Polyester waste silk crushing device and using method thereof

A polyester waste yarn and crushing device technology, which is applied in recycling technology, plastic recycling, etc., can solve problems such as not being able to meet the process requirements of dioctyl terephthalate, affecting the smooth progress of the crushing process, and high toughness of polyester waste yarn. Achieve the effect of improving crushing efficiency and crushing quality, reducing labor intensity of workers, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0051] It should be noted that the structures, proportions, sizes, etc. shown in the accompanying drawings in this specification are only used to cooperate with the contents disclosed in the specification, so as to be understood and read by those who are familiar with the technology, and are not used to limit the implementation of the present invention. Any modification of the structure, the change of the proportional relationship or the adjustment of the size, without affecting the effect that the present invention can produce and the purpose that can be achieved, should fall within the scope of the technical content disclosed in the present invention. within the range.

[0052] At the same time, the terms such as "up", "down", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and clarity, and are not used to limit this specification. The implementable scope of the invention, and the change or adjustment of the relati...

Embodiment 1

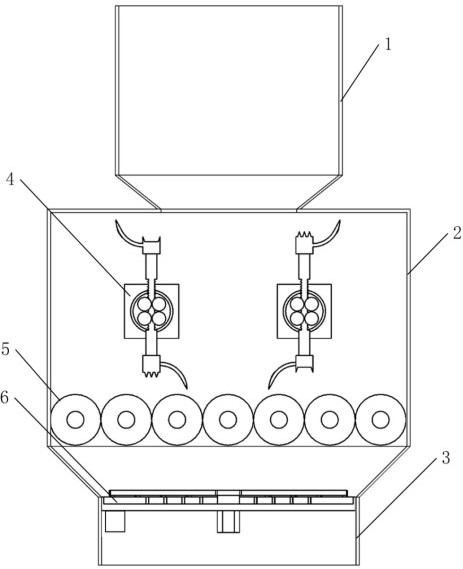

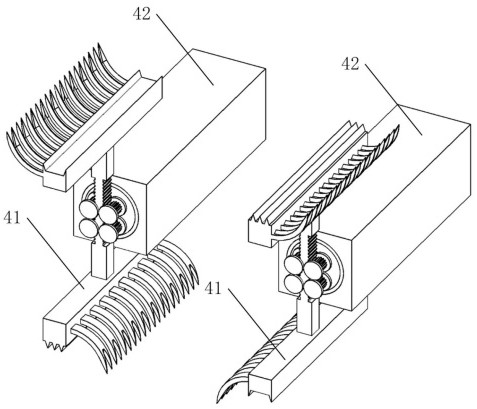

[0054] combined with Figure 1-6 , this embodiment provides a polyester waste silk crushing device, including a silo 1, a crushing silo 2 and a discharge port 3 that are connected in sequence from top to bottom, and a feeding mechanism is arranged in the crushing silo 2 from top to bottom. 4. The first crushing mechanism 5 and the second crushing mechanism 6, the feeding mechanism 4 is located directly below the silo 1, including two feeding rods 41 symmetrically arranged and driving the feeding rods 41 along the polyester waste filaments The drive assembly 42 rotates relatively in the conveying direction; the second crushing mechanism 6 includes a filter screen 61 , and the discharge port 3 is located below the filter screen 61 .

[0055] In the technical solution of this embodiment, the continuous feeding and multi-stage crushing of polyester waste silk are realized by the feeding mechanism 4, the first crushing mechanism 5 and the second crushing mechanism 6 which are seque...

Embodiment 2

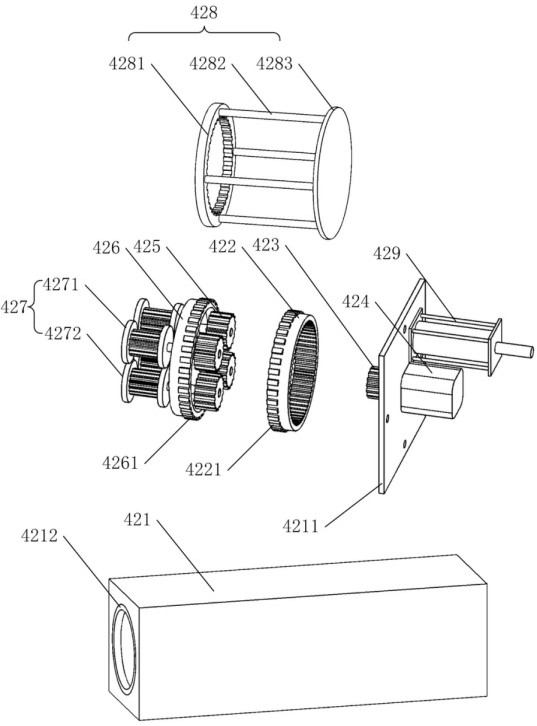

[0058] combined with Figure 2-3 , this embodiment provides an optimized structure of the drive assembly 42, the specific technical solution is as follows, the drive assembly 42 includes a casing 421, one end of the casing 421 is fixed to the side wall of the crushing bin 2, and the other end passes through The bearing 4212 is rotatably connected to the first turntable 426 . One end of the first turntable 426 facing the outside of the housing 421 is provided with two rows of clamping mechanisms 427 in parallel, and one row includes two first turntables 426 connected to the first turntable 426 . One gripping gear 4271, the other row includes two second gripping gears 4272 connected with the alternate driving mechanism, the first gripping gear 4271 and the second gripping gear 4272 are engaged with each other to grip the For the feeding rod 41, the alternate driving mechanism can alternatively drive the first turntable 426 and the second clamping gear 4272 to rotate.

[0059] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com