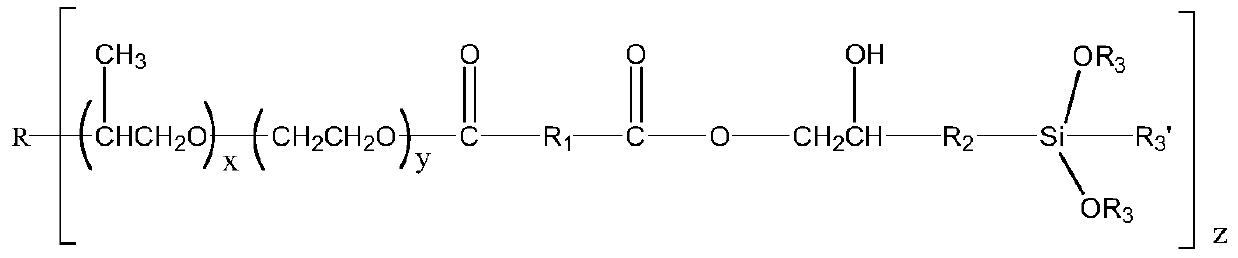

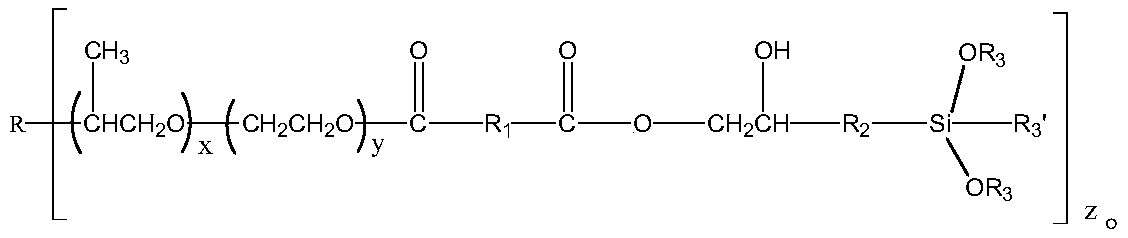

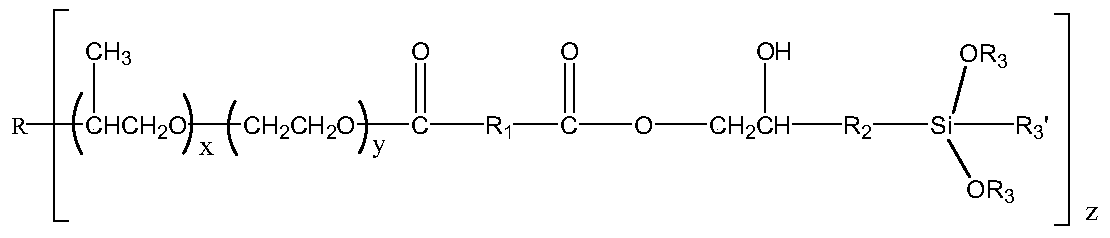

Silane-terminated polyether and preparation method thereof

A technology of silane-terminated polyether and hydroxyl-terminated polyether, which is applied in the direction of polyether adhesives, adhesive types, adhesives, etc., to achieve the effects of wide sources, low prices, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Add 100 g of polypropylene glycol monomethyl ether (x=17, y=0, z=1) with a molecular weight of 1000 g / mol into a three-necked flask equipped with a stirrer and a thermometer, heat up to 80°C and vacuumize for 3 hours, and continue to heat up to 90°C. ℃, and add 10g of maleic anhydride, react for 4h to obtain carboxyl-terminated polyether.

[0043] Raise the temperature of the above-mentioned reactants to 100°C, add 23.6g of γ-glycidyl etheroxypropyl trimethoxysilane and 0.13g (0.1% of total weight) triphenylphosphine catalyst to continue the reaction for 2h, cool down to 50°C and discharge , to obtain silane-terminated polyether.

Embodiment 2

[0045] Add 100 g of polyethylene glycol ether glycol (x=0, y=45, z=2) with a molecular weight of 2000 g / mol to a three-necked flask equipped with a stirrer and a thermometer, heat up to 100° C. for 2 hours, and continue The temperature was raised to 120°C, and 16.8 g of methyl hexahydrophthalic anhydride was added, and reacted for 3 hours to obtain a carboxyl-terminated polyether.

[0046] Raise the temperature of the above-mentioned reactant to 110°C, add 27.8g of γ-glycidyl etheroxypropyltriethoxysilane and 1.44g (1% of total weight) of quaternary ammonium salt catalyst to continue the reaction for 2h, cool down to 50°C and exit material to obtain silane-terminated polyether.

Embodiment 3

[0048] Add 300g of polypropylene glycol ether trihydric alcohol (x=100, y=1, z=3) with a molecular weight of 6000g / mol to a three-necked flask equipped with a stirrer and a thermometer, heat up to 120°C and vacuumize for 1h, continue to heat up to 150°C, and added 22.2g of phthalic anhydride, and reacted for 2h to obtain carboxyl-terminated polyether.

[0049] The temperature of the above-mentioned reactants was raised to 120° C., and 20.9 g of γ-glycidyl etheroxypropyl triethoxysilane, 17.7 g of γ-glycidyl etheroxypropyl trimethoxysilane and 1.80 g (total weight 0.5% ) secondary amine catalyst to continue the reaction for 2 hours, cool down to 50° C. and discharge to obtain silane-terminated polyether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com