House refuse treatment method

A treatment method and technology for domestic waste, applied in the fields of biofuels, solid fuels, organic fertilizers, etc., can solve the problems of long production cycle, high operating cost, land waste, etc., reduce power and labor consumption, improve screening quality, The effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

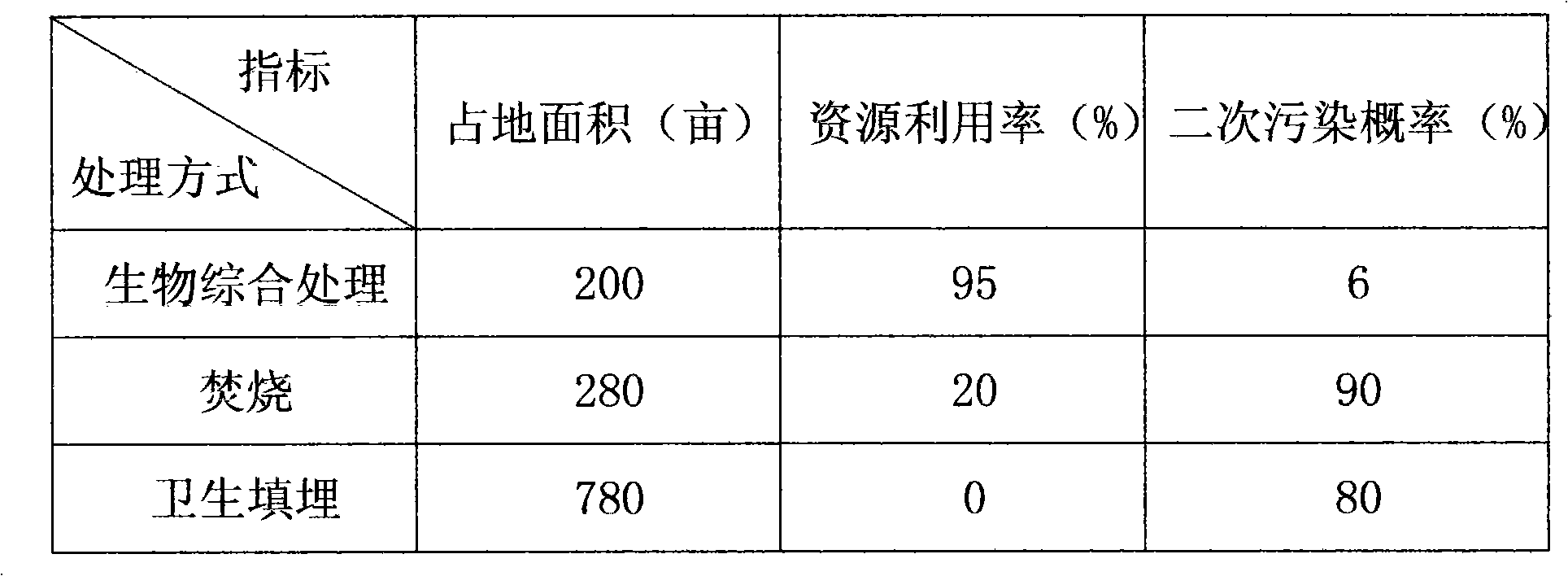

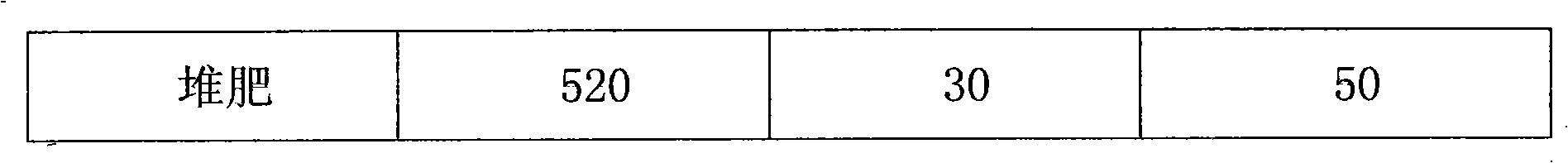

Problems solved by technology

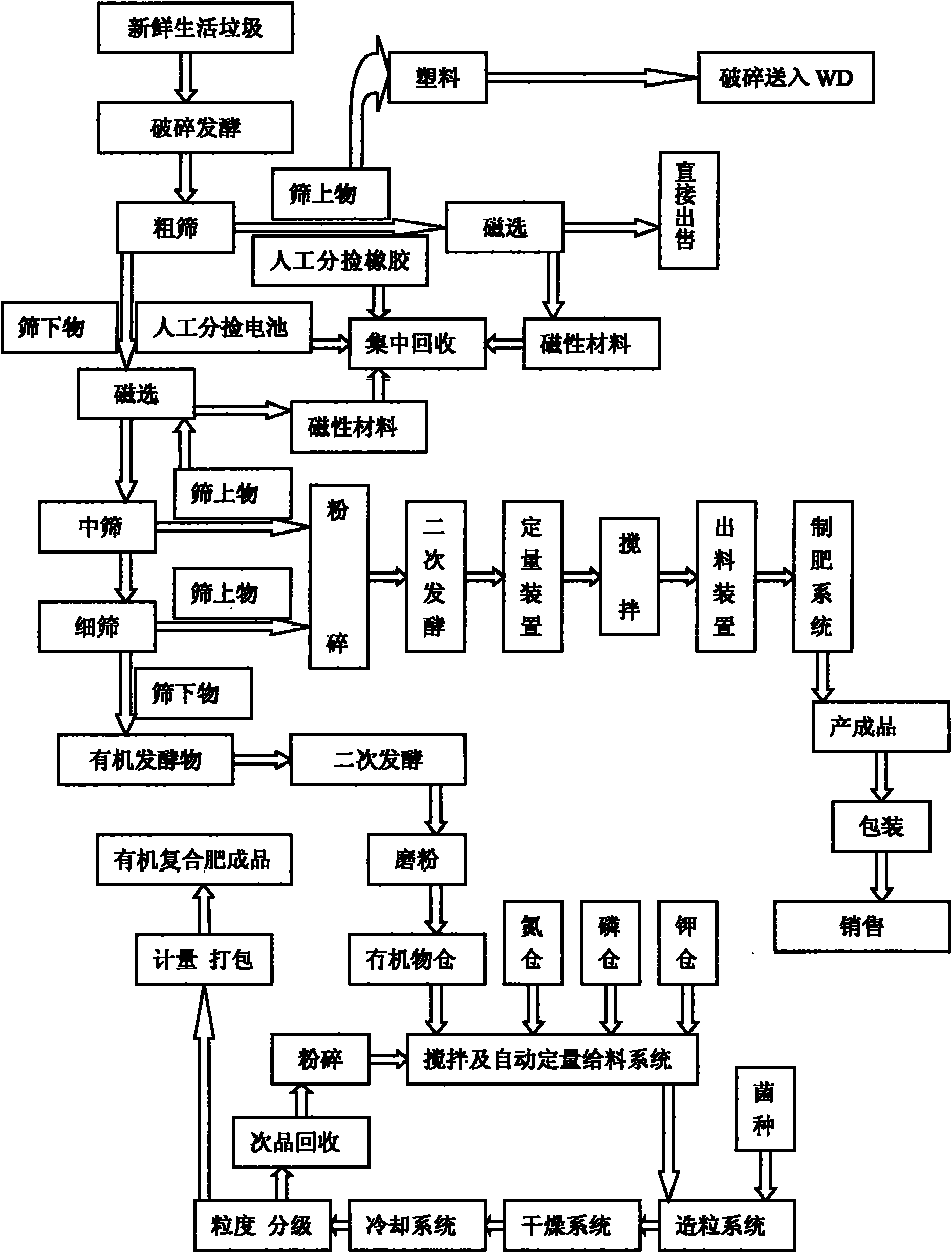

Method used

Image

Examples

Embodiment Construction

[0032] The present invention realizes low construction investment and low operating costs in terms of process design, including three non-repetitive, non-intersecting, mutually independent and mutually connected components: a fermentation workshop, a screening workshop, and a deep processing workshop. This non-intersection, non-repetition and assembly line connection eliminates redundant construction, reduces construction area, avoids duplication of labor, and saves manpower and power consumption in construction investment and operating costs. This process adopts open aerobic fermentation, and the requirements for the workshop in the fermentation stage are low, and there are no special requirements for the screening workshop and deep processing workshop. The fermentation and screening parts can be made into simple steel structure workshops, which saves construction investment.

[0033]The harmless guarantee of the present invention is reflected in the elimination of toxic and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com