A kind of municipal waste treatment process

A technology of municipal waste and processing technology, applied in the direction of grain processing, solid waste removal, etc., can solve the problems of low energy utilization efficiency, insufficient crushing, waste of resources, etc., to reduce energy consumption, improve crushing efficiency, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

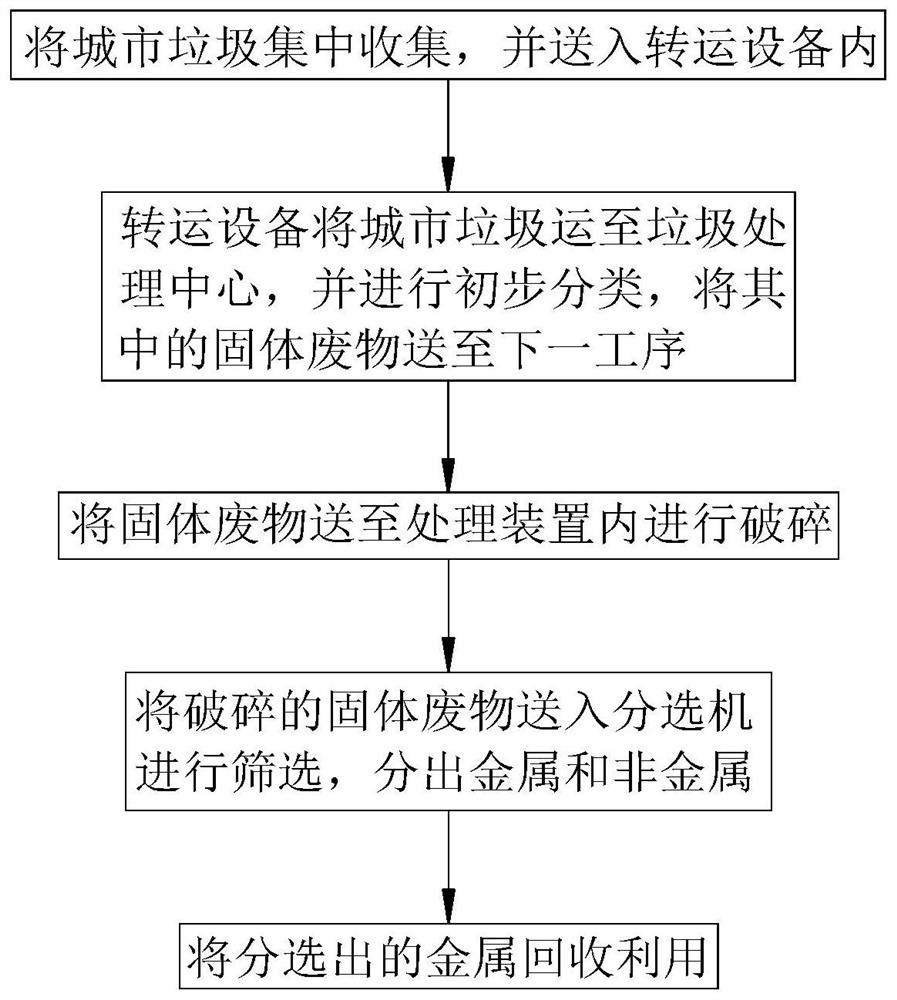

Method used

Image

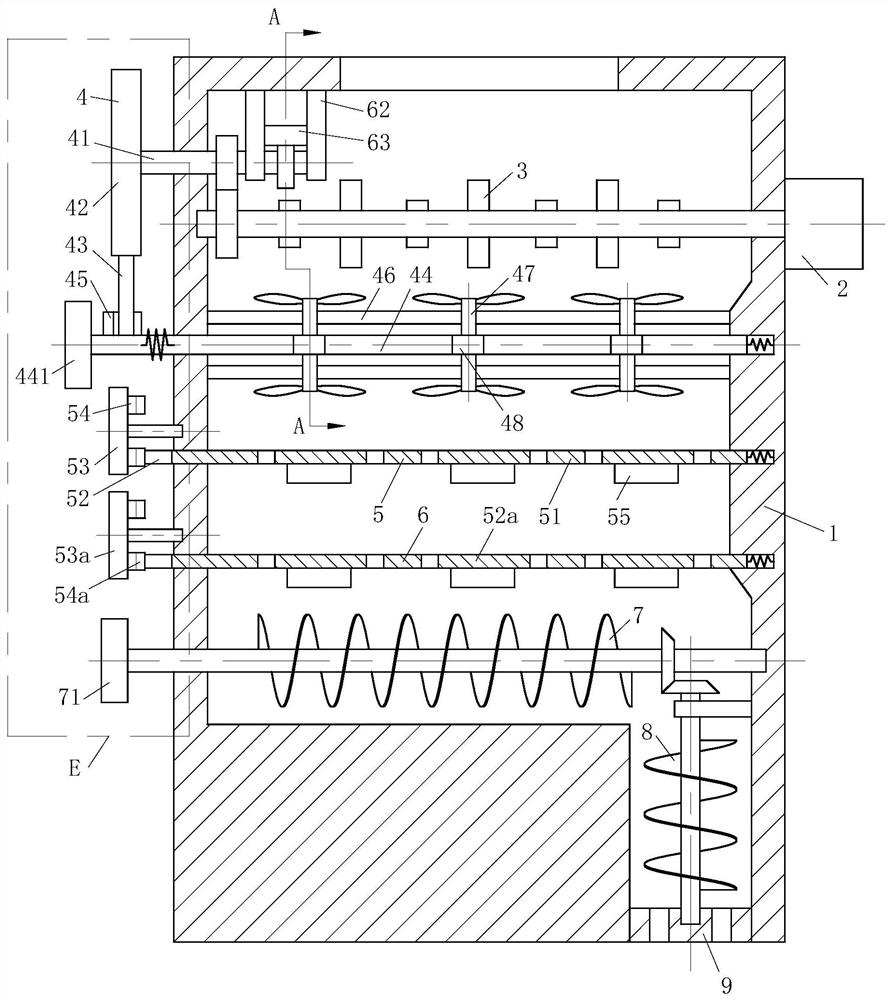

Examples

Embodiment approach

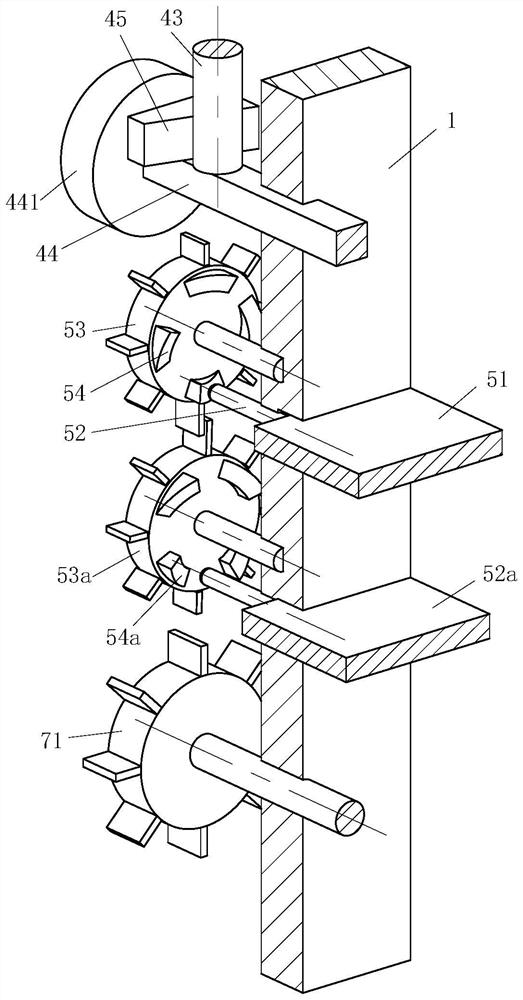

[0038] As an embodiment of the present invention, the end of the rack 44 is fixedly connected with a counterweight 441 , and the counterweight 441 is located outside the box body 1 . During the reciprocating movement of the rack 44, the inertia of the counterweight 441 is used to increase the impact force of the rack 44, so that the rotational speed of the crushing knife increases, and the efficiency of secondary crushing of solid waste is improved.

[0039] As an embodiment of the present invention, at least three groups of crushing modules 4 are provided, and three groups of crushing modules 4 are arranged on the periphery of the crushing roller 3 . Three groups of crushing modules 4 are arranged around the lower side of the crushing roller 3 to fully intercept and secondary crush the solid waste flying out of the crushing roller 3 to improve the efficiency of solid waste crushing.

[0040] As an embodiment of the present invention, one end of the driving shaft 41 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com