Patents

Literature

30results about How to "Reduce overreaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

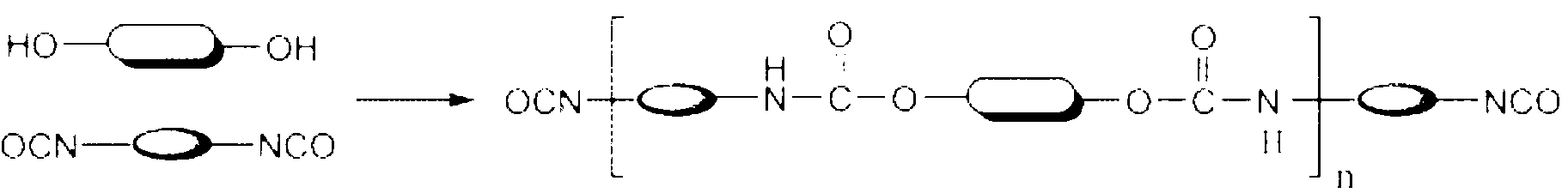

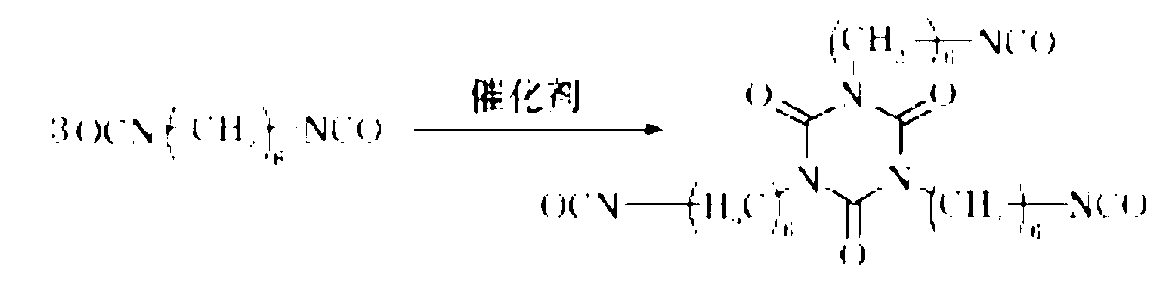

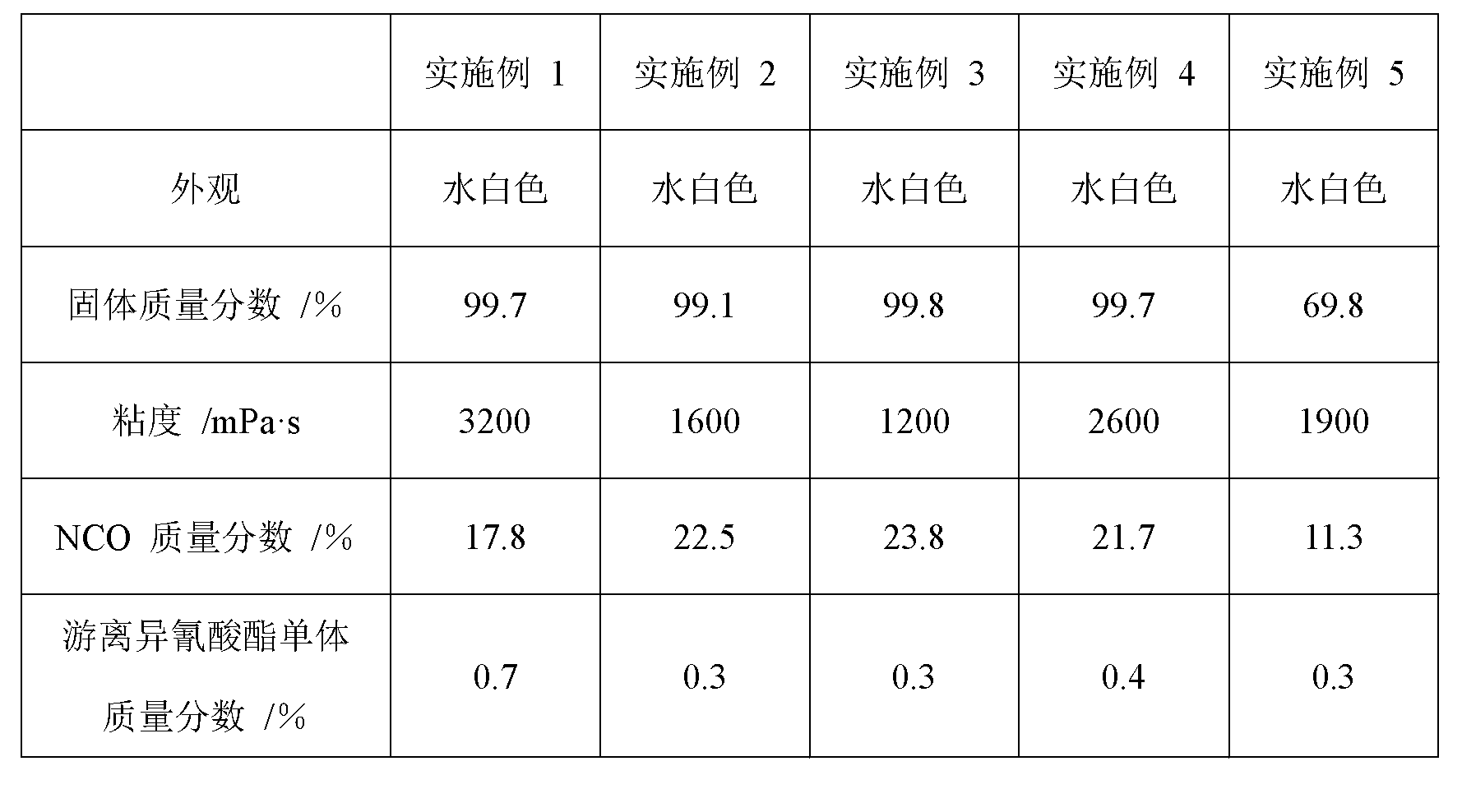

Polyurethane curing agent with low free isocyanate monomer and preparation method thereof

InactiveCN103224605AAdd one step polymerization reactionLow free HDI contentPolyurea/polyurethane coatingsPolymer scienceMeth-

The present invention relates to a polyurethane curing agent with low free isocyanate monomer and a preparation method thereof. The polyurethane curing agent comprises the raw materials in weight percentage as following: 80 - 88 parts of hexamethylene diisocyanate monomer; 12 - 20 parts of polyhydric alcohol; 0.1-0.5 part of catalyst; and 0.1-1.0 part of terminating agent. The invention adopts a two-step chemical conversion reaction, namely, adds one step of polymerization reaction based on one-step addition reaction to remove free isocyanate monomer by a trimer method so as to obtain the 100% solid content, wherein the NCO content is between 21 and 22 %, and the free HDI content is between 0.1 and 1.0 %. According to the present invention, the preparation process of polyurethane curing agent is simplified without post-processing . The polyurethane curing agent of the invention is matched with hydroxyl acrylic resin and polyester resin etc., and the paint film will not be yellowed, and has excellent light resistance, weathering resistance, chemical resistance and gorgeous gloss.

Owner:HUBEI TRASION CHEM IND CO LTD

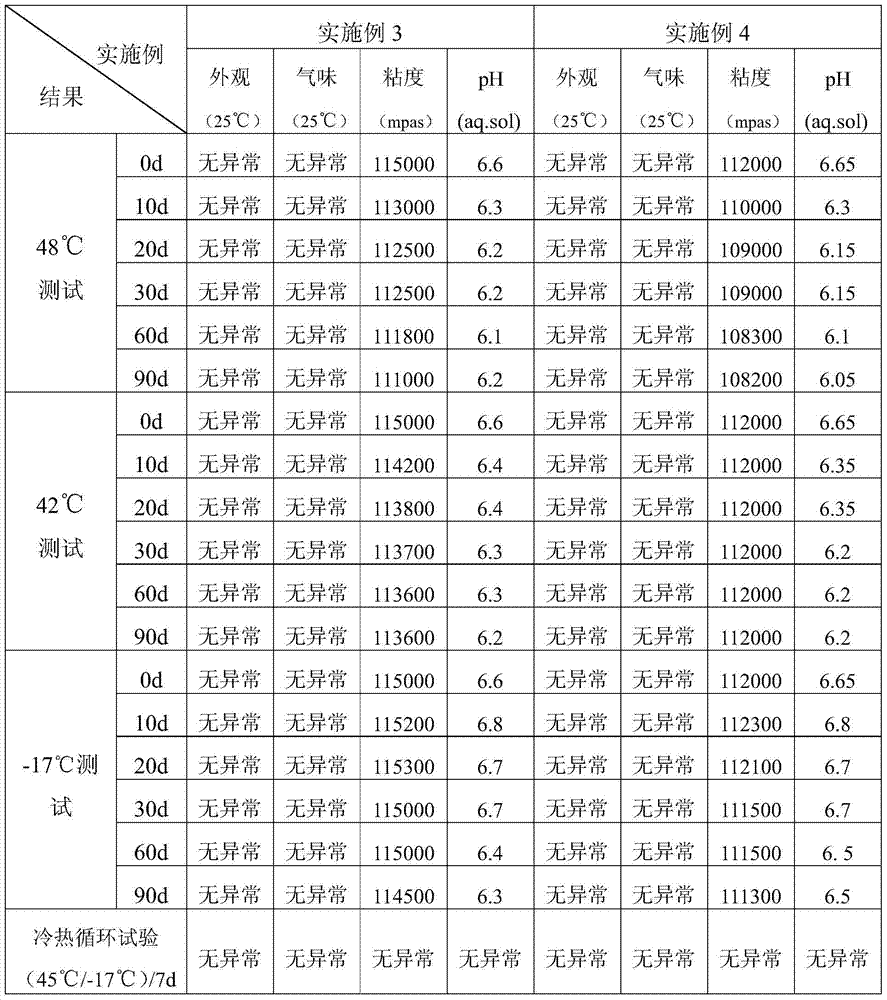

Face cream with anti-aging function and preparation method of face cream

ActiveCN104434747AMild in natureGood at scavenging free radicalsCosmetic preparationsToilet preparationsMedicineTremella

The invention discloses face cream with an anti-aging function and a preparation method of the face cream. The face cream disclosed by the invention contains hydrolyzed cod fish skin collagen, carboxymethyl chitosan, a tremella extract, oat-beta glucan and a composite plant anti-aging agent. The face cream with the anti-aging function disclosed by the invention is mild in property, natural and free of irritation and has a relatively good function of scavenging free radicals. By comprehensively applying various anti-aging policies, the face cream not only can be used as a skin care article for delaying senescence after aging, but also can be used as a daily skin care product for preventing aging. The face cream is obvious in anti-aging effect.

Owner:金日制药(中国)有限公司

Method for preparing vanadium-nitrogen alloy

The invention provides a method for preparing vanadium-nitrogen alloy. The method comprises the steps that vanadium oxide, graphite powder and a catalyst are evenly mixed, and the mixed materials are compressed to be spherical or elliptical raw materials; afterwards, the raw materials are placed in a sintering furnace full of nitrogen to be sintered, and the vanadium-nitrogen alloy can be obtained after sintering is completed; the catalyst is iron powder; the sintering process of the sintering furnace is that the temperature is made to rise to 1300-1500 DEG C, which is the highest temperature, within six hours; the vanadium oxide comprises at least one of vanadium pentoxide, vanadium tetraoxide and vanadium trioxide.

Owner:NANTONG HANRUI IND

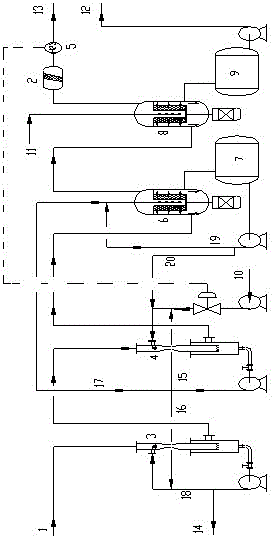

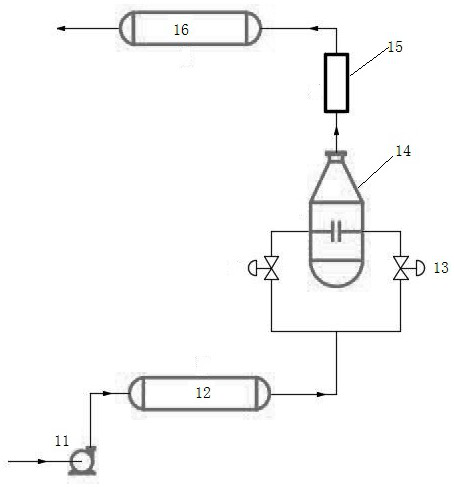

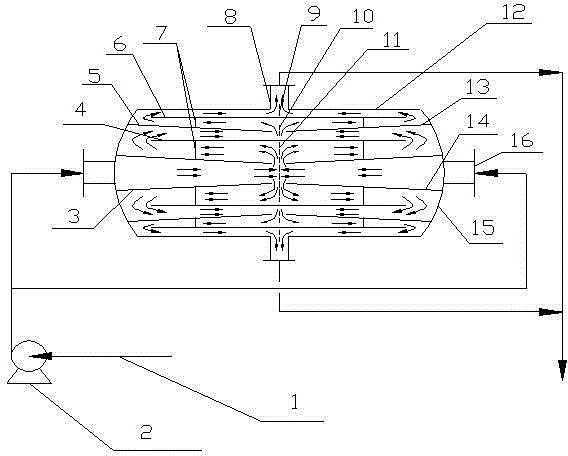

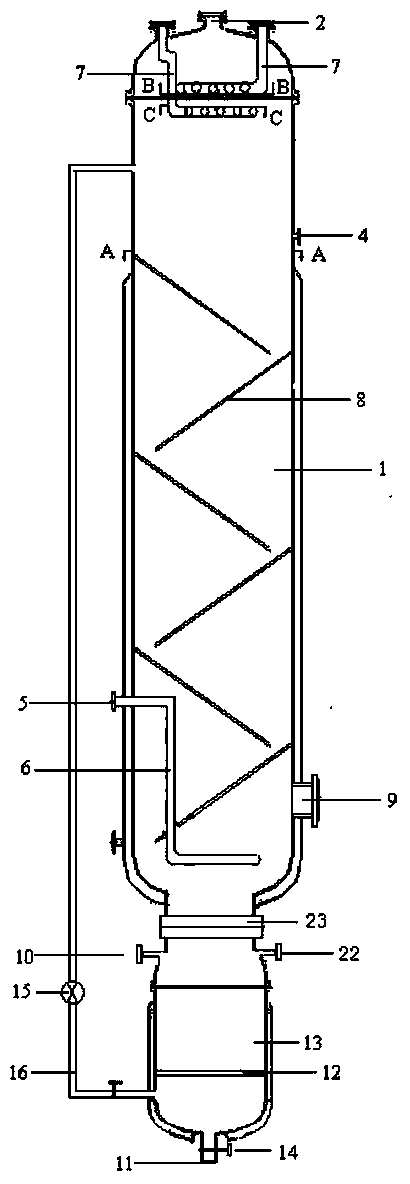

High-efficiency energy-saving xylene separation process

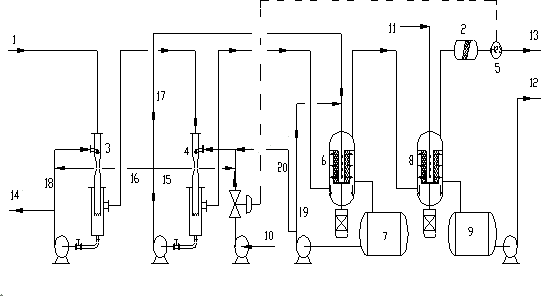

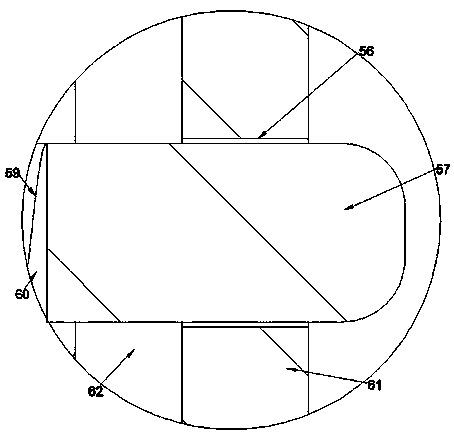

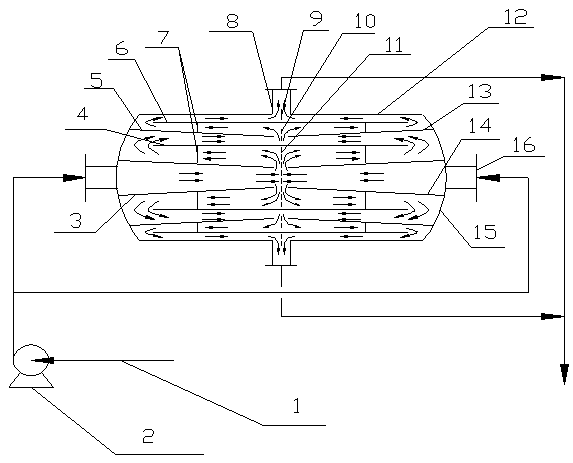

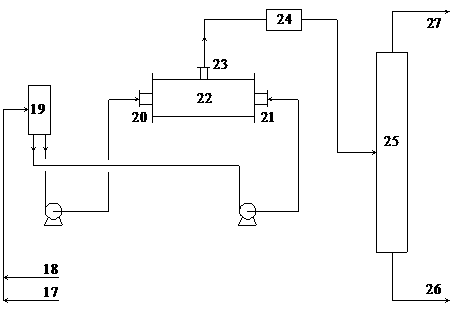

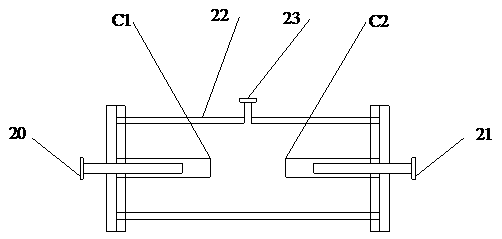

ActiveCN107519827AReduce volume utilizationExtended stayChemical/physical/physico-chemical nozzle-type rreactorsLiquid-liquid reaction processesRetention timeAromatic hydrocarbon

The invention discloses a process for separation and preparation of high-purity m-xylene from C8 aromatic hydrocarbon. An impinging stream reactor particularly suitable for the process is adopted, fluids are mixed through multiple impinging, good micromixing effect is achieved, the mixed liquid is pushed flatly and flows outside an impinging zone, adequate retention time is provided for the material, a cascade reaction is realized, and the target conversion rate is achieved through design of runners and the liquid flow velocity. The method overcomes the shortcoming that an impinging stream reactor cannot achieve high conversion rate through a single reactor at present, simplifies the technological process, reduces production cost and equipment investment, and ensures long-term operation of equipment. The method has no discharge of waste liquids in the production process, and is a green and environmental-friendly technological method.

Owner:CHINA PETROLEUM & CHEM CORP +1

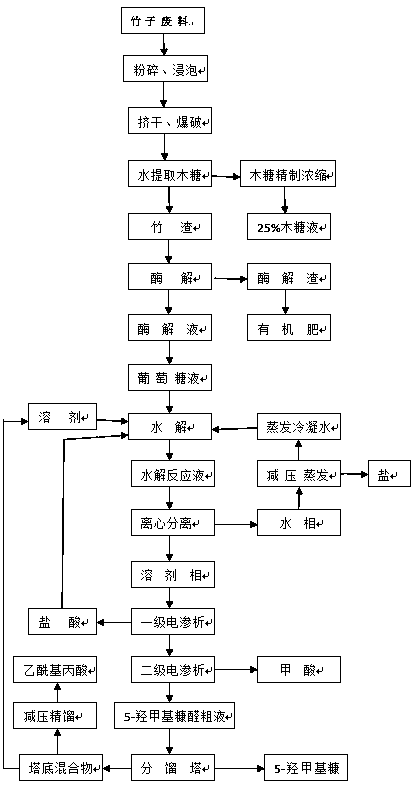

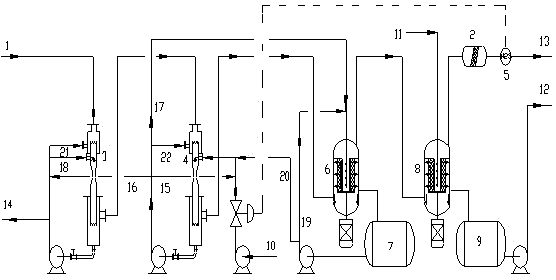

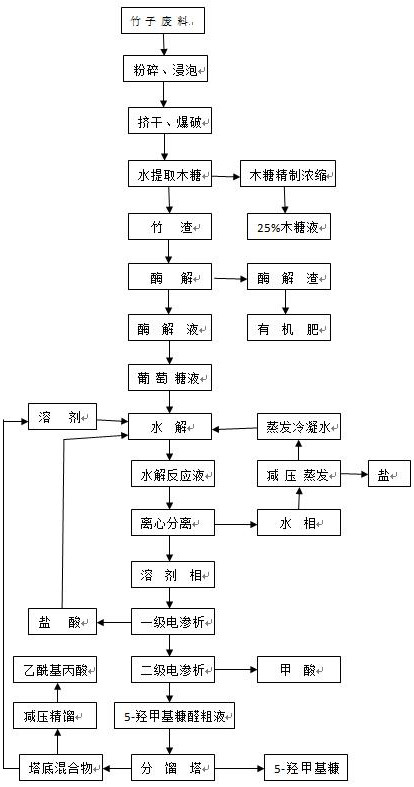

Method of producing 5-hydroxymethyl furfural

ActiveCN109439706AReduce energy consumptionPromote hydrolysis reactionXylose productionFermentationLiquid wasteUltrafiltration

The invention belongs to the field of chemical engineering and in particular relates to a method of producing 5-hydroxymethyl furfural. The method comprises the following steps: 1) crushing raw materials and then adding diluted sulfuric acid for soaking and extruding the raw materials; 2) carrying out steam explosion treatment on the extruded materials; 3) extruding the exploded materials after water extraction; 4) filtering the water extraction solution, and refining and concentrating the water extraction solution to obtain an xylose solution; 5) adding an enzyme into bamboo residues for enzymolysis and then carrying out filtration; 6) carrying out electrodialysis, and acetic acid and lignin impurity separation by an ultrafiltration membrane and a nanofiltration membrane on the obtained glucose hydrolysate to obtain a glucose solution; and 7) mixing the glucose solution with hydrochloric acid and sec-octyl alcohol in an emulsification pump; and feeding the mixture into an impinging stream reactor and a coupling device of a static mixer to react and the like. The method provided by the invention improves the yield and the production efficiency of 5-hydroxymethylfurfural prepared from glucose, an extraction solvent is omitted, the production cost and the equipment investment are lowered, and no waste liquor is discharged in the production process, so that the method is a green and environment-friendly process method.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

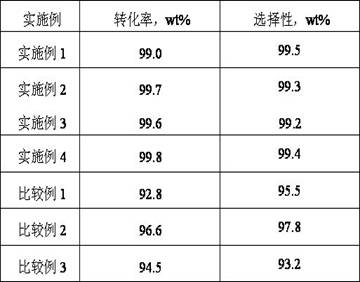

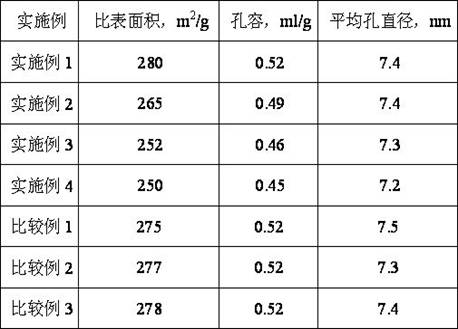

Heteropolyacid ammonium salt catalyst and preparation method thereof

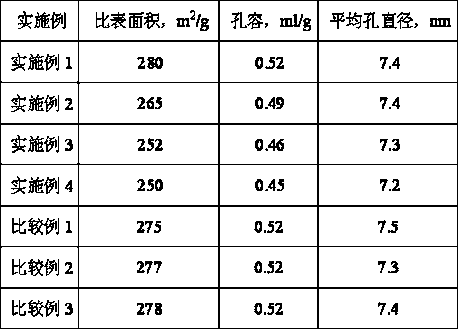

ActiveCN109926091AIncrease profitEnhanced Surface AcidityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationActive componentSilicon dioxide

The invention discloses a heteropolyacid ammonium salt catalyst and a preparation method thereof, wherein the catalyst comprises an active component, an auxiliary agent and a carrier, the active component is a heteropolyacid ammonium salt, the auxiliary agent is phosphorus, and the carrier is an alumina and silica composite support. The preparation method comprises: preparing a catalyst precursor,modifying it, and finally supporting an active component. The catalyst of the invention has high reactivity and high selectivity, and is particularly suitable for the reactions for preparing ethyleneby using a low-concentration ethanol aqueous solution as a raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

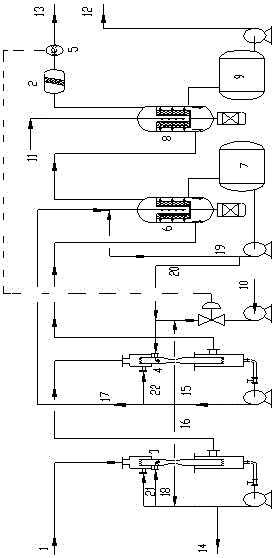

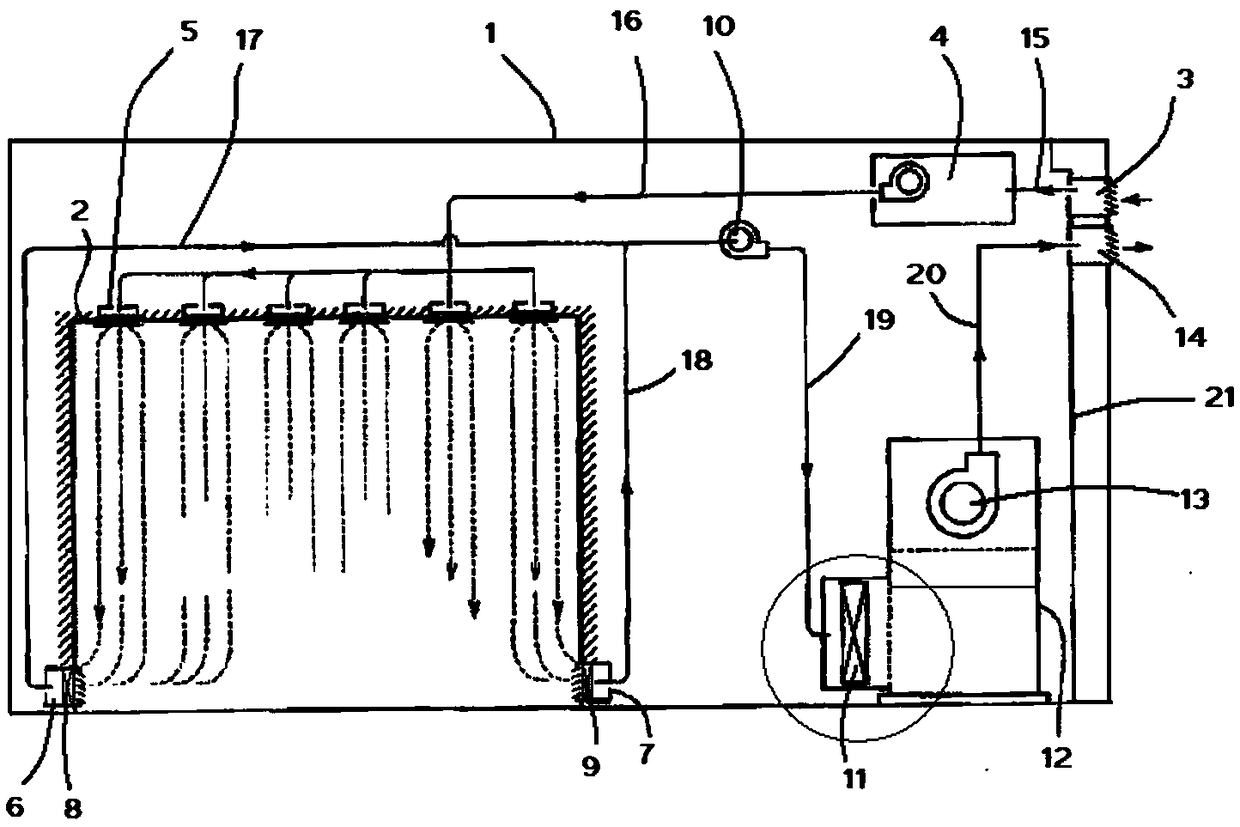

Novel acidic gas treating process and apparatus

ActiveCN104826464AIncreased depth of responseFully contactedDispersed particle separationPhysical chemistryPrecipitation

The invention provides a novel acidic gas treating process and apparatus. The acidic gas treating process employs a gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, the secondary liquid reaction product is used a tertiary reaction absorption liquid, and an MDEA solution is used as a fourth-stage reaction absorption liquid; thus, the purpose of replacement of CO2 with H2S is achieved, the generation amounts of Na2CO3 and NaHCO3 in a liquid phase product are reduced, precipitation of crystals is prevented, and long cycle operation of the apparatus is guaranteed. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants.

Owner:CHINA PETROLEUM & CHEM CORP +1

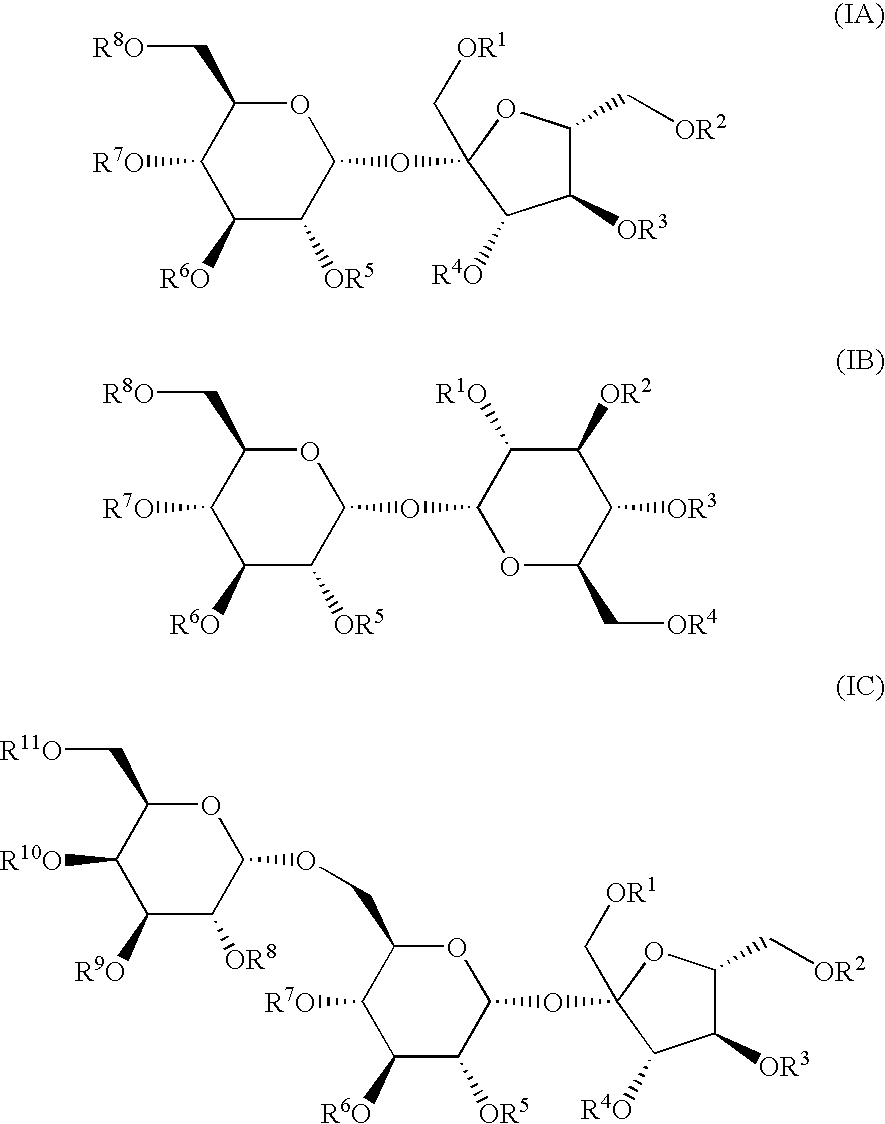

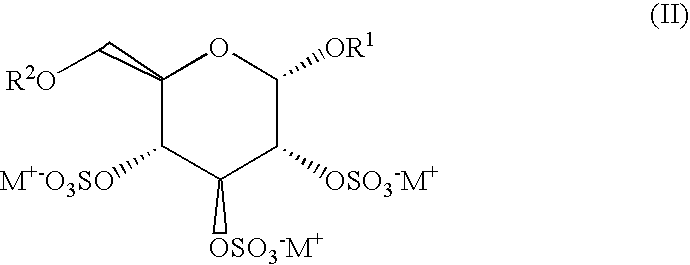

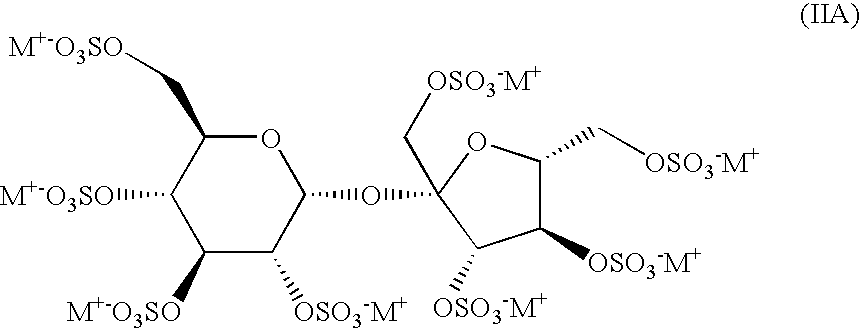

Sulfated oligosaccharides

InactiveUS20090215717A1Reduce overreactionSuppress growth factor-induced proliferation of smooth muscle cellsBiocideOrganic active ingredientsSulfated polysaccharidesMammal

The invention relates to sulfated oligosaccharides, more particularly to new pharmaceutical uses of sulfated oligosaccharides. The invention provides a method of preventing, treating or alleviating the symptoms of acute and chronic’, inflammatory disorders of the airways of mammals—including asthma and asthma-related pathologies. The invention further provides use of a sulfated oligosaccharide in the preparation of a medicament for the treatment of acute and chronic inflammatory disorders of the airways of mammals. The invention yet further provides use of a sulfated oligosaccharide to preventing, treating or alleviating the symptoms of acute and chronic inflammatory disorders of the airways of mammals—including asthma and asthma-related pathologies.

Owner:IVAX DRUG RES INST

Compound ambroxol hydrochloride composition and its preparation method

ActiveUS20140206710A1Increase secretionLow viscosityBiocidePharmaceutical non-active ingredientsActivated carbonMANNITOL/SORBITOL

A compound ambroxol hydrochloride composition and a preparation method therefor, which relate to the field of medicine. 0.1%-99.9% by mass of ambroxol hydrochloride and 99.9%-0.1% by mass of scopolamine serving as main ingredients and mannitol are added into water for injection; stir to dissolve, then adjusting to pH 5.0 by adding an NaOH solution; add 0.1% of activated carbon with stirring for 30 minutes; filter out the activated carbon, and then filtering the liquid with 0.45 μm and 0.22 μm microporous filter membranes; fill the filtered liquid into a large plate or a vial; send into a lyophilizer, cool to −40° C., and hold the temperature for 2 hours; warm to −5° C. to 0° C. slowly to lyophilize the liquid, heat to 35° C., and hold the temperature for 3 hours; take out of the lyophilizer after lyophilizing to obtain a lyophilized powder injection containing ambroxol hydrochloride and scopolamine; crush the lyophilized powder injection under a sterile conditions, and sieve with a 180-mesh sieve to obtain sterile lyophilized powder containing ambroxol hydrochloride and scopolamine; and prepare various dosage forms by using the lyophilized powder as a raw material.

Owner:HAINAN WEI KANG PHARMA QIANSHAN

A kind of face cream with anti-aging effect and preparation method thereof

ActiveCN104434747BMild in natureGood at scavenging free radicalsCosmetic preparationsToilet preparationsIrritationTremella

The invention discloses face cream with an anti-aging function and a preparation method of the face cream. The face cream disclosed by the invention contains hydrolyzed cod fish skin collagen, carboxymethyl chitosan, a tremella extract, oat-beta glucan and a composite plant anti-aging agent. The face cream with the anti-aging function disclosed by the invention is mild in property, natural and free of irritation and has a relatively good function of scavenging free radicals. By comprehensively applying various anti-aging policies, the face cream not only can be used as a skin care article for delaying senescence after aging, but also can be used as a daily skin care product for preventing aging. The face cream is obvious in anti-aging effect.

Owner:金日制药(中国)有限公司

Ambroxol hydrochloride composition and its preparation method

ActiveUS9000004B2Strong synergy effectQuick effectBiocidePharmaceutical non-active ingredientsActivated carbonMANNITOL/SORBITOL

An ambroxol hydrochloride composition and a preparation method therefor. 0.1%-99.9% by mass of ambroxol hydrochloride and 99.9%-0.1% by mass of scopolamine serving as main ingredients and mannitol are added into water for injection; dissolve, then adjust to pH 5.0; add 0.1% of activated carbon with stirring; filter out the activated carbon, and then filter the liquid; send into a lyophilizer, cool to −40° C., and hold the temperature for 2 hours; warm to −5° C. to 0° C. slowly to lyophilize the liquid, heat to 35° C., and hold the temperature for 3 hours; take out of the lyophilizer to obtain a lyophilized powder injection containing ambroxol hydrochloride and scopolamine; crush the lyophilized powder injection under sterile conditions, and sieve to obtain sterile lyophilized powder containing ambroxol hydrochloride and scopolamine; and prepare various dosage forms by using the lyophilized powder as a raw material.

Owner:HAINAN WEI KANG PHARMA QIANSHAN

A kind of heteropolyacid ammonium salt catalyst and preparation method thereof

ActiveCN109926091BIncrease profitEnhanced Surface AcidityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPtru catalystHeteropoly acid

The invention discloses a heteropolyacid ammonium salt catalyst and a preparation method thereof. The catalyst comprises an active component, an auxiliary agent and a carrier, the active component is a heteropolyacid ammonium salt, the auxiliary agent is phosphorus, and the carrier is alumina and Silica composite carrier. The preparation method of the heteropolyacid ammonium salt catalyst is as follows: firstly preparing a catalyst precursor, then modifying it, and finally loading active components. The catalyst of the invention has high reactivity and selectivity, and is especially suitable for the reaction of dehydration to ethylene with low-concentration ethanol aqueous solution as raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

A new type of acid gas treatment process method and device

ActiveCN104826464BIncreased depth of responseFully contactedDispersed particle separationFluid phasePhysical chemistry

The invention provides a novel acidic gas treating process and apparatus. The acidic gas treating process employs a gas-liquid two-phase countercurrent absorption reaction and uses a NaOH solution as an absorption liquid to treat acidic gas so as to produce NaHS. According to the process, a primary liquid reaction product and a secondary liquid reaction product are cyclically used, the secondary liquid reaction product is used a tertiary reaction absorption liquid, and an MDEA solution is used as a fourth-stage reaction absorption liquid; thus, the purpose of replacement of CO2 with H2S is achieved, the generation amounts of Na2CO3 and NaHCO3 in a liquid phase product are reduced, precipitation of crystals is prevented, and long cycle operation of the apparatus is guaranteed. The acidic gas treating process provided by the invention is simple and can achieve the dual objectives of purification of acidic gas and reclamation of pollutants.

Owner:CHINA PETROLEUM & CHEM CORP +1

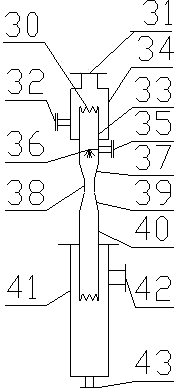

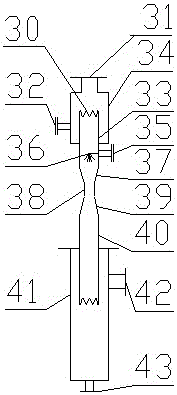

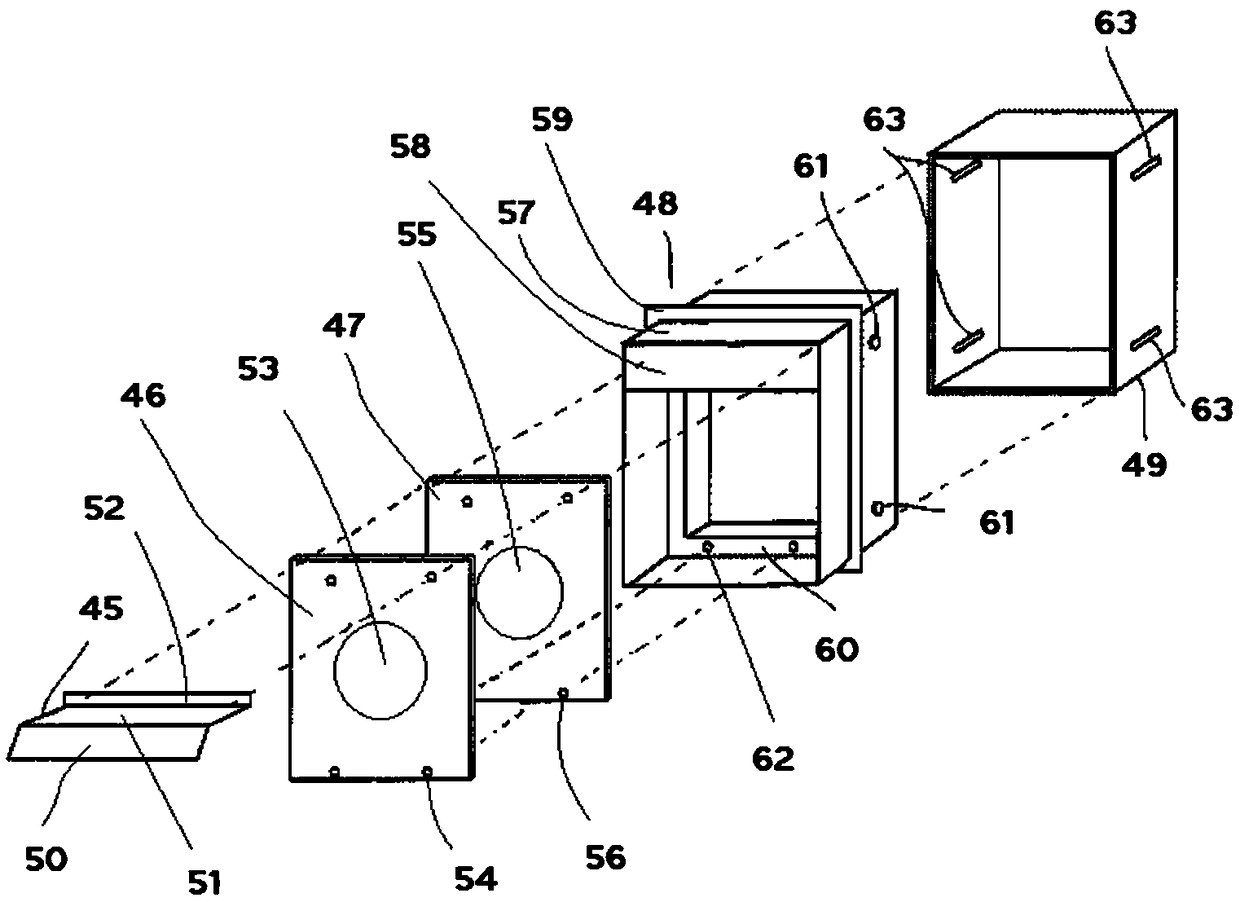

A portable vaccine injection device

InactiveCN110801306BReduce overreactionAvoid direct contactAutomatic syringesIntravenous devicesDomestic birdPhysical therapy

Owner:成冲 +1

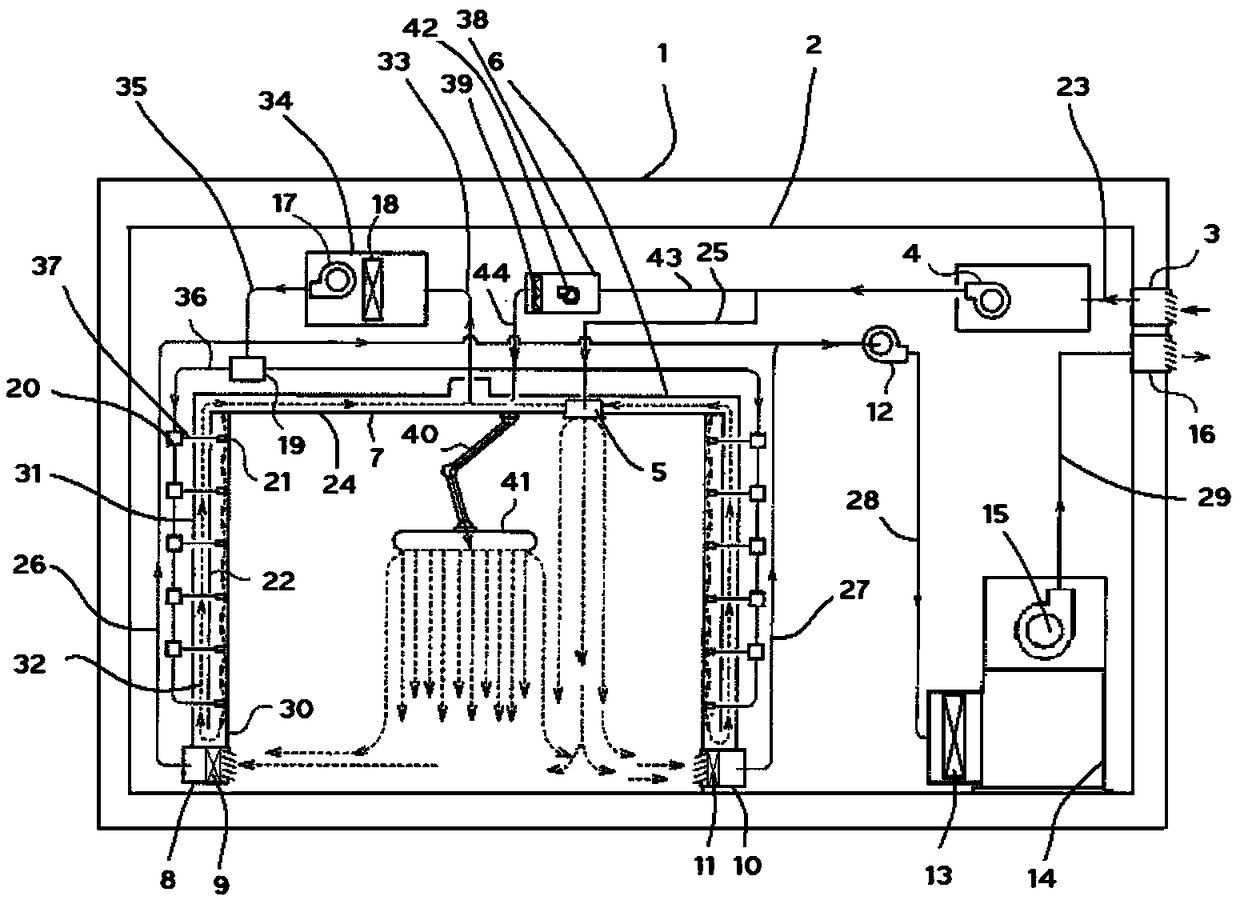

Agricultural livestock transport container with telescopic exhaust device

InactiveCN108633756AReduce overreactionGuaranteed supplyLarge containersAnimal housingEngineeringCargo container

The invention relates to an agricultural livestock transport container with a telescopic exhaust device. The container comprises a telescopic air-supplementing and humidifying component; wherein the telescopic air-supplementing and humidifying component comprises an air-supplementing and humidifying component mounting shell, a humidifier, a foldable ventilation crank arm, a telescopic humidifyingdistributor and a fifth fan. Under the condition that the structure of an existing freight container is less changed, the container provided by the invention can improve the survival rate of living livestock in transportation, in particular the survival rate of young livestock, reduce the overreaction of the livestock, simultaneously reduce the cost as much as possible, and meet the requirements of greenness and environmental protection.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

Heteropolyacid ammonium salt catalyst and its preparation method

ActiveCN109926092BIncrease profitEnhanced Surface AcidityOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound dehydrationPtru catalystHeteropoly acid

The invention discloses a heteropolyacid ammonium salt catalyst and a preparation method thereof. The catalyst comprises an active component, an auxiliary agent and a carrier. The active component is heteropolyacid ammonium salt, the auxiliary agent is Fe, and the carrier is a composite carrier of alumina and silicon dioxide. The catalyst of the invention has high low-temperature activity and selectivity, and is especially suitable for the reaction of dehydrating methanol raw materials with high water content to produce dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

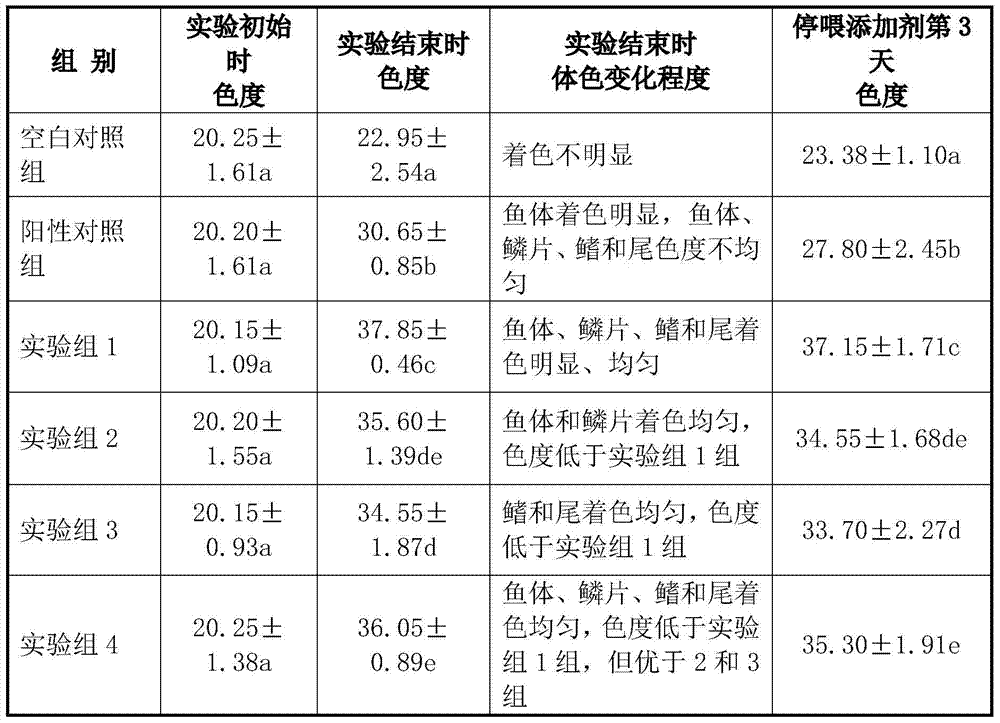

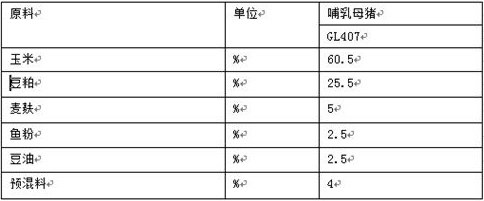

Blood parrot triple red-enhancing feed additive and its application

ActiveCN104686805BObvious reddening effectBright red uniform colorAnimal feeding stuffAccessory food factorsAnimal scienceFood grade

Owner:南京一品红水族用品科技发展有限公司

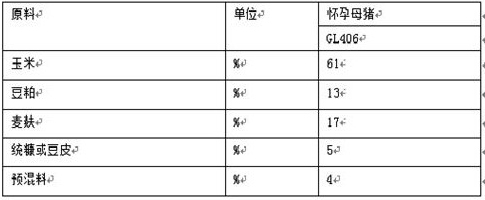

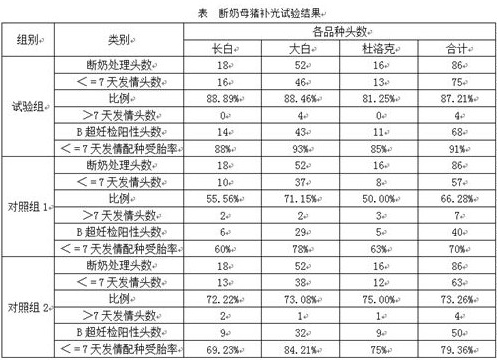

A method to increase the estrus rate of weaned sows

ActiveCN109042514BShorten heating timeReasonable mix of ingredientsFood processingAnimal feeding stuffMedicineZoology

The invention relates to the technical field of weaning sow feeding, in particular to a method for increasing the estrus rate of weaning sows. The method of the present invention mainly comprises: a. weaning of sows: weaning of sows is weaned according to the age of suckling piglets and enters the positioning bar for weaning, and the age of weaning is 21-28 days; b. weaning management: feeding sows feed on the day of weaning , add sugar every day, and set up a lighting supplementary system in the weaning school building to supplement the light; c. Trial mating: use different boars to trial mating every day, mating sows after estrus, and feeding gestational feed on the day after mating; d. Weaning sows Sows that have not been in estrus for ≥8 days are reared in groups from the positioning pen to the weaning pen. The invention provides a method for increasing the estrus rate of weaned sows, which is designed according to the body changes of the weaned sows, effectively shortens the estrus time of the weaned sows, improves the physique of the weaned sows, and increases the estrus rate and pregnancy success rate within 7 days.

Owner:广西农垦永新畜牧集团西江有限公司

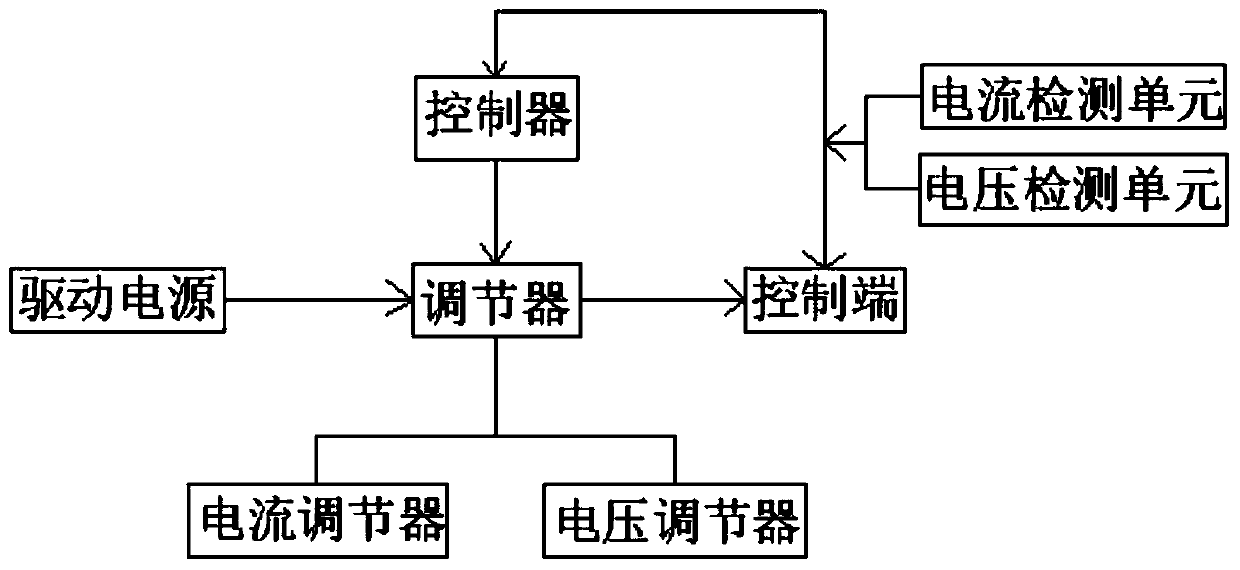

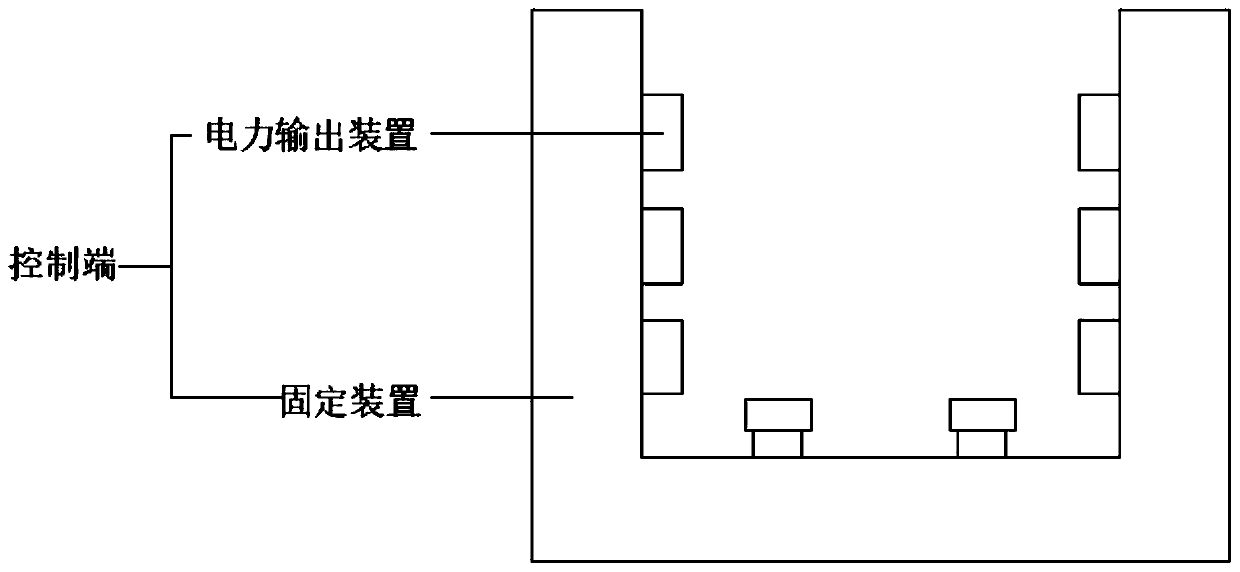

Power system capable of adjusting electric shock data

PendingCN111525776AAffect qualityReduce overreactionElectric current slaughtering/stunningElectric powerElectric power systemEngineering

The invention belongs to the technical field of electric power, and specifically relates to a power system capable of adjusting electric shock data. The system comprises a driving power supply, a regulator, a controller, a control end and a detection system. The output of the driving power supply is connected with the regulator. The output of the controller is connected with the regulator. The output of the regulator is connected with the control end. The output of the detection system is connected with the control end and the controller. The detection system comprises a current detection unitand a voltage detection unit. The regulator comprises a current regulator and a voltage regulator, a digital control technology is adopted, and the current and the voltage can be regulated to slowlyrise by setting, so that a pig is unconsciously subjected to corona, the overshoot reaction is reduced, the overshoot phenomenon is reduced, and the bone fracture rate and the white muscle rate are reduced.

Owner:上海航裕电源科技有限公司

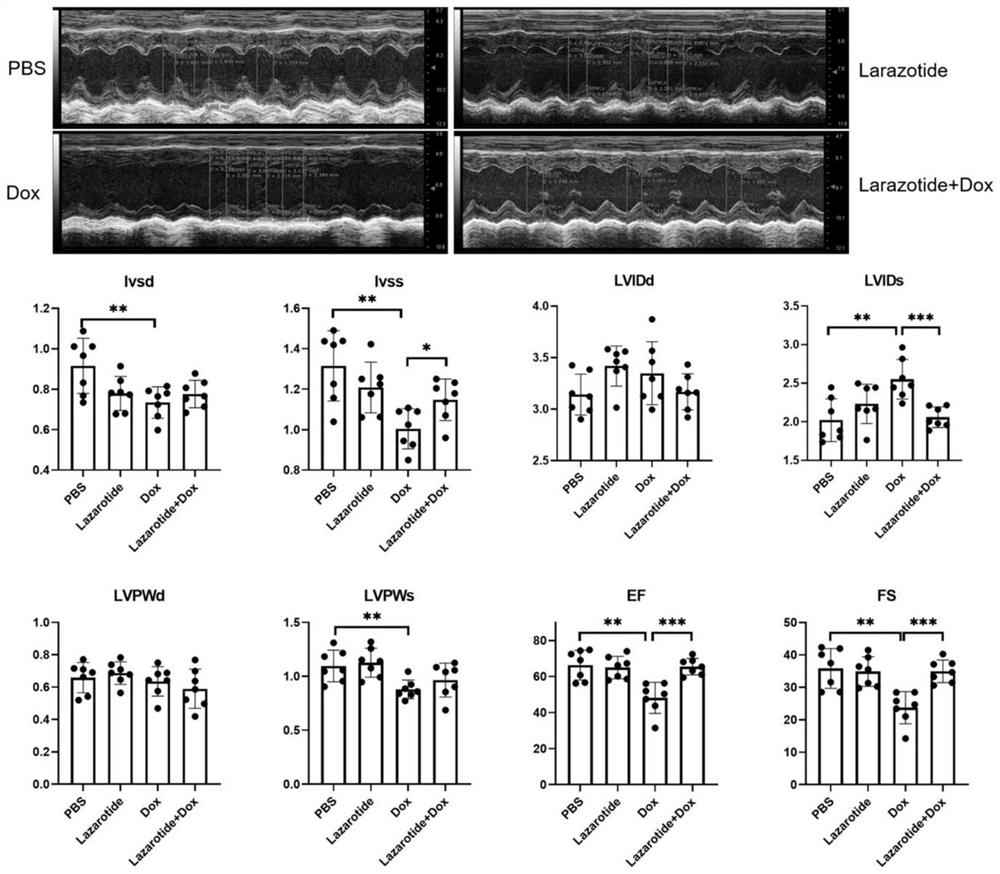

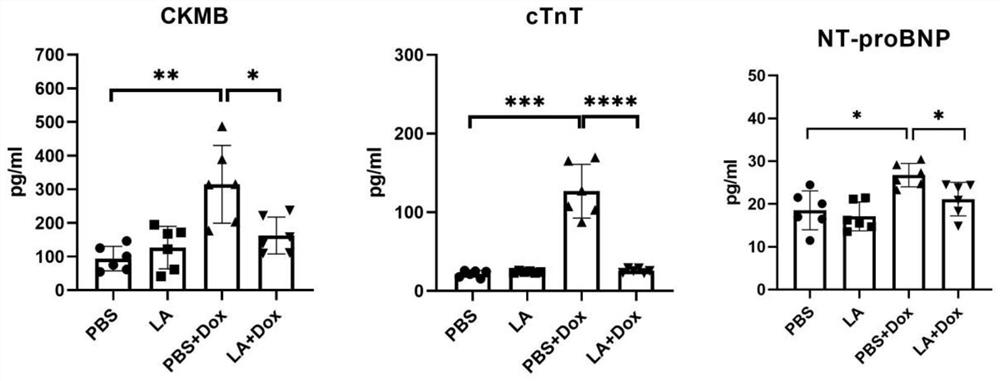

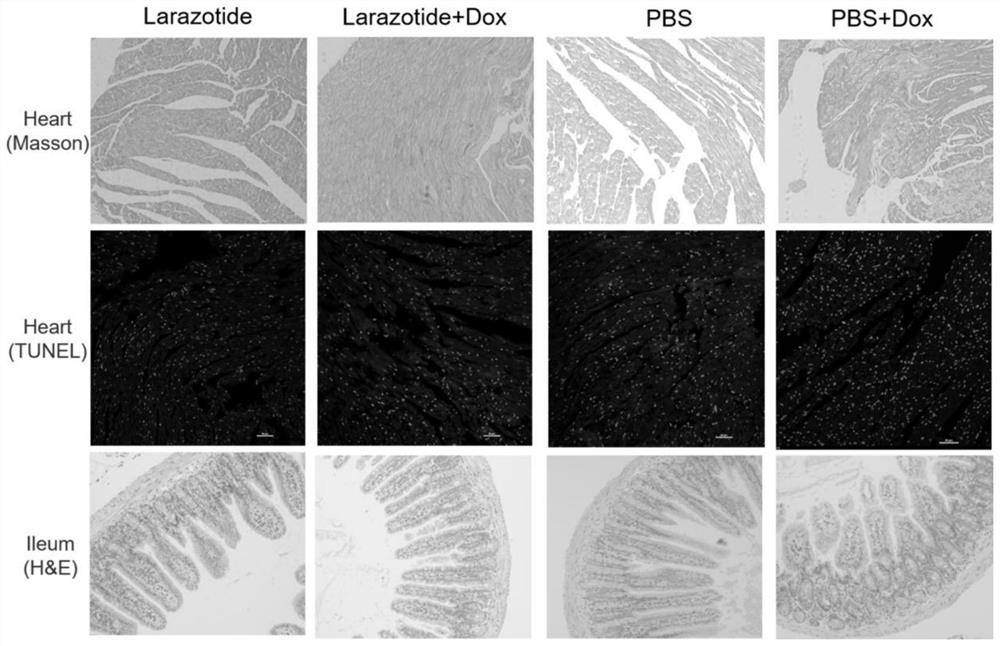

Application of laurazolette polypeptide in preparation of medicine for relieving doxorubicin cardiotoxicity

PendingCN114832088APrevent toxicityProtection from damagePeptide/protein ingredientsDigestive systemSide effectLeft ventricular size

The invention discloses an application of a larazotide in preparation of a medicine for relieving doxorubicin cardiotoxicity, and relates to a preparation method of a drug for relieving doxorubicin cardiotoxicity. In-vivo experiment results show that the Larizotide can effectively relieve the toxic effect of the chemotherapeutic drug adriamycin on the heart, and by improving the homeostasis of immune cells of the body and the heart, the cell apoptosis of myocardial tissue is relieved, the increase of myocardial zymogram is relieved, and the left ventricular diastolic ability and the cardiac ejection fraction are enhanced, so that the toxic and side effects of the chemotherapeutic drug adriamycin are reduced, and the curative effect of the chemotherapeutic drug adriamycin is improved. Meanwhile, the intestinal barrier function injury caused by adriamycin chemotherapy is also improved. The traditional Chinese medicine composition overcomes the defects of current Dox clinical medication limitation and existing chemotherapy heart protection medicines, and solves the problem of prevention and treatment of cardiotoxicity and intestinal side effects induced in Dox chemotherapy.

Owner:李臻

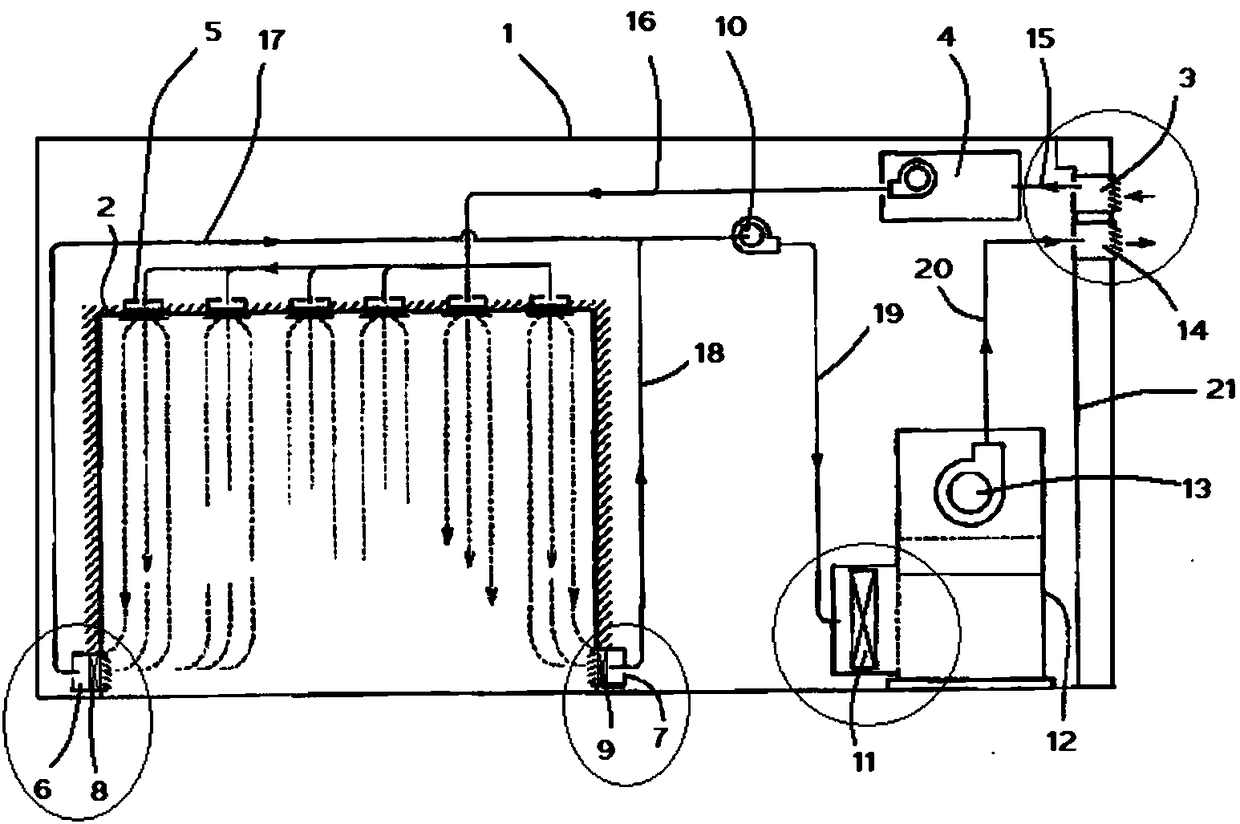

Living livestock transportation container with air inlet and outlet pipeline integration module

InactiveCN108482884AImprove survival rateReduce overreactionDispersed particle filtrationLarge containersEngineeringCargo container

The invention discloses a living livestock transportation container with an air inlet and outlet pipeline integration module. The container comprises the air inlet and outlet pipeline integration module. According to the container, under the condition that the structure of the existing cargo container is slightly changed, the survival rate of living livestock transportation is improved, the over excitation reaction of the livestock is reduced, the looseness of a pipeline in the transportation process can be prevented, meanwhile, modification and installation of the container are facilitated, the cost is reduced as much as possible, and the green and environment-friendly requirement is taken into consideration.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

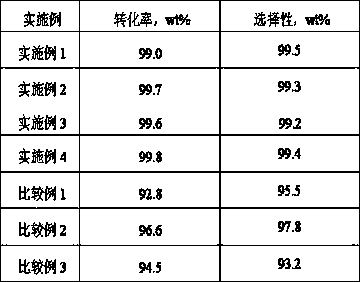

A kind of method of producing 5-hydroxymethylfurfural

ActiveCN109439706BReduce energy consumptionPromote hydrolysis reactionXylose productionFermentationChemical industryFuraldehyde

The invention belongs to the field of chemical industry, in particular to a method for producing 5-hydroxymethyl furfural. The method comprises the following steps: 1) pulverizing the raw materials, soaking in dilute sulfuric acid, and then squeezing dry; 2) steam blasting the squeezed-dried material; 3) water-extracting the blasted material and squeezing it dry; 4. ) The water extract is filtered, purified and concentrated to obtain xylose liquid; 5) Enzyme is added to the bamboo slag for enzymolysis, and then filtered; 6) The obtained glucose enzymolysis solution is separated from acetic acid, lignin impurities to obtain glucose solution; 7) the glucose solution is mixed with hydrochloric acid and sec-octanol in the emulsification pump; it enters the impact flow reactor and the static mixer coupling device for reaction, etc. The invention greatly improves the yield and production efficiency of preparing 5-hydroxymethylfurfural from glucose, saves the extraction solvent, reduces the production cost and equipment investment, does not discharge waste liquid in the production process, and is a green environmental protection process method.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

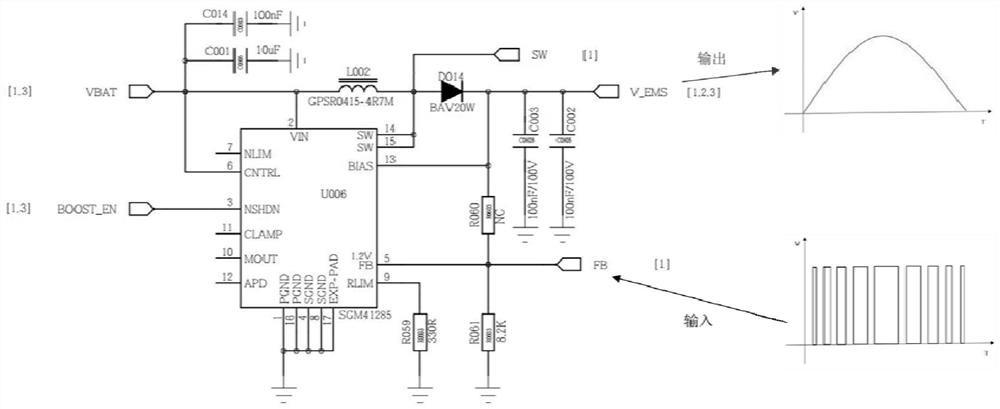

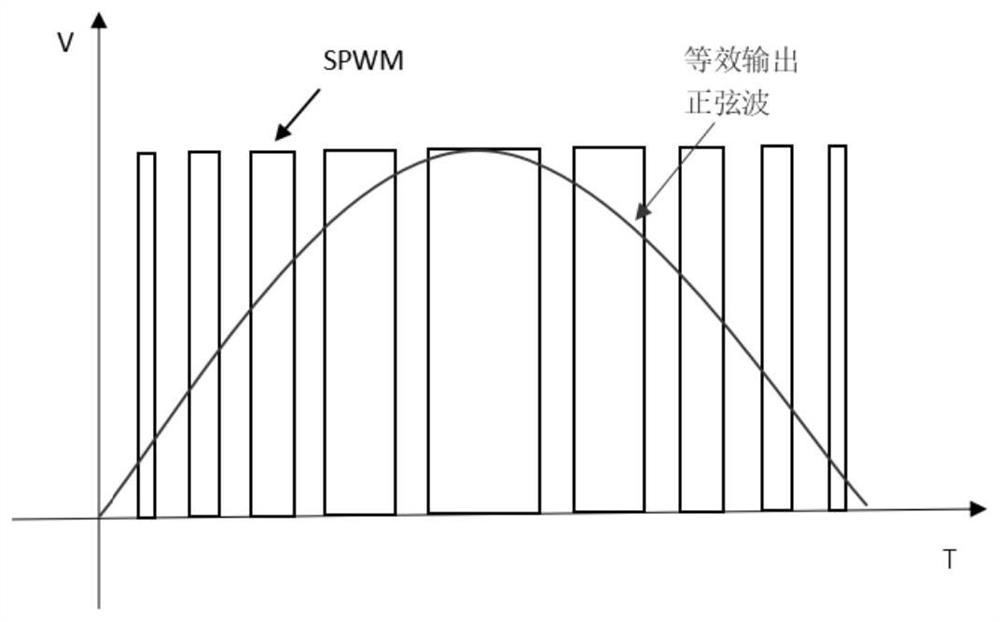

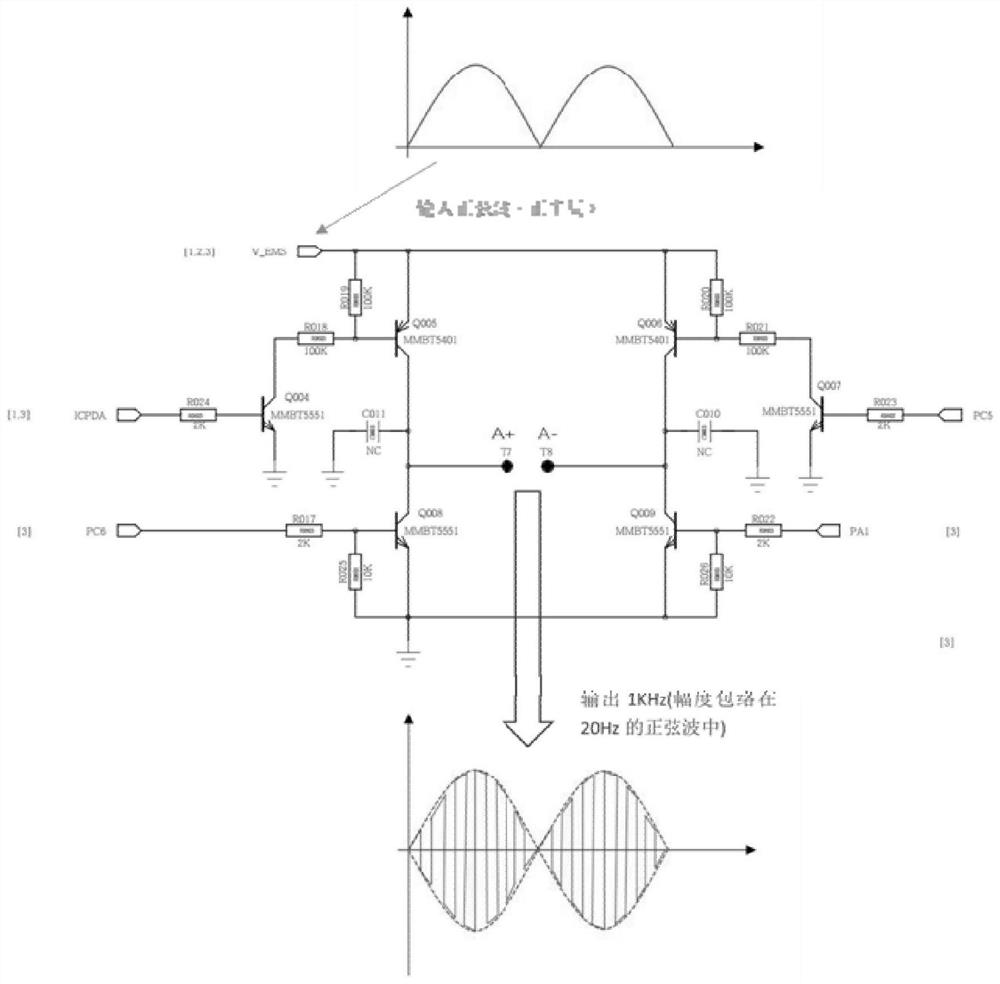

Multifunctional body contouring system for generating sinusoidal vibrations

ActiveCN111225713BSoftReduce overreactionElectrotherapyArtificial respirationIntermediate frequencyMassage

A multi-functional body shaping instrument system for generating sine wave vibrations to generate sine waves to act on the skin to achieve massage, fitness, weight loss and other effects. Compared with square wave output, the sine wave effect makes the skin feel softer and has the feeling of massage. Make the skin more comfortable; sine wave AC output, when the electrode is switched, the voltage is transitioned from small to large, reducing muscle overreaction; only the continuous sine wave of the positive half cycle is a low-frequency wave, acting on the superficial skin; m sine wave is an intermediate frequency Waves can penetrate the surface layer and enter the deep layer; envelope waves can stimulate muscle excitement from the outside to the inside, and truly exercise muscles in all directions.

Owner:SHENZHEN GUIZHIZUSHENG TECH CO LTD

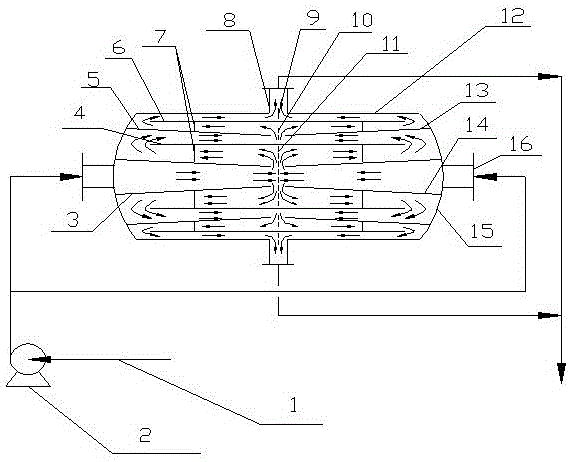

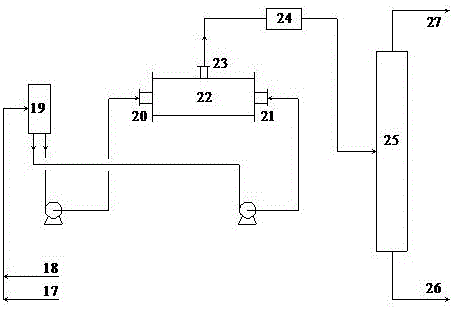

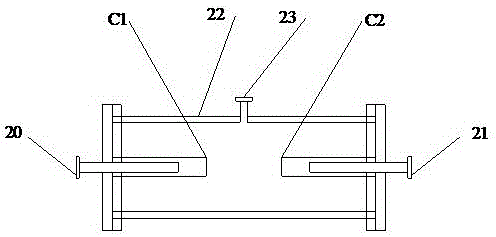

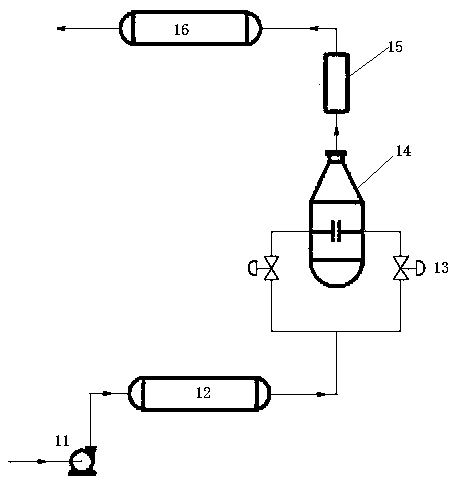

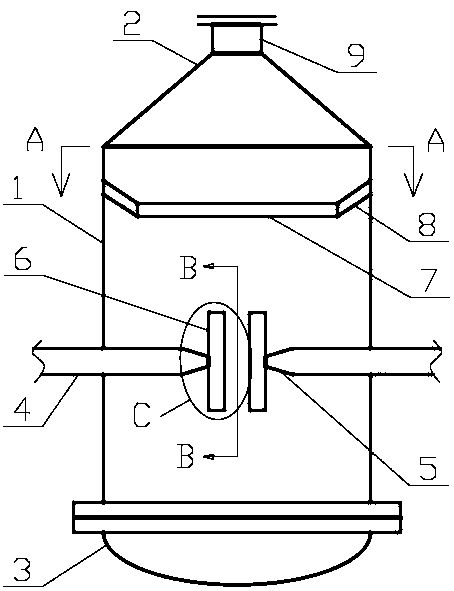

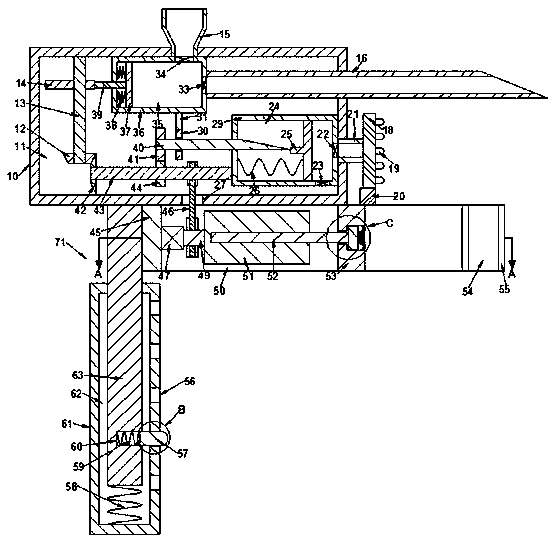

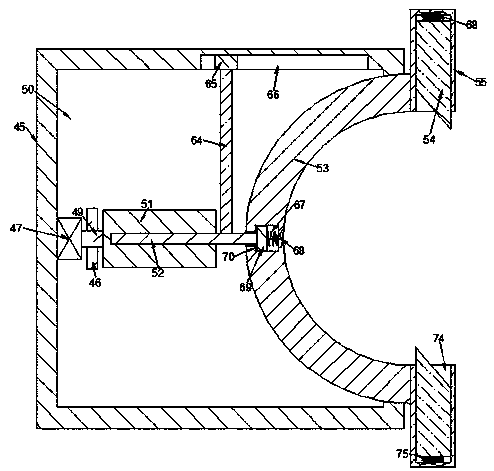

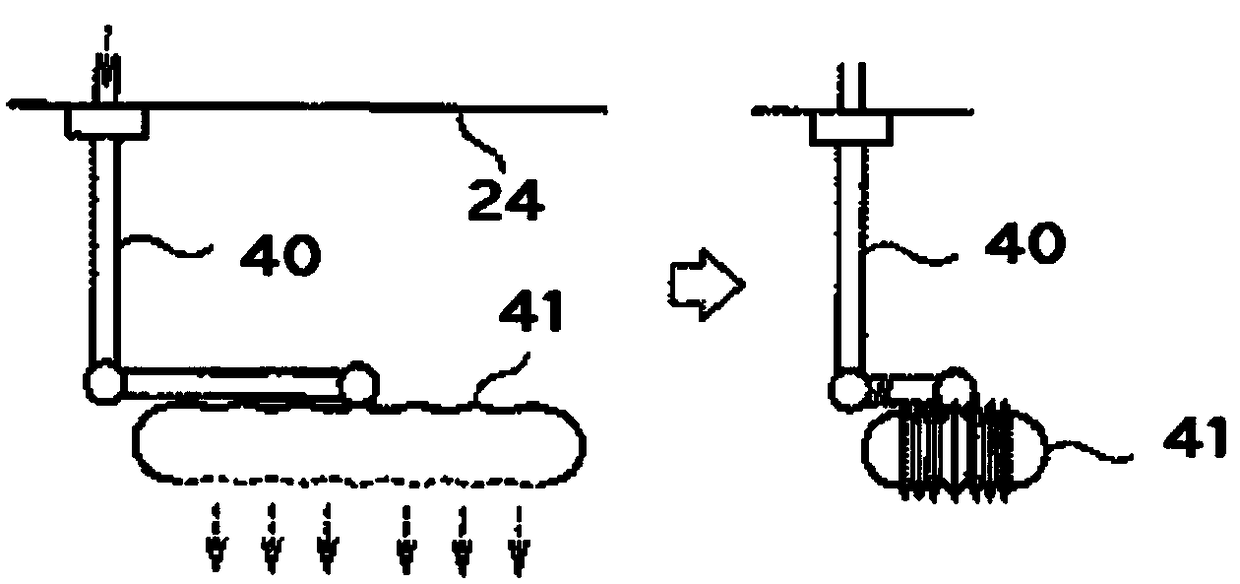

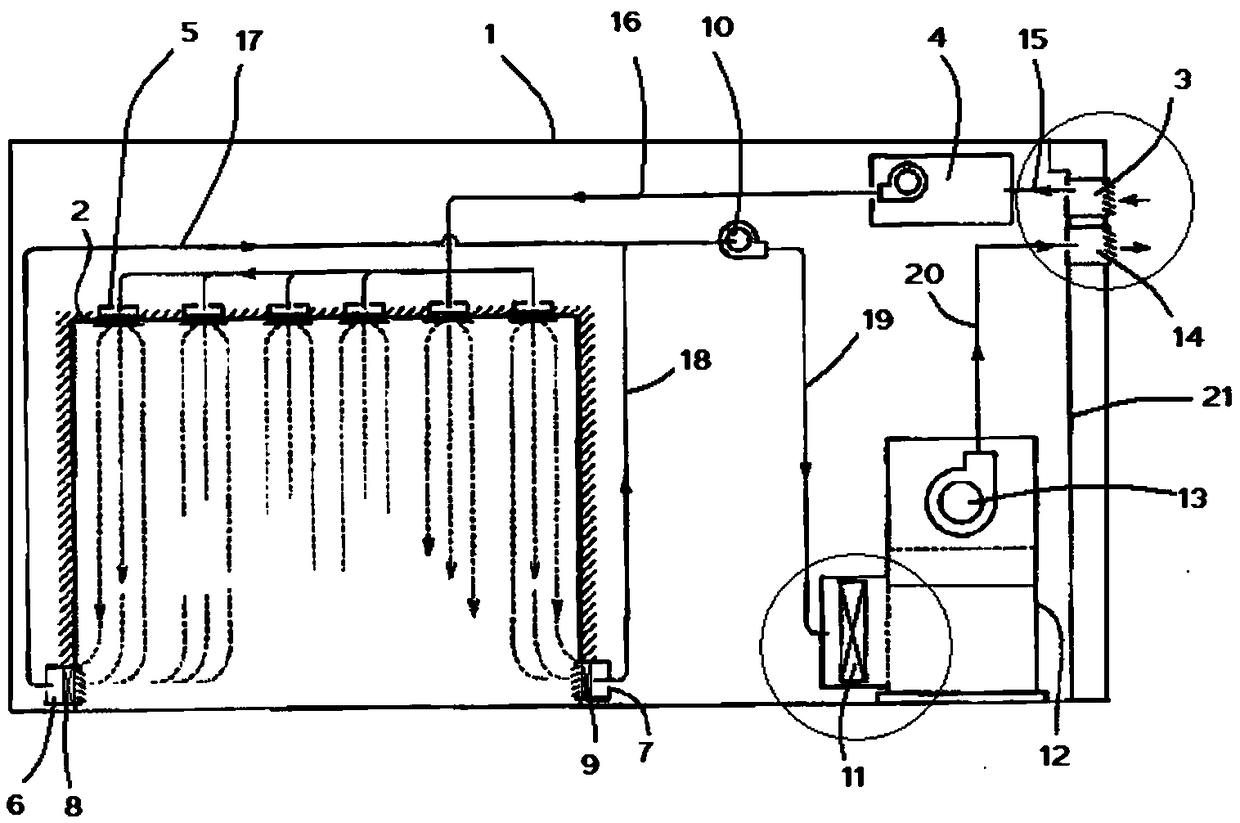

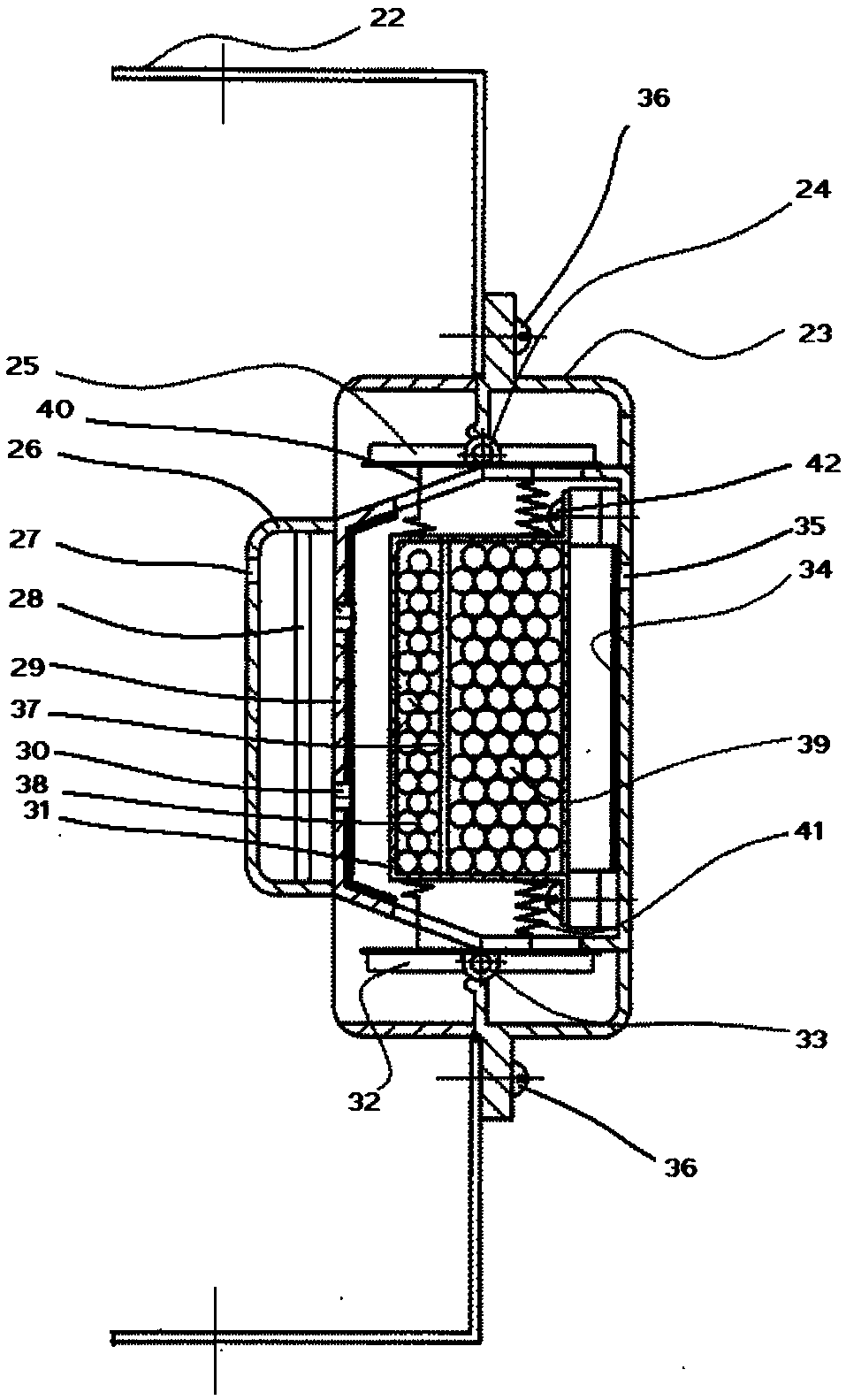

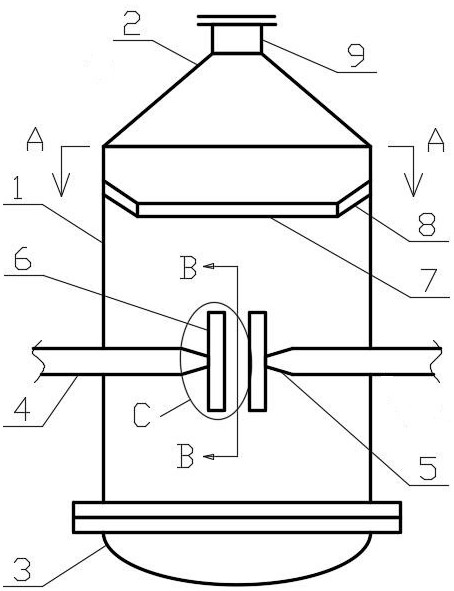

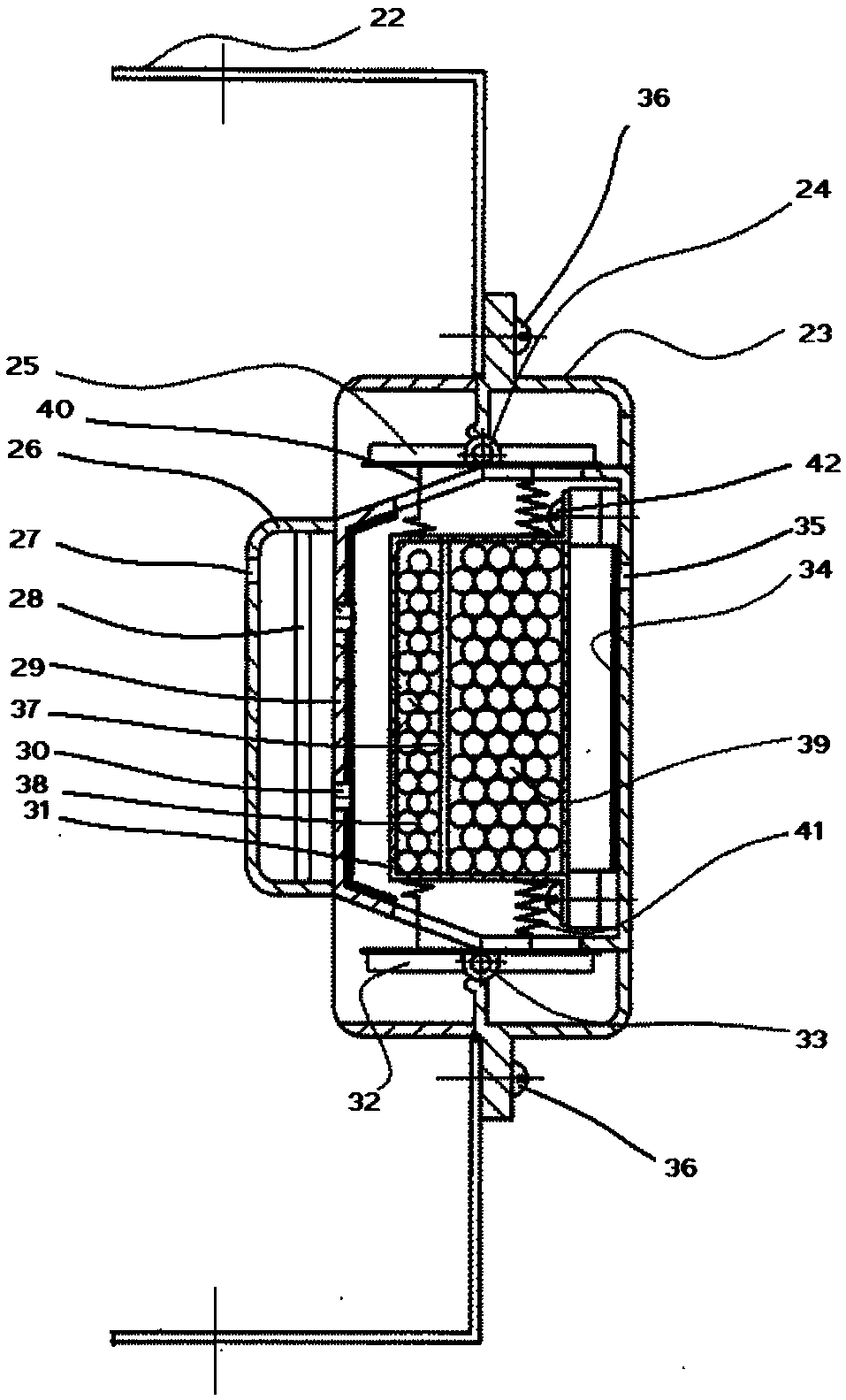

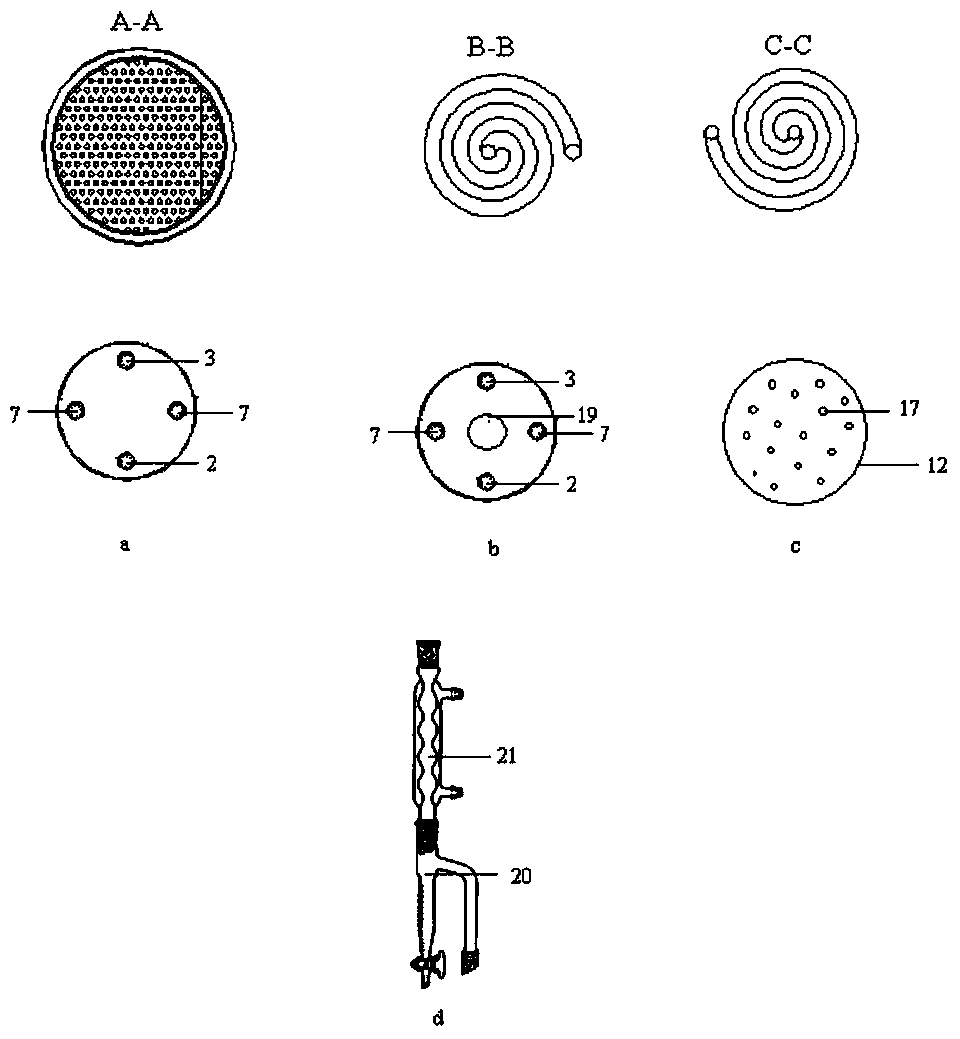

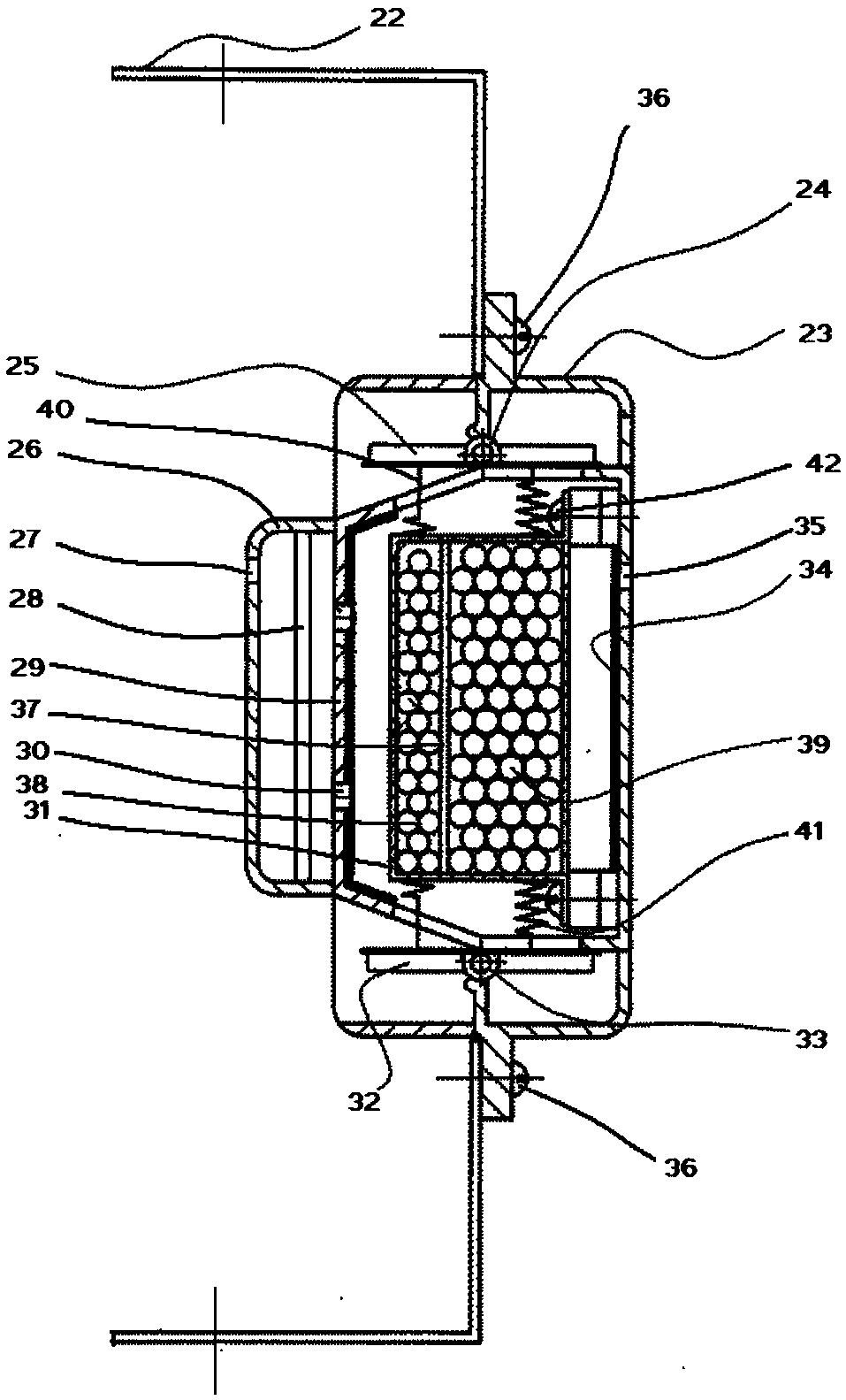

A liquid impinging-stream reactor

ActiveCN105749828AReduce volume utilizationIncrease the volume ratioLiquid-liquid reaction processesNuclear engineeringResidence time

An impinging-stream reactor used for liquid-liquid mixing is disclosed. The reactor comprises a reactor shell and draft tubes. The reactor shell comprises a cylinder and heads. Centers of the outsides of walls of two ends of the reactor shell are provided with two perpendicular opposite feeding pipes. The first draft tubes are formed through two circular truncated cone shells disposed in an opposite manner, axes of the shells and the reactor coincide, and a thicker end of each of the draft tubes is connected to the corresponding feeding pipe; the second draft tube is disposed outside the first draft tubes, is cylindric, and is connected to the heads or the first draft tubes, and the axis of the second draft tube and the axis of the reactor coincide; and so on, the reactor can include a plurality of groups of draft tubes. The reactor achieves a plurality of times of liquid impinging, provides sufficient residence time for materials, achieves stepped reactions, reaches the target conversion ratio through designing flowing paths and a liquid flow rate, and overcomes the disadvantage that an impinging-stream reactor at present cannot achieve a high conversion ration through a single reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

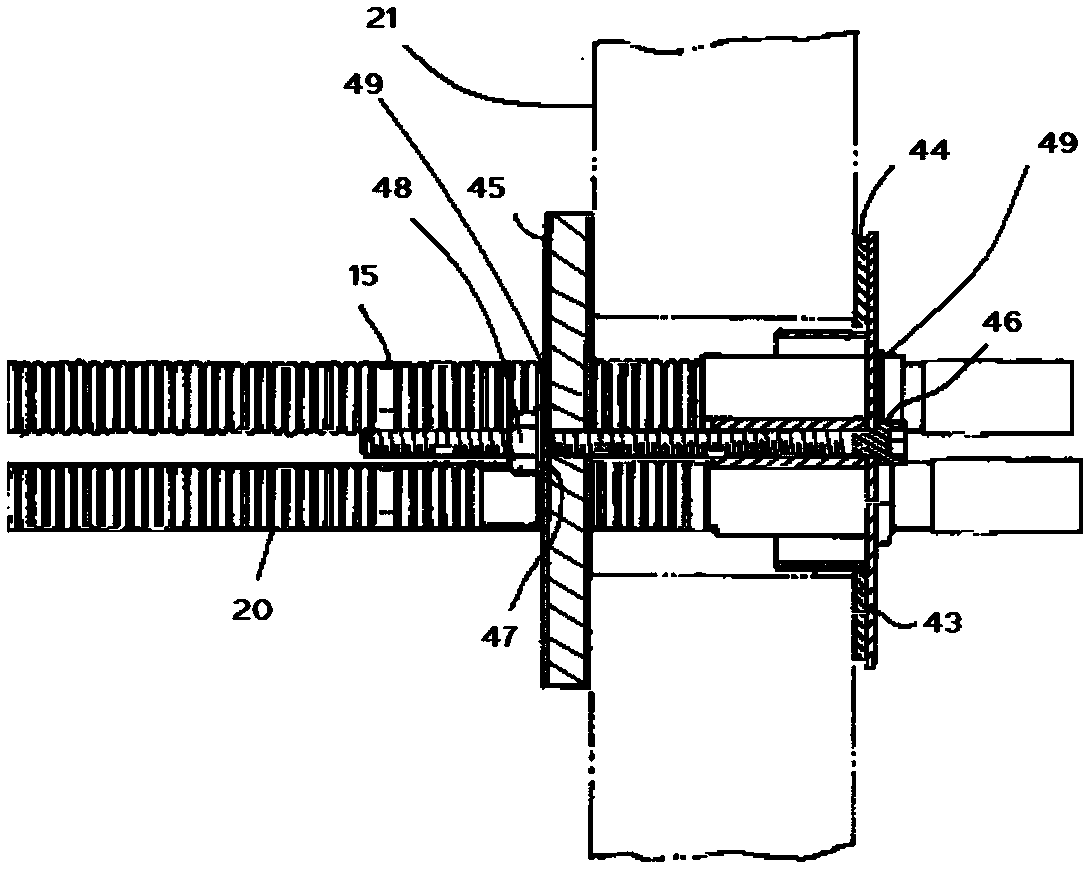

Inflating valve suitable for new energy automobile and production process of inflating valve

ActiveCN113464701AInhibition of thermo-oxidative decompositionImprove anti-oxidation and anti-aging performanceGroup 5/15 element organic compoundsAerating valvesRubber materialVulcanization

The invention discloses a production process of an inflating valve suitable for a new energy automobile. The production process comprises the following steps of I, pretreatment of the surface of the inflating valve: firstly, preparing a mixed acid solution, and adding zinc oxide into the mixed acid solution; adding a metal nozzle body into the mixed acid solution to be washed, and removing an oxide layer on the surface of the metal nozzle body; after washing, drying in a drying oven at 40-55 DEG C till complete drying; and preparation of a rubber material: putting the raw materials in parts by weight into an internal mixer for weight pressing, carrying out weight lifting and cleaning, weight pressing, weight lifting and cleaning, discharging rubber when weight pressing is conducted to the temperature of 70-120 DEG C, carrying out roller passing for 2-7 times through an open mill, and carrying out cooling to obtain the rubber material; adding the rubber material into gasoline, stirring and mixing, dip-coating the metal nozzle body in the rubber material for 30 minutes, airing, and carrying out rubber coating and vulcanization on the dipped metal nozzle body, so as to prepare the inflating valve suitable for the new energy automobile. The rubber material of the inflating valve has the advantages of good adhesion and ageing resistance.

Owner:江阴市创新气门嘴有限公司

A high-efficiency and energy-saving xylene separation process

ActiveCN107519827BReduce volume utilizationExtended stayChemical/physical/physico-chemical nozzle-type rreactorsLiquid-liquid reaction processesXylyleneM-Xylene

The invention discloses a process for separation and preparation of high-purity m-xylene from C8 aromatic hydrocarbon. An impinging stream reactor particularly suitable for the process is adopted, fluids are mixed through multiple impinging, good micromixing effect is achieved, the mixed liquid is pushed flatly and flows outside an impinging zone, adequate retention time is provided for the material, a cascade reaction is realized, and the target conversion rate is achieved through design of runners and the liquid flow velocity. The method overcomes the shortcoming that an impinging stream reactor cannot achieve high conversion rate through a single reactor at present, simplifies the technological process, reduces production cost and equipment investment, and ensures long-term operation of equipment. The method has no discharge of waste liquids in the production process, and is a green and environmental-friendly technological method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Agricultural transportation container for living livestock

InactiveCN108482885AImprove survival rateReduce overreactionDispersed particle filtrationLarge containersLivestockEngineering

An agricultural transportation container for living livestock comprises an outer housing, an inner housing, a first air inlet, a first air inlet fan, an air inlet of the inner housing of the container, a first air outlet of the inner housing of the container, a second air outlet of the inner housing of the container, a filter of the air outlet of the inner housing of the container, a filter of thesecond air outlet of the inner housing of the container, a first air outlet fan of the container, a third filter of the container, a mounting assembly of the third filter of the container, a second air outlet fan of the container and a third air outlet of the container. With the adoption of the agricultural transportation container for the living livestock, the survive rate of the living livestock in transporting can be increased and the overreaction of the livestock can be reduced on the premise that an existing cargo container structure is changed a little; and meanwhile, the cost is decreased to the maximum; and the green and environmental protection requirements are met.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

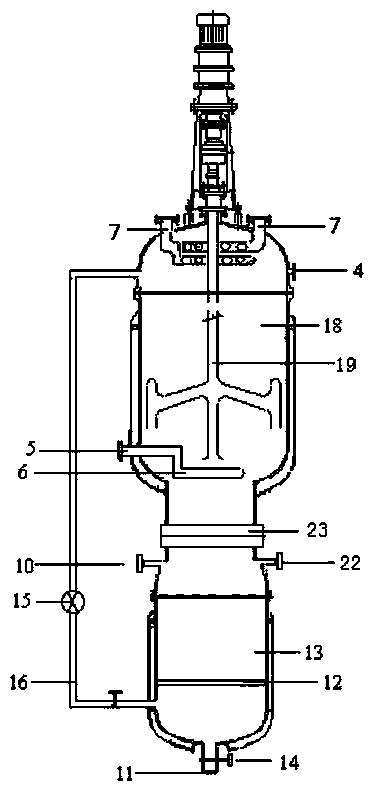

An Improved Reaction Separation Synchronous Reactor

ActiveCN105195064BSettling fastEasy to separateOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationMicropore FilterLiquid product

The invention discloses an improved reaction and separation synchronous reactor. The improved reaction and separation synchronous reactor comprises a bubble gravity reaction tower or stirring reaction tower and a constant-temperature settling tower, and is mainly characterized in that the bubble gravity reaction tower or stirring reaction tower is connected with the constant-temperature settling tower through a flange, a micropore filter plate allowing liquid to pass through is arranged in the constant-temperature settling tower, and a circulating pipeline is arranged at the position, on the lower portion of the micropore filter plate, of the constant-temperature settling tower and connected with the upper portion of a reaction zone of the reaction tower. According to the improved multiphase reactor, overreaction of products in a reaction kettle can be reduced so as to obtain a product with higher purity, blockage of a connecting pipeline between the reaction kettle and the constant-temperature settling tower and the circulating pipeline can be prevented, and a liquid product and a solid product can be effectively separated in time on the premise of completing reaction. The improved multiphase reactor is especially suitable for reactions where the specific gravity of products is larger than that of reactants and the products are insoluble for one another and comprise solids.

Owner:YUANJIANG HUALONG CATALYST TECH

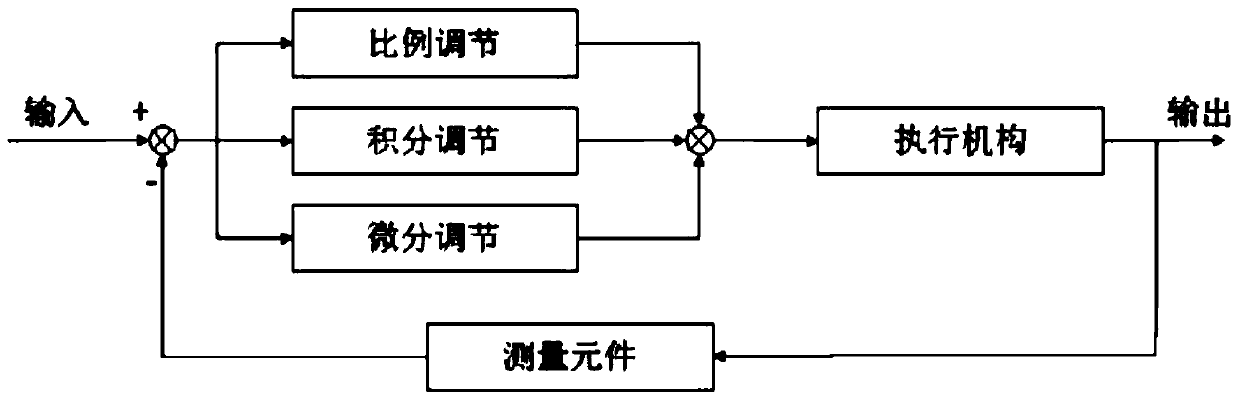

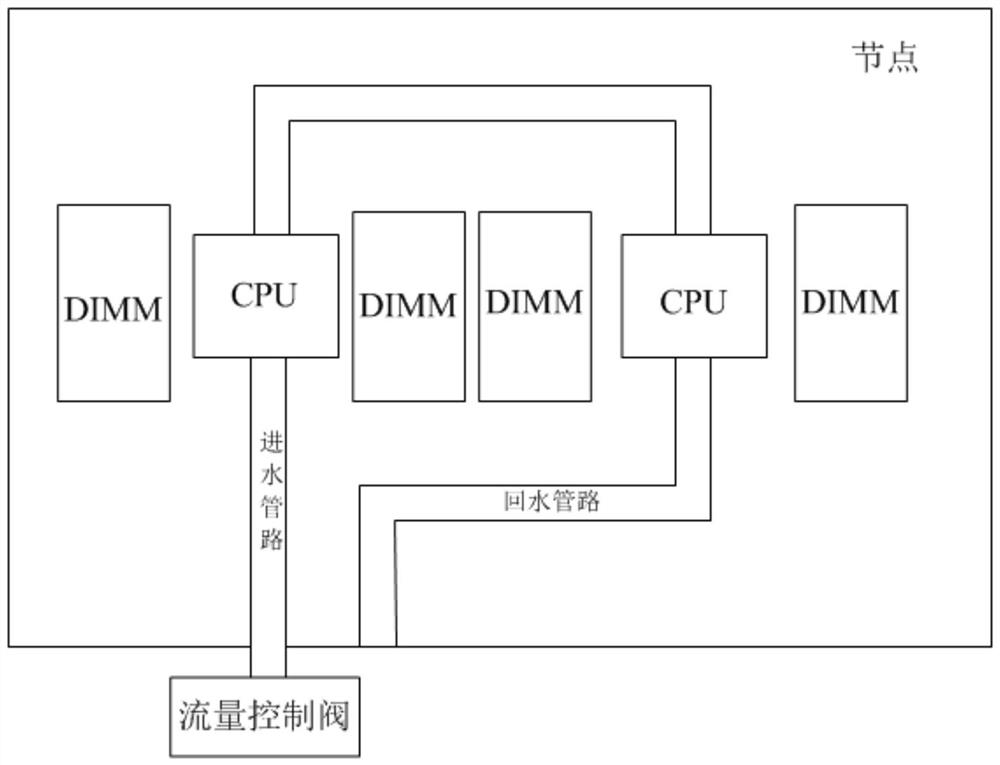

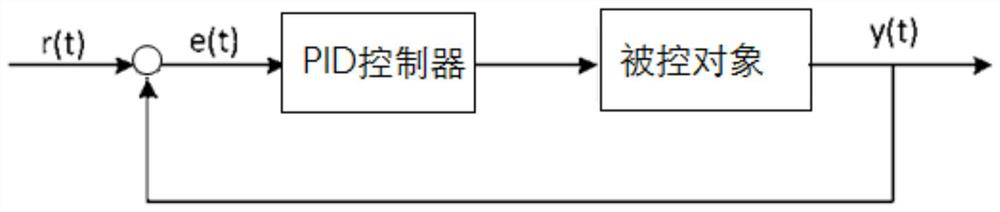

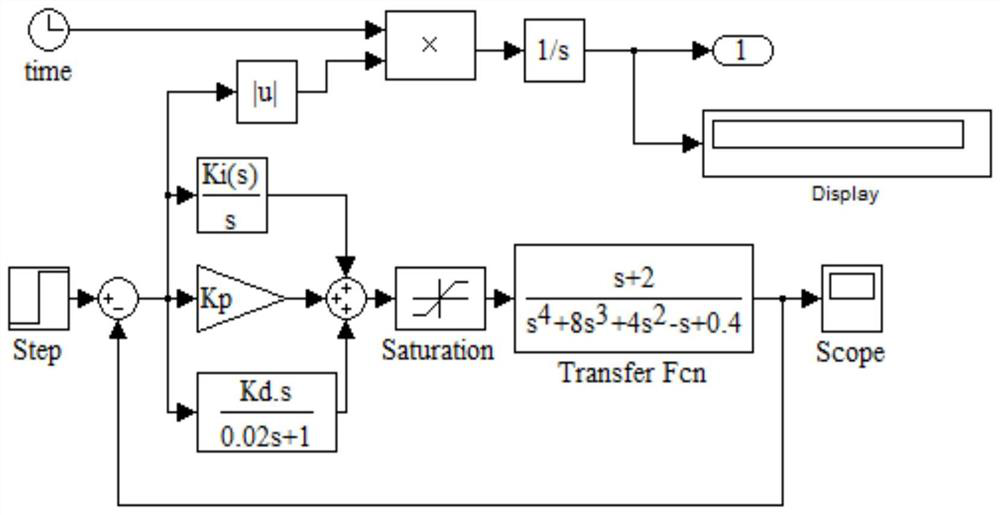

Cold plate liquid cooling intelligent heat dissipation regulation and control system, regulation and control optimization method and device

PendingCN114679885AReduce the PUE valueReduce overreactionModifications using gaseous coolantsDesign controlCold plate

The invention belongs to the technical field of intelligent heat dissipation regulation and control, and particularly provides a cold plate liquid cooling intelligent heat dissipation regulation and control system, regulation and control optimization method and device, and the method comprises the following steps: obtaining the utilization rate and the current temperature of a high-heat-flux component in a node; judging whether the utilization rate exceeds a set utilization rate threshold value or not; if not, reducing the rotating speed of the fan to the set minimum rotating speed value; if so, if the current temperature is greater than the target temperature, designing a PID controller according to the absolute value of the temperature variation; intelligent setting of PID parameters in the PID controller is carried out through a particle swarm algorithm; and the fan and the flow control valve are controlled through the set PID controller. Single-node flow and complete machine flow cooperatively control the flow speed, and the overreaction of the complete machine system flow is reduced. An artificial intelligence mode is adopted for control, and a set of flow and rotating speed control logic of the system is calculated to achieve the purpose of controlling power consumption to be optimal.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Livestock conveying container for agriculture

InactiveCN108502391AImprove survival rateReduce overreactionLiving organism packagingLarge containersLivestockAgriculture

A livestock conveying container for agriculture comprises a filtering core replacement assembly. According to the livestock conveying container, under the condition that an existing cargo container structure is changed a little, the survival rate of living livestock conveying is increased, the livestock overaction is reduced, loosening of a pipeline in the conveying process can be prevented, meanwhile the dismounting efficiency can be improved by adopting the filtering core replacement assembly of a clamping form, the cost is reduced as much as possible, and the environment-friendly requirement is taken into consideration.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com