A high-efficiency and energy-saving xylene separation process

A m-xylene and process technology, which is applied in the field of separation and purification of aromatic xylene, can solve problems such as unsatisfactory residence time, achieve the effects of saving reactor volume, long material residence time, and eliminating excessive reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

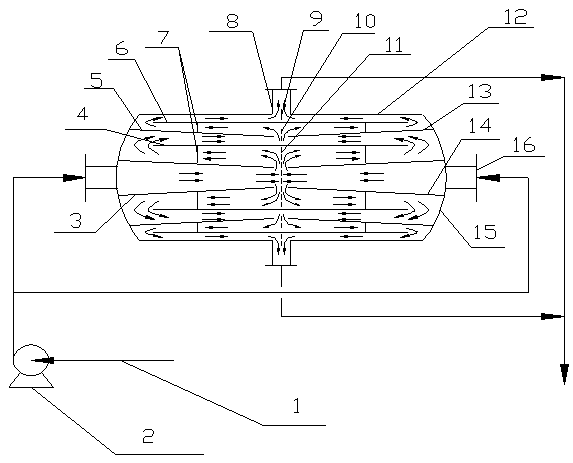

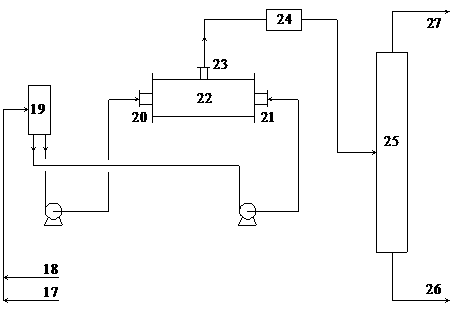

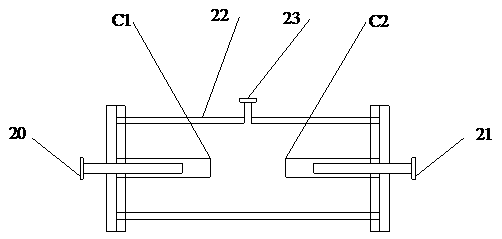

[0042] Raw material C8 aromatics plus xylene concentration 20wt%, HF and BF in the extractant 3 The concentration is 20wt%.

[0043] The feed ratio of extractant and C8 aromatics is 2:1 (volume ratio). The extractant and C8 aromatics are respectively pumped into the impinging flow reactor, and are rapidly mixed with the circulating material in the impinging flow reactor for complexation In the reactive extraction process, the circulating material rate is 200% of the feed amount. The operating temperature was controlled at 3 °C, the residence time was 10 min, and the reaction pressure was 1.5 MPa.

[0044] The experimental results showed that the recovery rate of m-xylene was 88wt%, and the purity of m-xylene was 99.6 wt%.

Embodiment 2

[0046] According to the method of Example 1, the difference is that the operating temperature is changed to 10°C.

[0047] The experimental results showed that the recovery rate of m-xylene was 83 wt%, and the purity of m-xylene was 99.5 wt%.

Embodiment 3

[0049] According to the method of embodiment 1, difference is that residence time becomes 5min.

[0050] The experimental results showed that the recovery rate of m-xylene was 86 wt %, and the purity of m-xylene was 99.7 wt %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com