Tile glue

A technology of tile adhesive and re-dispersed latex powder, which is applied in the field of tile adhesive, can solve the problems of inability to paste tiles on old tiles, complicated construction, and weak adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

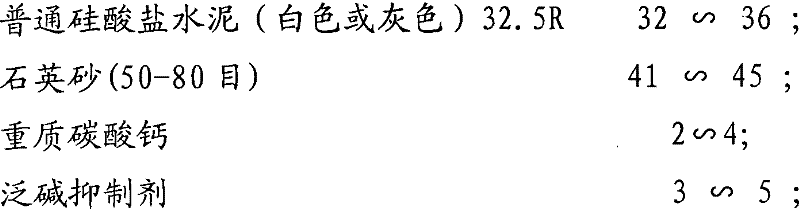

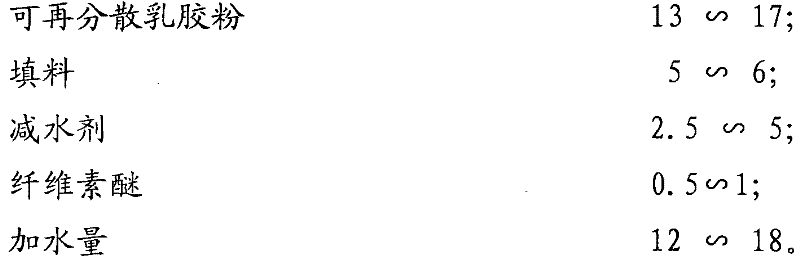

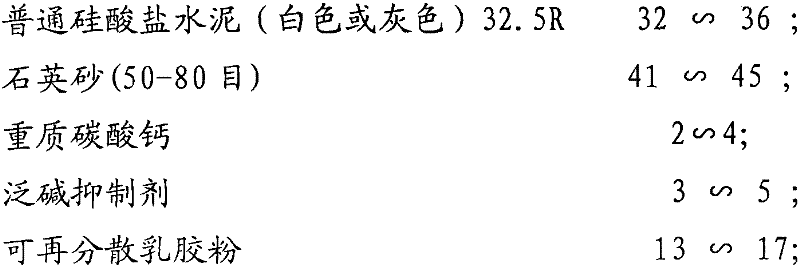

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific embodiments.

[0015] As stated in the present invention, the present invention is improved for tile adhesives, that is, in addition to the components of ordinary Portland cement, quartz sand, redispersible latex powder, ground calcium carbonate, water reducer and cellulose ether , also add a certain amount of ubiquitin inhibitor.

[0016] Due to the addition of efflorescence inhibitors, after construction, there will be no phenomenon of yellowing and efflorescence, and it has the technical effect of maintaining the original color of the appearance after construction. Protection products (i.e. marble tiles)

[0017] In addition, the proportion of latex powder in ordinary tile adhesives is 2.0% to 3.0%. Therefore, when it is used, the tiles must be wet and the base layer must be wet before construction.

[0018] For the tile adhesive of the present invention, we increase the proportion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com