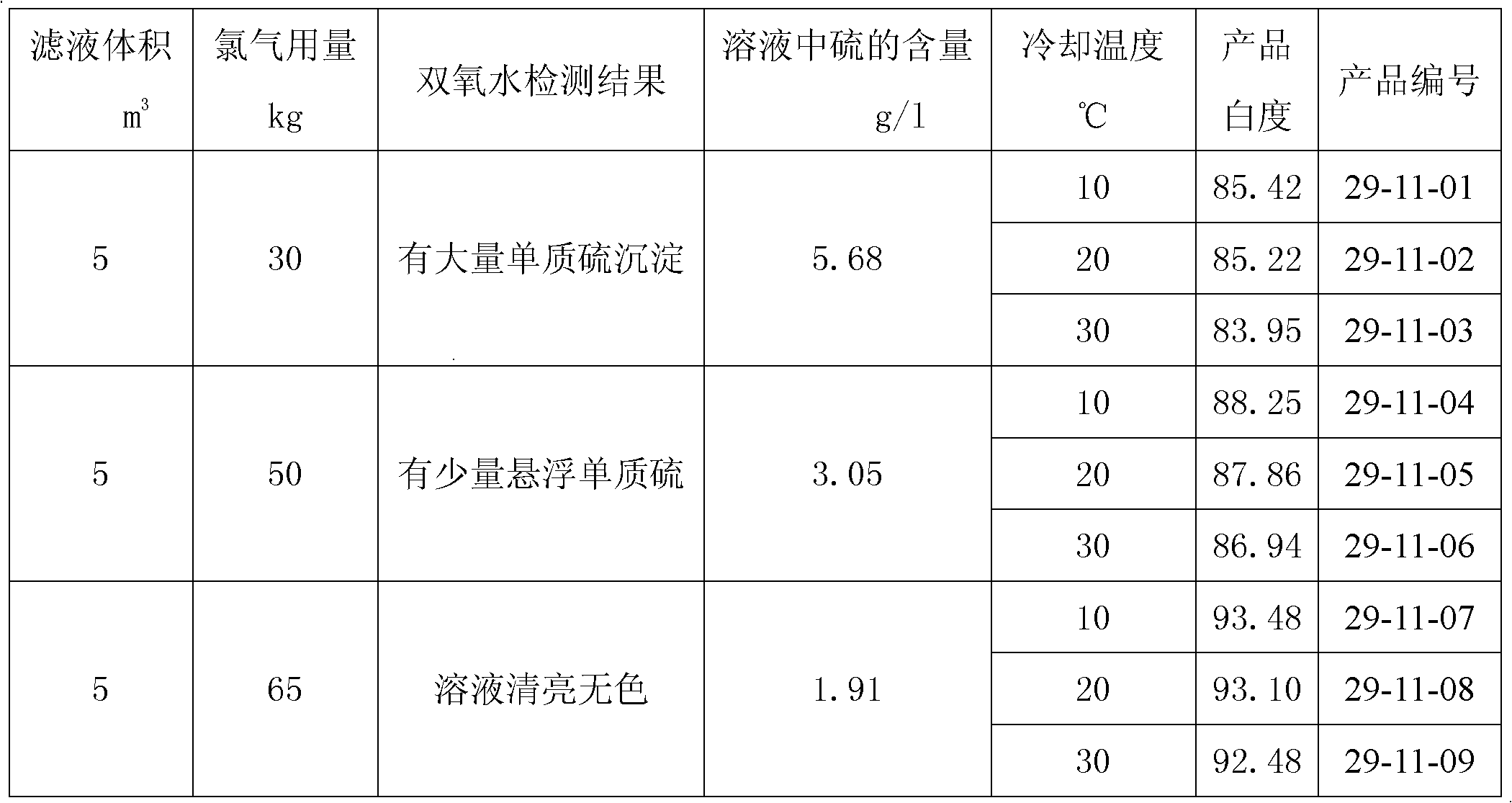

[0032] The following examples are intended to further illustrate the present invention, rather than limit the present invention.

[0033] Table 1 Raw ore composition

[0034] name

Sb

Au

Pb

As

Cu

H 2 0

Fuxing, You County, Hunan

54.50

0.67g / t

0.37%

0.49%

0.015%

12.1%

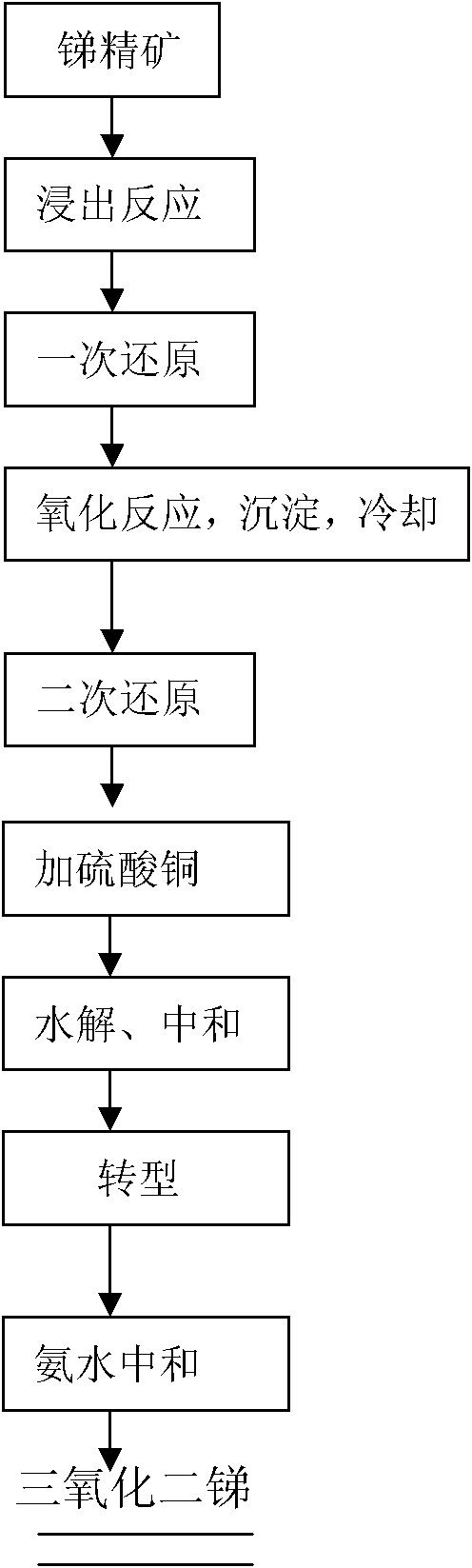

[0035] The flow process of industrialized production of the present invention is as follows:

[0036] Add the chlorinated leaching solution of the above-80 mesh antimony sulfide concentrate (chlorination leaching adopts the chlorination leaching method of the invention patent CN 1041787A) to the antimony sulfide concentrate for primary reduction; pass excessive chlorine gas into the filtrate for oxidation, and the oxidation reaction temperature is 50- 90°C; react until elemental sulfur is precipitated and the solution is bright reddish brown, filter, precipitate for no less than 2 hours, filter, and cool to 10-40°C. The cooled solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com