Contaminated soil remediation machine and contaminated soil remediation method

A technology of contaminated soil and remediation machine, applied in the field of contaminated soil remediation machine and contaminated soil remediation, can solve the problems of low remediation efficiency, high labor intensity, single remediation scope, etc., and achieve the effect of improving the remediation effect and improving the crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

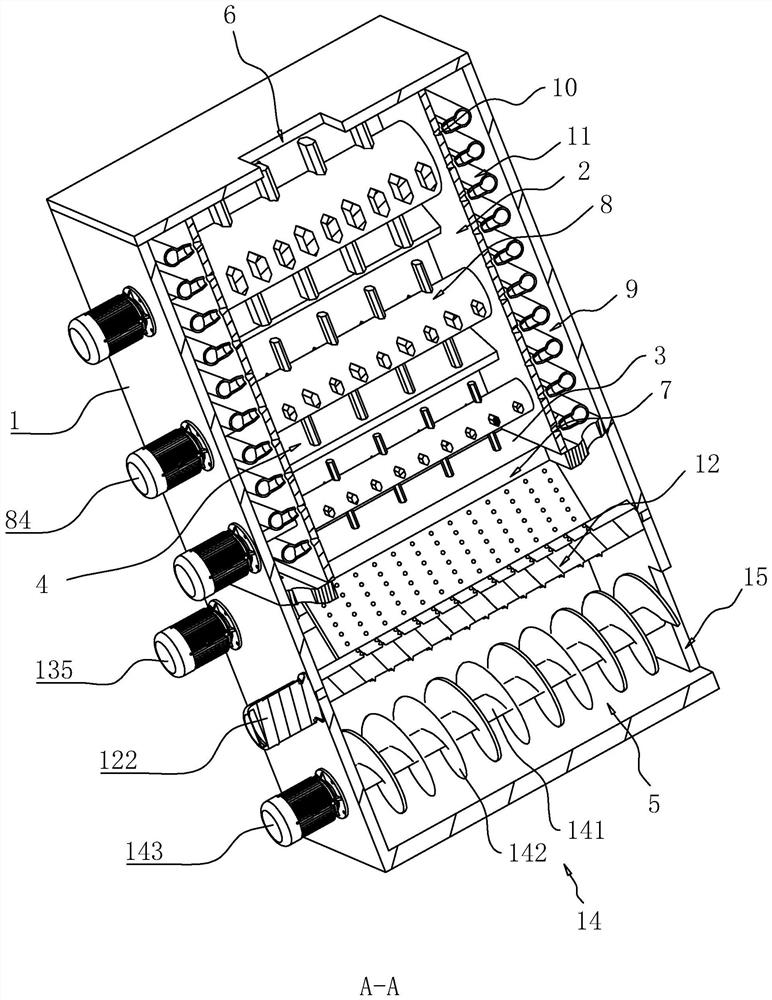

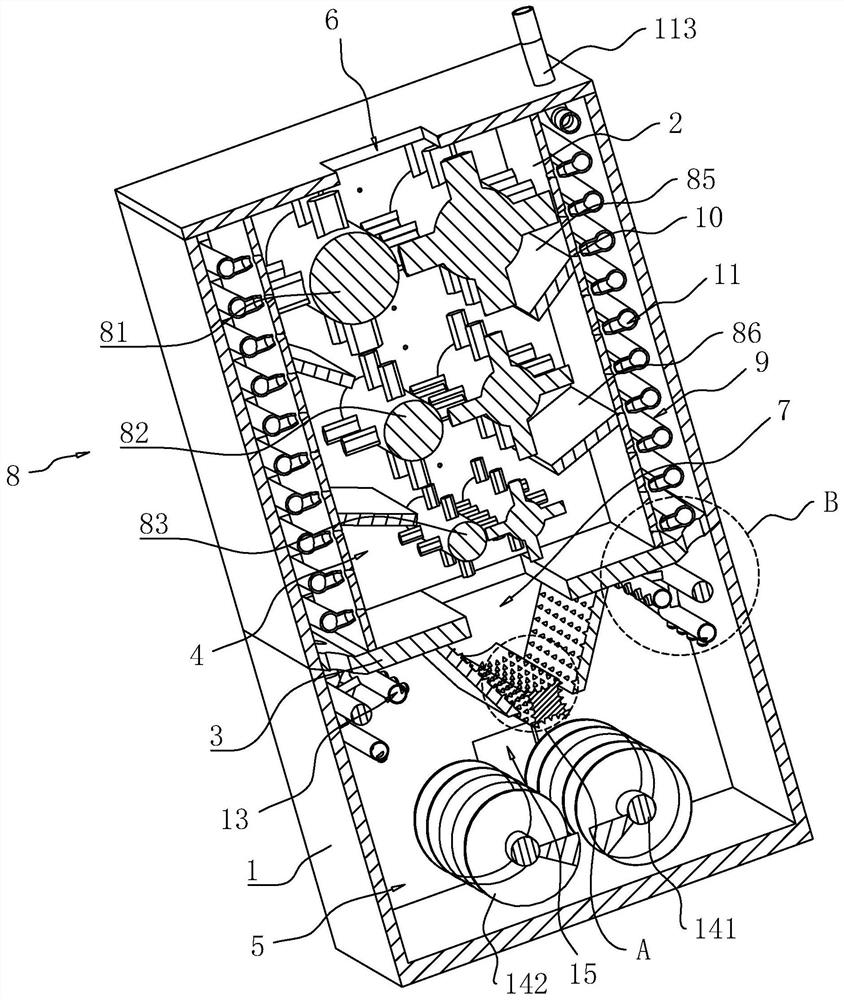

[0049] The following is attached Figure 1-6 The application is described in further detail.

[0050] The embodiment of the present application discloses a contaminated soil remediation machine, referring to figure 1 , a contaminated soil remediation machine includes a square remediation box 1.

[0051] refer to figure 2 and image 3 , the interior of the repair box 1 is provided with a partition plate 3, the upper and lower surfaces of the partition plate 3 are respectively enclosed with the inner wall of the repair box 1 to form a crushing chamber 4 and a repair chamber 5, and the upper surface of the partition plate 3 A crushing box 2 is provided, and the top wall of the crushing box 2 and the top wall of the repairing box 1 are provided with corresponding feeding ports 6, and the bottom wall of the crushing box 2 and the middle side wall of the partition plate 3 are provided with corresponding discharge ports. Mouth 7.

[0052] The soil to be treated and repaired is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com