Multistage crushing device for iron ore mining

A crushing device, iron ore technology, applied in the direction of dispersed particle filtration, mechanical equipment, dispersed particle separation, etc., can solve the problem of ore dust polluting the environment, affecting the quality, efficiency and stability of iron ore crushing, as well as environmental protection, can not fully Broken iron ore, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the embodiments, the invention provides a part of the present invention, which is directed to the embodiment, and can be used to explain the operation principle of the embodiment, and reference These include those skilled in the art will understand other possible embodiments and the advantages of the present invention, and the components in the figures are not drawn to scale, and similar components symbols are often used to represent similar components.

[0034] According to an embodiment of the present invention, there is provided a multi-stage crushing ore opening means.

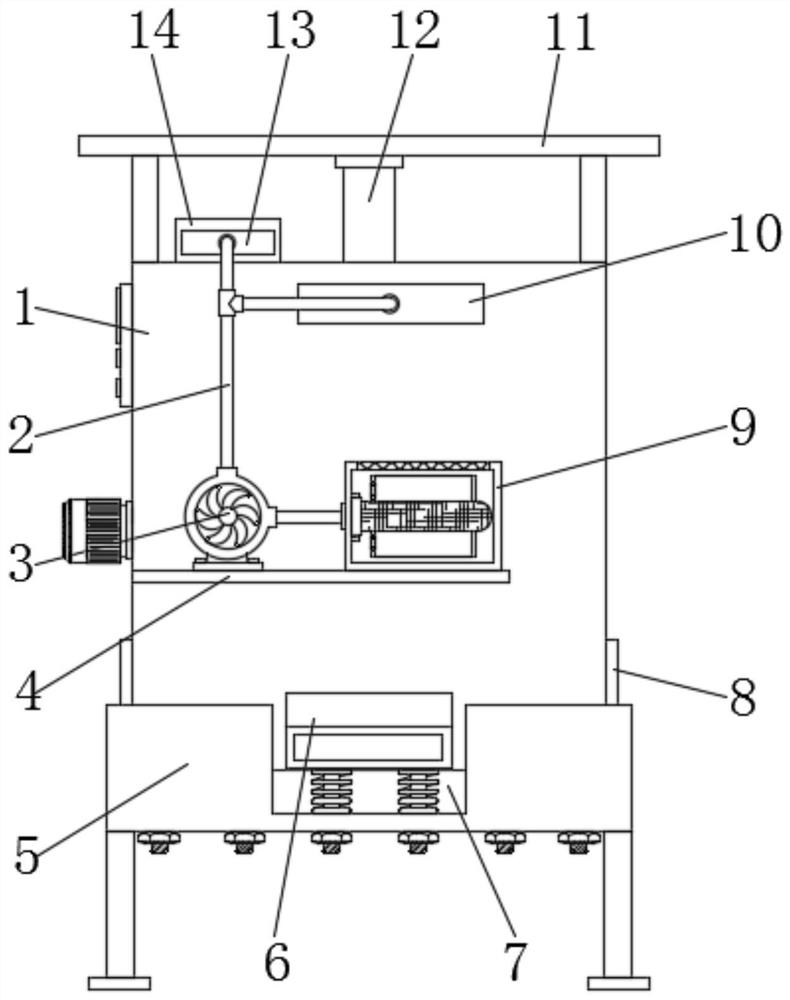

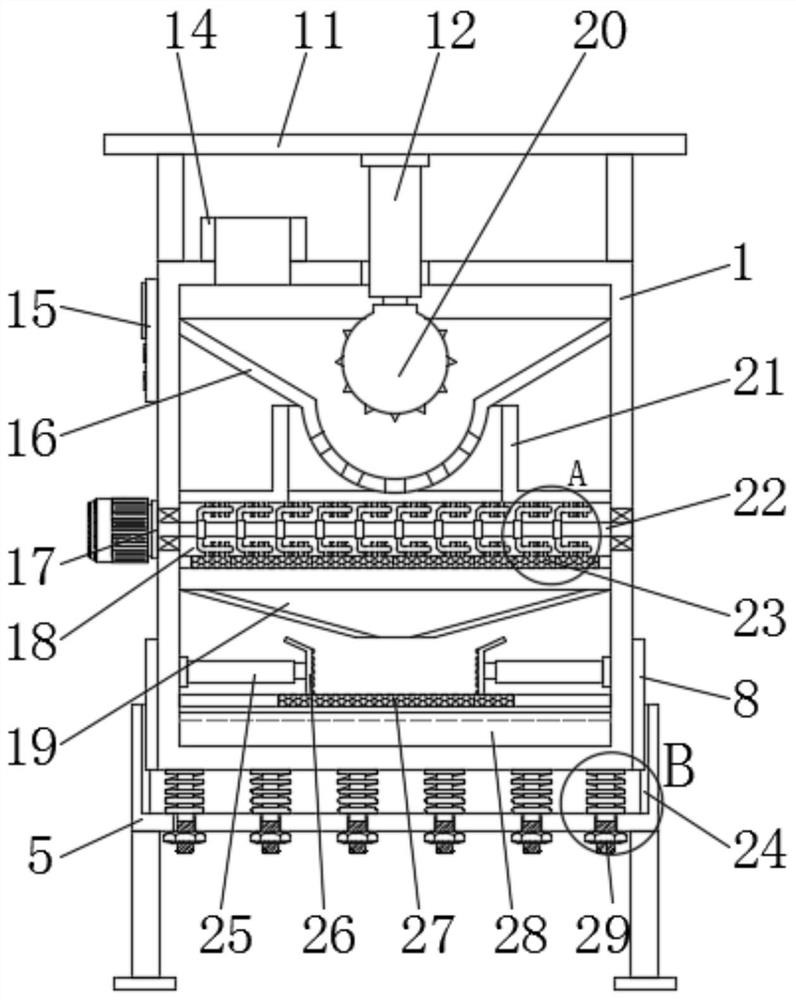

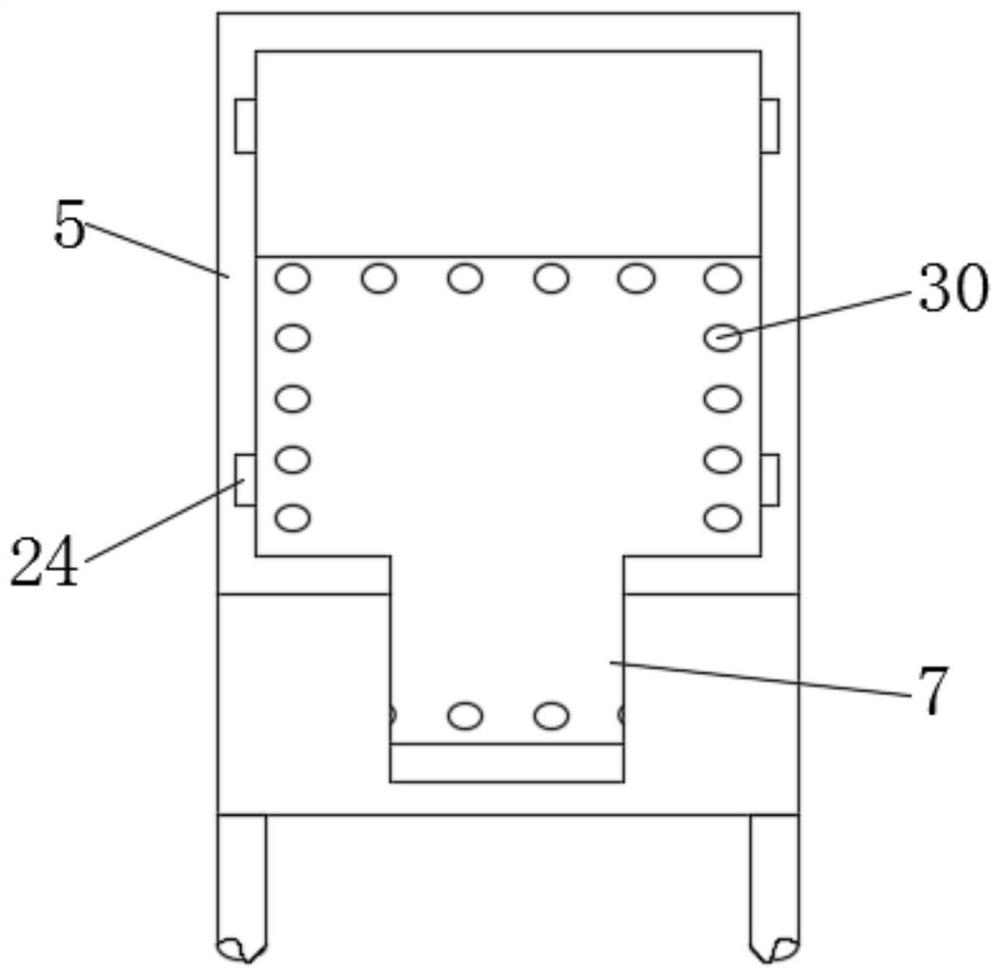

[0035] The present invention is further illustrated in connection with the accompanying drawings and specific embodiments, such as Figure 1-7Shown, according to one embodiment of the present invention is iron apart multistage breaking apparatus, comprising a crushing tank 1, the top surface of the crushing tank 1 defines a feed inlet 14 and feed port 14 are welded above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com