Vortex grid clarifying pool and clarifying method for enhancing clarifying effect of coagulation reaction in water treatment

A technology of water treatment and clarification tank, which is applied in the direction of settling tanks, etc., can solve the problems that the water purification treatment effect is not very ideal, the flocculation reaction unit and the sludge concentration unit are not enough to meet the purification requirements, etc., so as to increase the volume utilization rate and improve The efficiency of flocculation reaction and the effect of strengthening sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

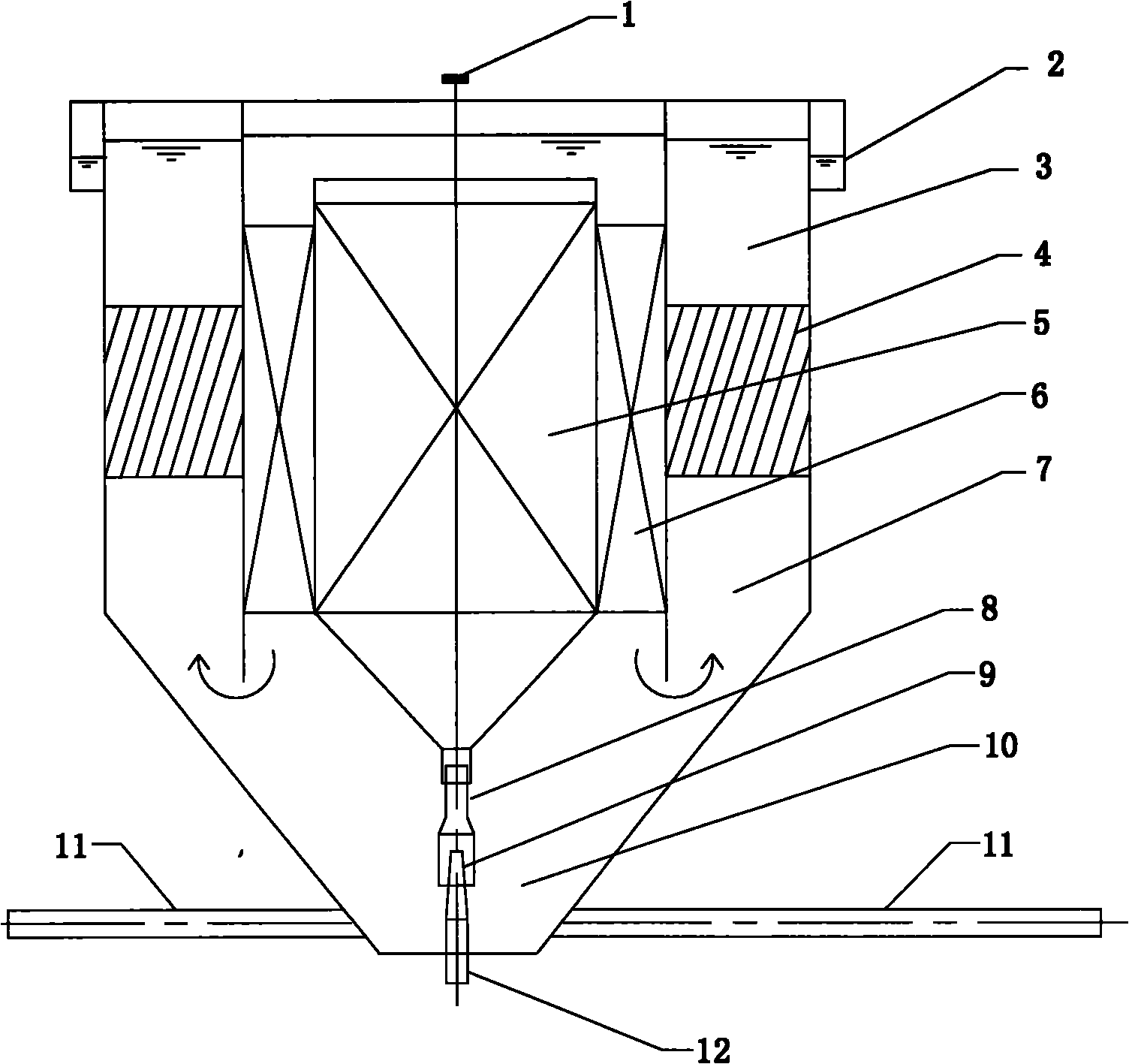

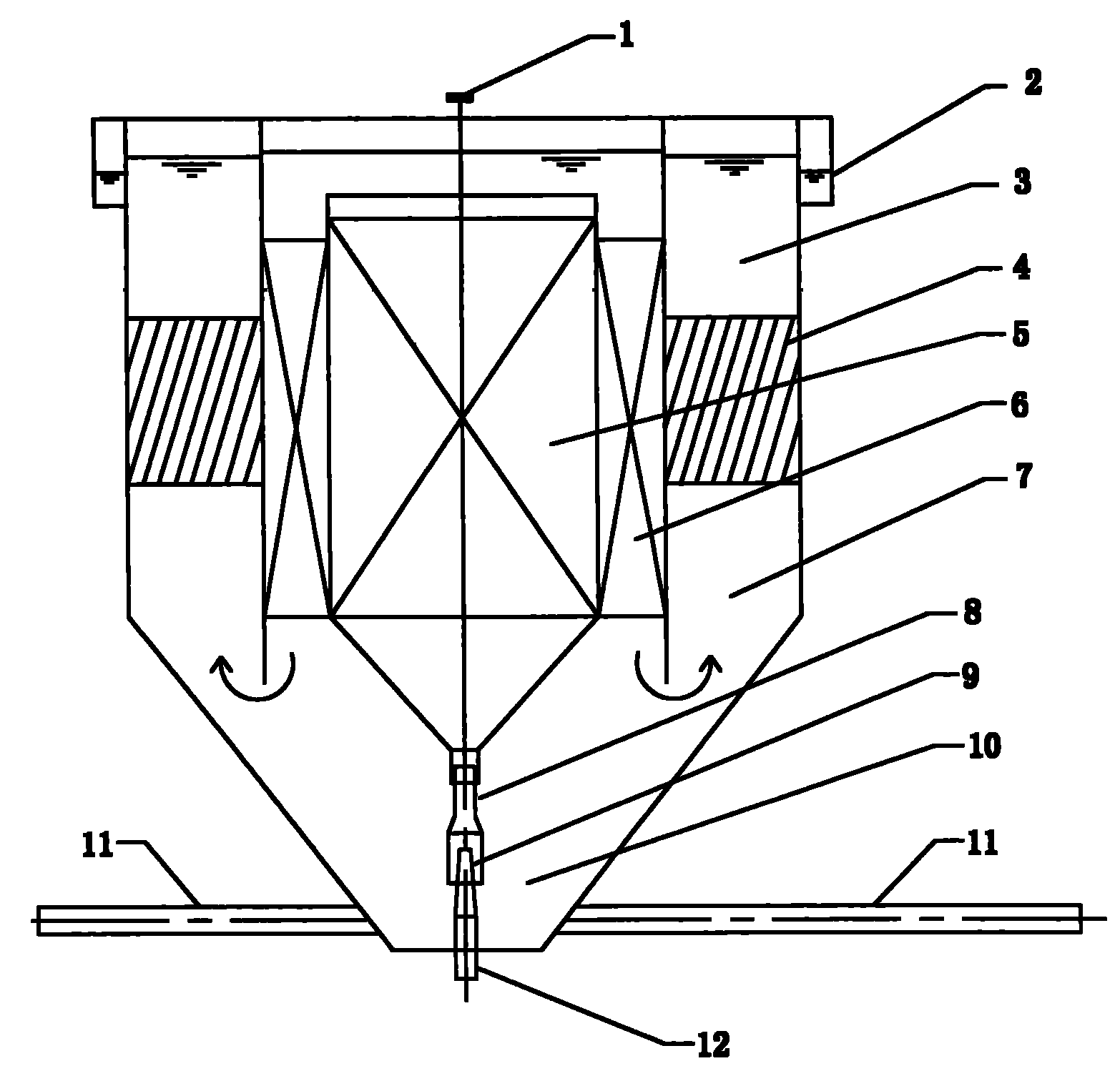

[0019] Embodiment 1, vortex grid clarifier, it comprises flocculation reaction unit, clarification unit and sludge thickening unit, wherein: the first vortex reaction chamber 5 and the second vortex reaction chamber 6 jointly form flocculation reaction unit, the bottom of vortex clarification tank The inlet pipe 12 of the water inlet pipe 12 communicates with the bell mouth at the bottom of the first vortex reaction chamber 5 successively through the nozzle 9, the throat pipe 8; Communication; a vortex grid flocculation reactor 13 is provided in the first vortex reaction chamber 5 and the second vortex reaction chamber 6; the operating rod 1 arranged on the top of the pool controls the vertical rise and fall of the throat pipe 8 through the connecting piece.

Embodiment 2

[0020] Embodiment 2, a clarification method for improving coagulation reaction and sedimentation effect in water treatment, the water that adds coagulant flows through pipeline mixer and enters from the water inlet pipe 12 at the bottom of the vortex clarifier, and then passes through nozzle 9, throat Tube 8 flows into the bell mouth of the first vortex reaction chamber 5 bottom;

[0021] After the water distribution is completed at the bell mouth, it enters the first vortex reaction chamber 5 and the second vortex reaction chamber 6. With the help of the device 13, the flocculation is completed, and the water flows out to the buffer zone 7 from the bottom of the second reaction chamber;

[0022] The floc sediment produced in the flocculation process sinks to the sludge area 10 located below the buffer zone 7 due to gravity, and the water flow passes through the inclined tube or the inclined plate area 4, and then the solid-liquid separation is further performed to complete th...

Embodiment 3

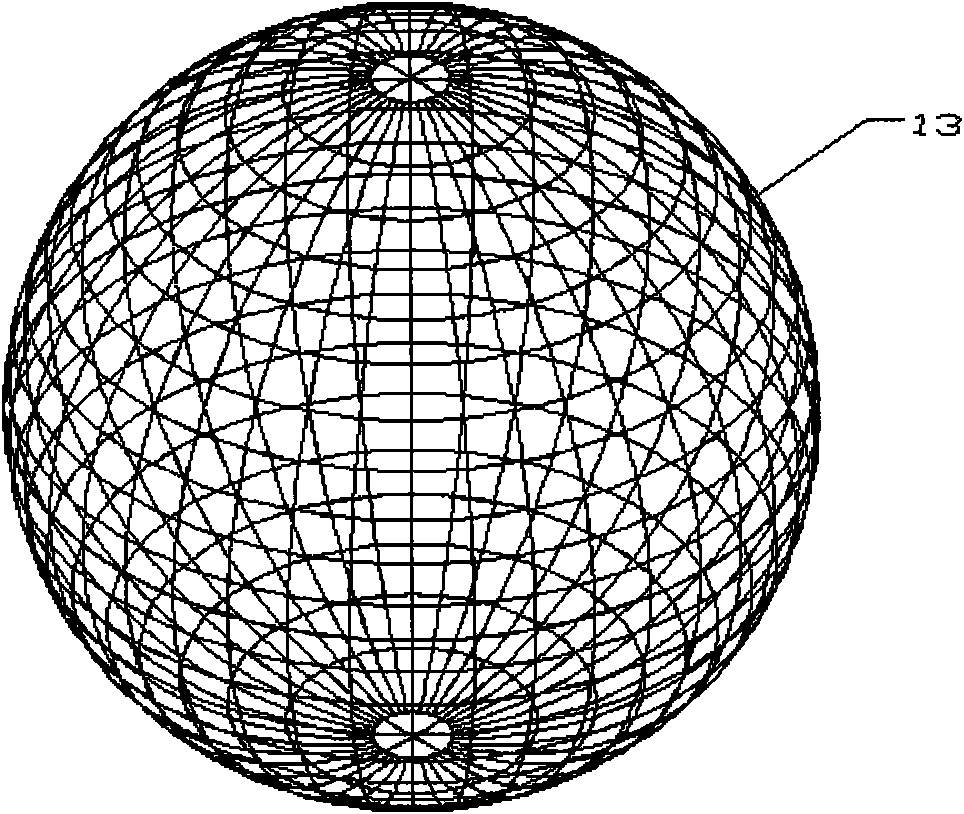

[0023] Embodiment 3. The vortex grid flocculation reactor 13 installed in the first vortex reaction chamber and the second vortex reaction chamber is a hollow sphere with grid-like holes on the spherical surface, and the opening ratio is 50% to 70%. All the other are with embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com