Ultrasonic consumable electrode argon arc welding process and device

A melting electrode and argon arc welding technology, which is applied in the field of argon arc welding, can solve the problems of ineffective fusion of molten metal, achieve the effects of complete gas precipitation, refinement of metal grains, and improvement of fatigue strength and fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

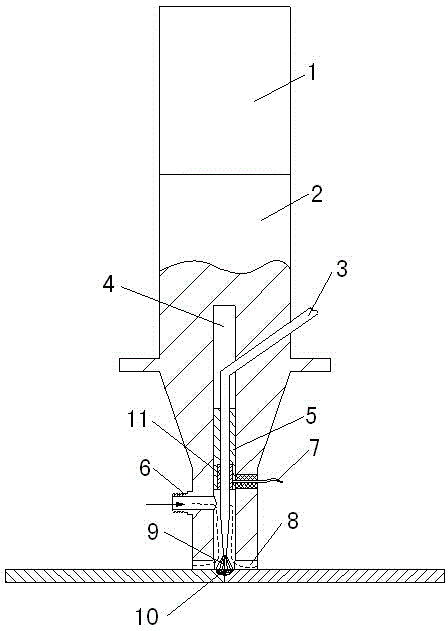

[0016] Ultrasonic melting electrode argon arc welding device of the present invention such as figure 1 As shown, it mainly includes a transducer 1 and a horn 2, the transducer 1 is fixedly connected to one end of the horn 2, and an electrode cavity 4 is arranged at the other end of the horn 2, and a conductive The nozzle 11 is provided with an insulating layer 5 between the conductive nozzle 11 and the electrode cavity 4 . The side of the horn 2 is provided with an air inlet 6 and a wire inlet, the air inlet 6 communicates with the electrode cavity 4, the wire 7 connected to the contact tip 11 is drawn out from the wire inlet, and the insulating layer 5 is filled between the wire 7 and the wire inlet . The side of the horn 2 is also provided with an electrode inlet. The melting electrode 3 enters the electrode chamber 4 of the horn 2 through the electrode inlet, and penetrates the conductive tip 11, protrudes from the conductive tip 11, and welds with the workpiece to be weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com