An intelligent pulping system for producing vermicelli

A pulping and intelligent technology, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems that noodles and lump solids cannot be filtered, affect the recycling and utilization of noodles, and affect the quality of noodles pulping, etc. , to achieve the effect of saving production cost, shortening processing time and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

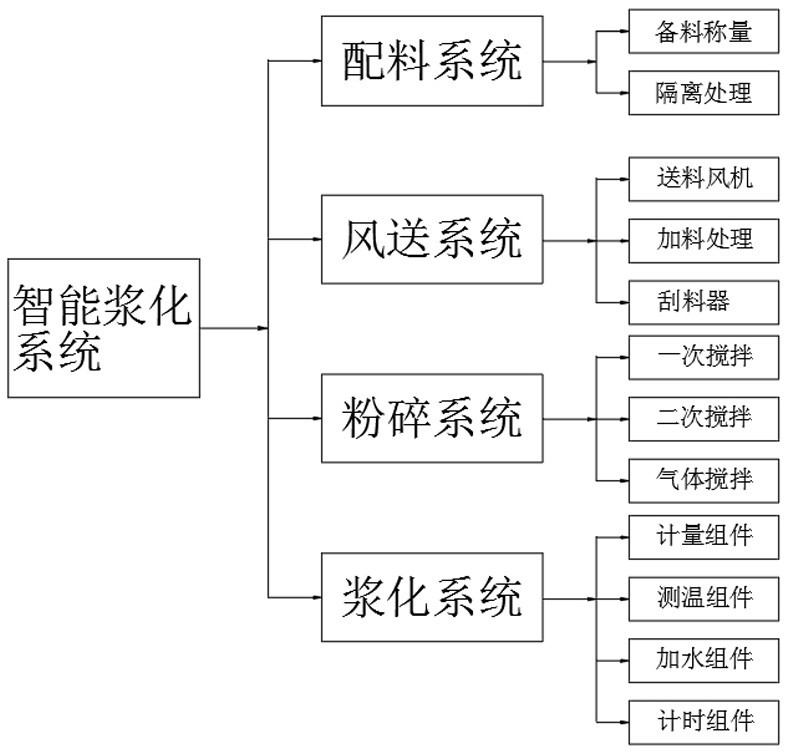

[0034] Example: such as figure 1 As shown, the present invention provides a technical solution, an intelligent pulping system for producing vermicelli, including a batching system, an air delivery system, a crushing system and a pulping system, the batching system includes weighing and isolation processing, and the air delivery system includes Feeding fan, feed processing and scraper, crushing system includes primary stirring, secondary stirring and gas stirring, slurrying system includes metering component, temperature measuring component, water adding component and timing component.

[0035] According to the above-mentioned technical scheme, the specific implementation operation of the batching system is as follows:

[0036] The preparation and weighing includes the weighing container and the electronic scale. Put the noodle head in the weighing container, and then use the electronic scale to weigh the total weight of the weighing container and the noodle head, and subtract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com