A liquid impinging-stream reactor

A technology of impinging flow reactors and reactors, which is applied in the field of reactors to achieve the effects of saving reactor volume, reducing equipment investment, and reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

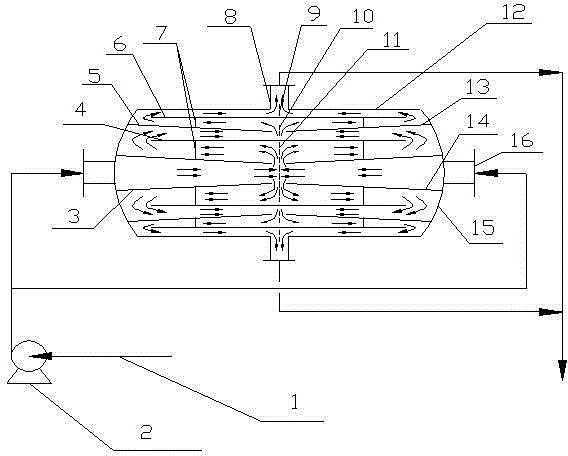

[0018] The liquid-phase impinging flow reactor of the present invention will be described in more detail below with reference to specific drawings.

[0019] Such as figure 1 As shown, a liquid-phase impingement flow reactor for liquid-liquid multi-effect mixing of the present invention includes two parts: a reactor shell and a draft tube. The reactor shell is composed of a cylinder 12 and a head 15 . Two facing feed pipes 16 are arranged at the central position of the outer wall of the reactor shell head 15, and the first guide tubes 3 and 14 are connected to the inside of the reactor shell with the feed tubes. The first guide tube 3 and 14 are respectively frustum-shaped shells, and the two frustum-shaped shells are placed facing each other, and the axis of the first guide tube (frustum-shaped shell) coincides with the axis of the reactor. The thick end of the frustum-shaped shell is connected to the feed pipe, and the liquid is accelerated and mixed at the outlet of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com