Multi-stage grain crushing device

A pulverizing device and grain technology, applied in grain processing and other directions, can solve the problem of insufficient grain pulverization, and achieve the effects of improving efficiency, avoiding staying and improving crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

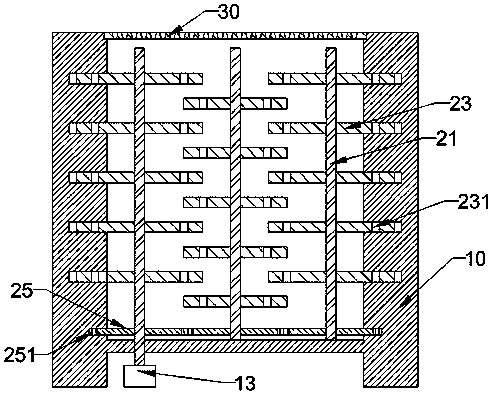

[0021] The reference signs in the drawings of the description include: the casing 10 , the motor 13 , the rotating shaft 21 , the blade 23 , the through hole 231 , the impeller 25 , the ring gear 251 , and the screen 30 .

[0022] Such as figure 1 The shown multi-stage grain crushing device includes a casing 10, the upper end of the casing 10 is provided with a feeding port, the inside of the casing 10 is provided with a crushing chamber, and a crushing mechanism is arranged in the crushing chamber; wherein, the upper part of the crushing chamber is provided with There is a screen 30, and the two ends of the screen 30 are connected to the inner wall of the casing 10. In order to avoid the phenomenon of clogging of the screen holes, the aperture size of the screen holes on the screen 30 decreases sequentially from top to bottom;

[0023] The pulverizing mechanism comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com