Polyurethane curing agent with low free isocyanate monomer and preparation method thereof

A polyurethane curing agent, isocyanate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of unfavorable polyurethane curing agent use, poor molecular weight distribution of products, low prepolymer NCO content, etc., to achieve excellent coating properties , Excellent resistance to yellowing, and the effect of improving leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

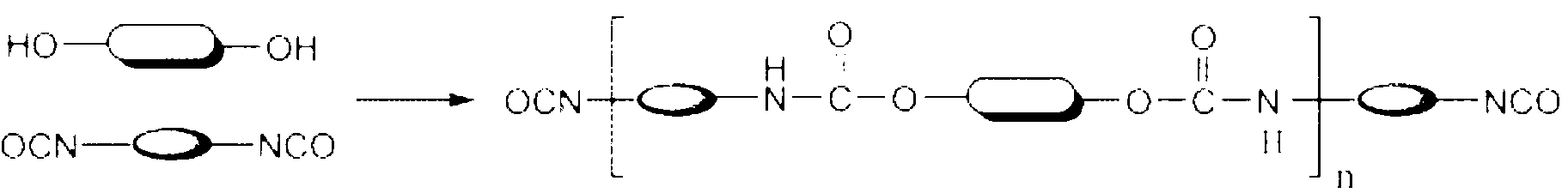

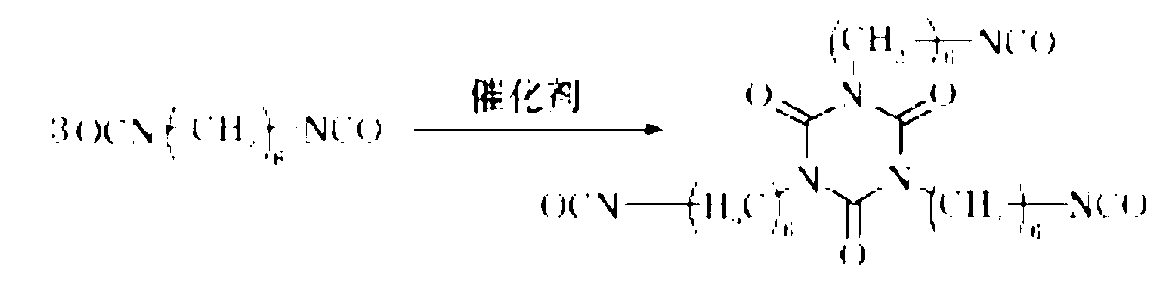

Method used

Image

Examples

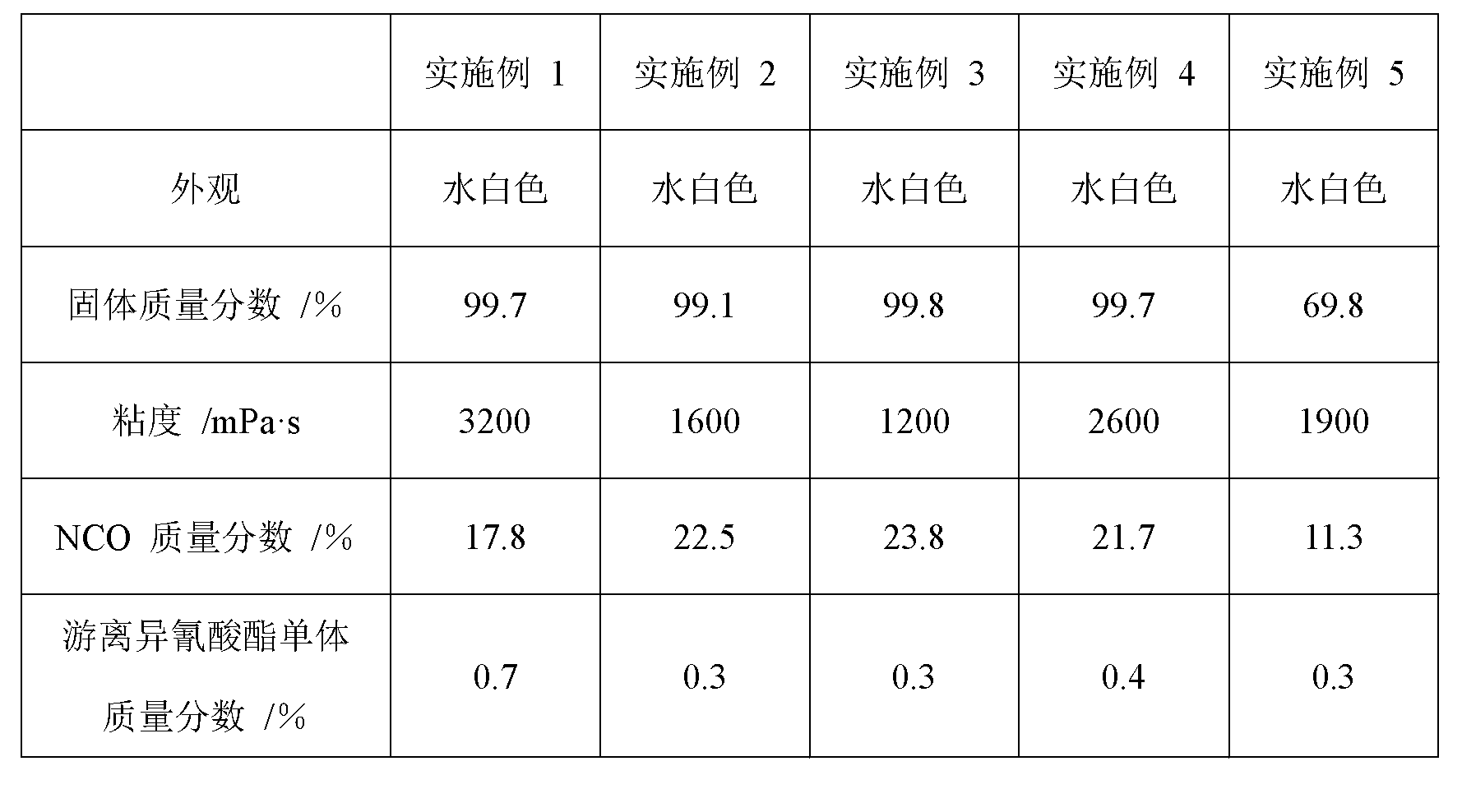

Embodiment 1

[0043] Under the protection of nitrogen, first put 168g of hexamethylene diisocyanate monomer into the reaction vessel and stir evenly, raise the temperature to 55°C, and then melt 22g of 2-ethyl-2-butyl 1,3-propanediol (BEPD) Then slowly add it dropwise into the reaction vessel under stirring condition, the dropwise time is 1 hour, after the dropwise addition is completed, keep it warm at 55°C for 2 hours, add 0.57g tri-n-butyltin oxide at one time, heat up to 70°C and continue Stir and react for 4 hours, when the NCO group content is reduced to 17.8 wt%, add 0.19g of phosphoric acid, keep warm at 70°C for 1 hour, cool and discharge to obtain a water-white viscous liquid polyurethane curing agent.

Embodiment 2

[0045] Under the protection of nitrogen, put 168g of hexamethylene diisocyanate monomer into the reaction vessel and stir evenly, raise the temperature to 65°C, then melt 42g of 1,4-cyclohexanedimethanol and slowly add it dropwise under stirring condition Into the reaction container, the dropwise addition time is 1.5 hours. After the dropwise addition, keep the temperature at 65°C for 4 hours, add 1g of quaternary ammonium salt (trade name DABCO TMR) at one time, raise the temperature to 80°C and continue stirring for 1 hour. The content of NCO groups was reduced to 22.5 wt%, and 0.5 g of benzoyl chloride was added, kept for 2 hours, cooled and discharged to obtain a water-white viscous liquid polyurethane curing agent.

Embodiment 3

[0047] Under the protection of nitrogen, put 168g of hexamethylene diisocyanate monomer into the reaction vessel and stir evenly, raise the temperature to 85°C, then melt 23g of 1,4-cyclohexanedimethanol and slowly add it dropwise under stirring condition Into the reaction vessel, the dropwise addition time is 1.5 hours. After the dropwise addition is completed, it is kept at 85°C for 4 hours, and 0.8g of 2,4,6-tris(dimethylaminomethyl)phenol (trade name DABCO) is added at one time. TMR-30), lower the temperature to 70°C and continue to stir and react for 4 hours. When the NCO group content is reduced to 23.8 wt%, add 0.5g phosphoric acid, keep warm for 1 hour, cool and discharge, and obtain a water-white viscous liquid polyurethane curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com