Rice eddy-vibrating sieve

A technology of rotary vibrating screen and rice, applied in the direction of screen, solid separation, grid, etc., can solve the problems of unreasonable structure design, increased work cost, low efficiency, etc., to avoid the decline of screening rate, high production efficiency, avoid accumulated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

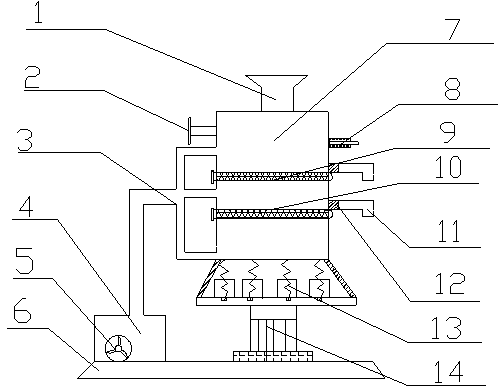

[0009] Such as figure 1 Shown, a kind of rice rotary vibration sieve, it comprises filter screen, sub-sieve chamber 7, base 6 and be located at the vibrating motor 14 above base 6, described sub-sieve chamber 7 is three-dimensional box structure, described sub-sieve chamber 7 is provided with a feed port 1 above, and the filter screen is composed of a primary filter screen 9 and a secondary filter screen 10 arranged at intervals from top to bottom, and the same side of the sub-screen chamber 7 is respectively provided with the The material receiving pipe 11 adapted to the primary filter screen 9 and the secondary filter sieve 10, the mouth of the material receiving pipe 11 is provided with a movable valve 12, and the bottom of the sub-sieve chamber 7 is provided with a rotary vibration mechanism 13. The bottom of the vibration mechanism 13 is connected with the output end of the vibration motor 14.

[0010] Preferably, the primary filter screen 9 and the secondary filter scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com