Efficient coal multi-stage crushing equipment for coal mine exploitation

A kind of crushing equipment and coal mine technology, applied in the direction of grain processing, etc., can solve the problems of low crushing efficiency, single function, poor crushing effect, etc., and achieve the effect of improving crushing effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

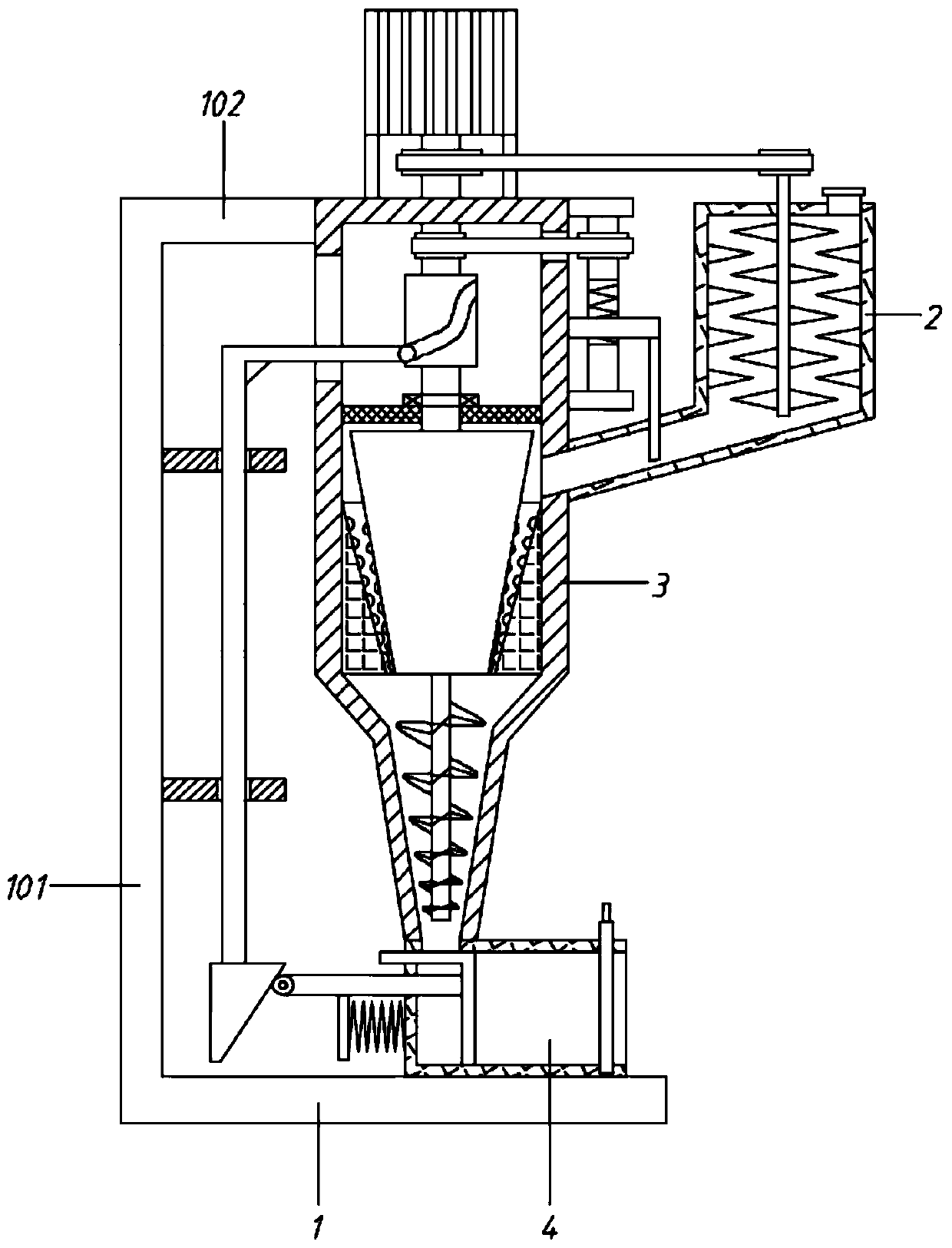

[0045] A high-efficiency multi-stage crushing equipment for coal materials used in coal mine development, including a casing 3 and a feeding hopper 2;

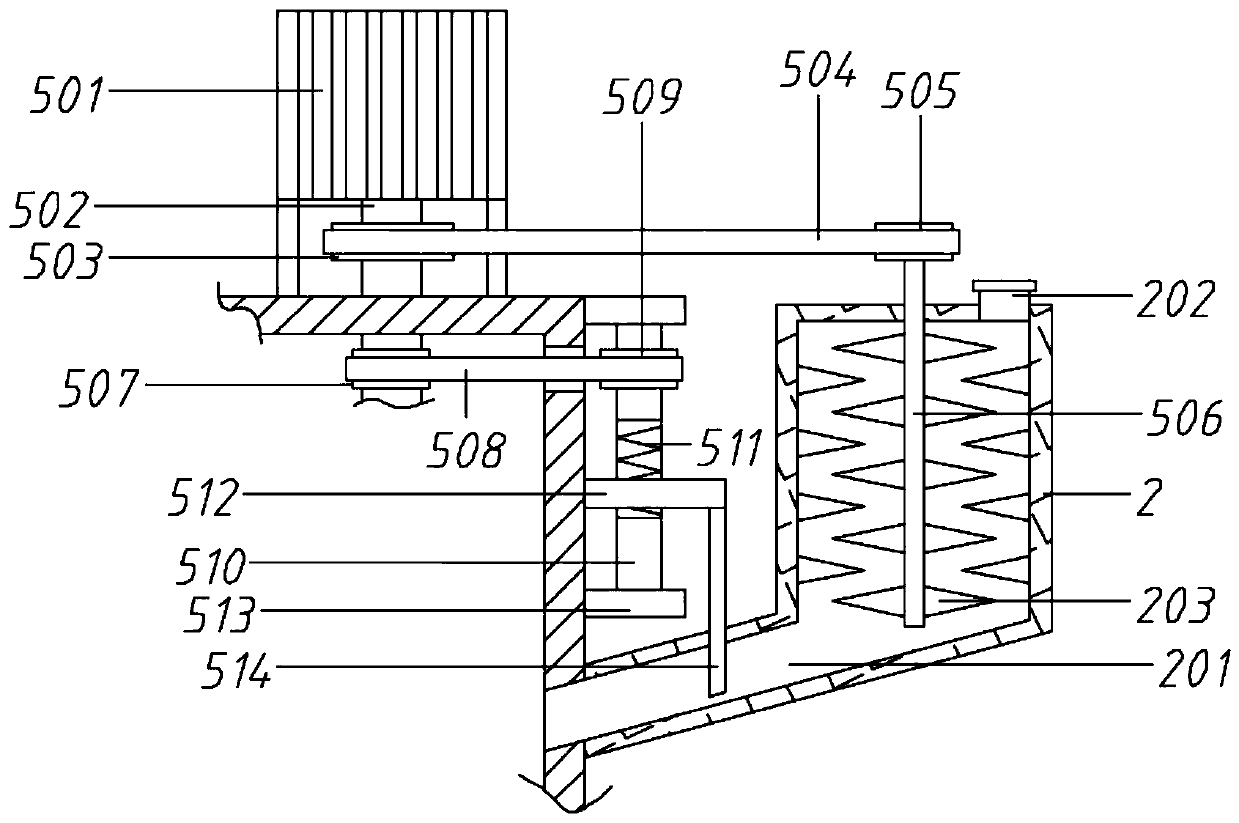

[0046] A partition 302 is fixed inside the shell 3, which divides the shell 3 into a cam chamber 301 and a grinding chamber 303; the inner wall of the grinding chamber 303 is fixed with a grinding table 304, and the grinding table 304 is processed with a round table with a large upper and a lower one. The top of the housing 3 is equipped with a servo motor 501, the output end of the servo motor 501 is connected downwards with a rotating shaft 502, and the rotating shaft 502 passes through the partition plate 302 and stretches into the grinding chamber 303 and is connected with the grinding end 701. The end 701 cooperates with the round table through groove to form a grinding channel;

[0047] The feed hopper 2 is arranged on the right side of the housing 3, and the bottom communicates with the upper part of the grinding chambe...

Embodiment 2

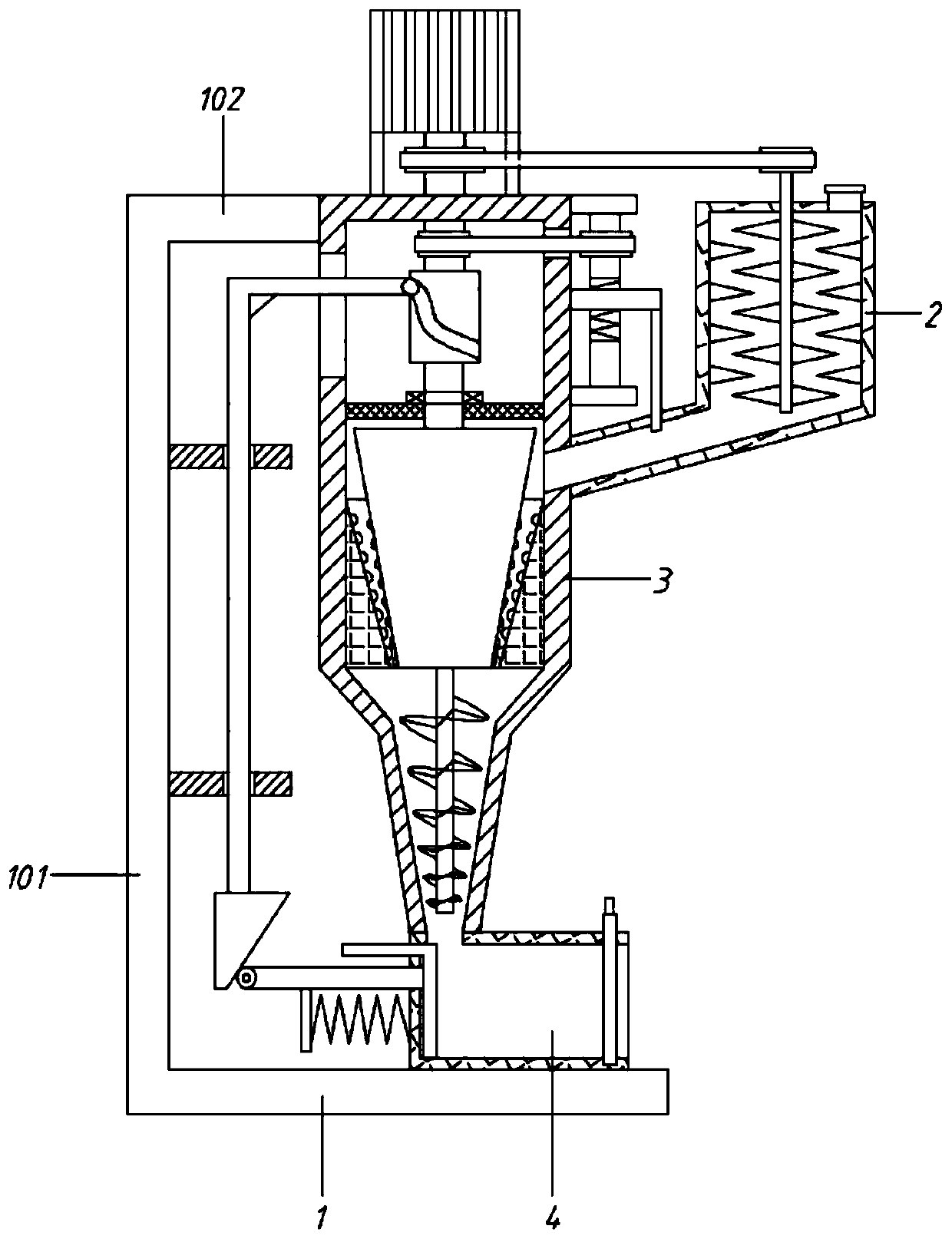

[0051] A high-efficiency multi-stage crushing equipment for coal materials used in coal mine development, including a casing 3 and a feeding hopper 2;

[0052] A partition 302 is fixed inside the shell 3, which divides the shell 3 into a cam chamber 301 and a grinding chamber 303; the inner wall of the grinding chamber 303 is fixed with a grinding table 304, and the grinding table 304 is processed with a round table with a large upper and a lower one. The top of the housing 3 is equipped with a servo motor 501, the output end of the servo motor 501 is connected downwards with a rotating shaft 502, and the rotating shaft 502 passes through the partition plate 302 and stretches into the grinding chamber 303 and is connected with the grinding end 701. The end 701 cooperates with the round table through groove to form a grinding channel;

[0053] The feed hopper 2 is arranged on the right side of the housing 3, and the bottom communicates with the upper part of the grinding chambe...

Embodiment 3

[0058] A high-efficiency multi-stage crushing equipment for coal materials used in coal mine development, including a casing 3 and a feeding hopper 2;

[0059] A partition 302 is fixed inside the shell 3, which divides the shell 3 into a cam chamber 301 and a grinding chamber 303; the inner wall of the grinding chamber 303 is fixed with a grinding table 304, and the grinding table 304 is processed with a round table with a large upper and a lower one. The top of the housing 3 is equipped with a servo motor 501, the output end of the servo motor 501 is connected downwards with a rotating shaft 502, and the rotating shaft 502 passes through the partition plate 302 and stretches into the grinding chamber 303 and is connected with the grinding end 701. The end 701 cooperates with the round table through groove to form a grinding channel;

[0060] The feed hopper 2 is arranged on the right side of the housing 3, and the bottom communicates with the upper part of the grinding chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com