Sorting system of mineralized refuse and sorting process of mineralized refuse

A sorting system and technology for mineralizing garbage, applied in solid separation, magnetic separation, chemical instruments and methods, etc., can solve the problems of low screening efficiency, poor screening quality, and complex components, and achieve screening quality screening. Convenience, convenient screening, good screening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

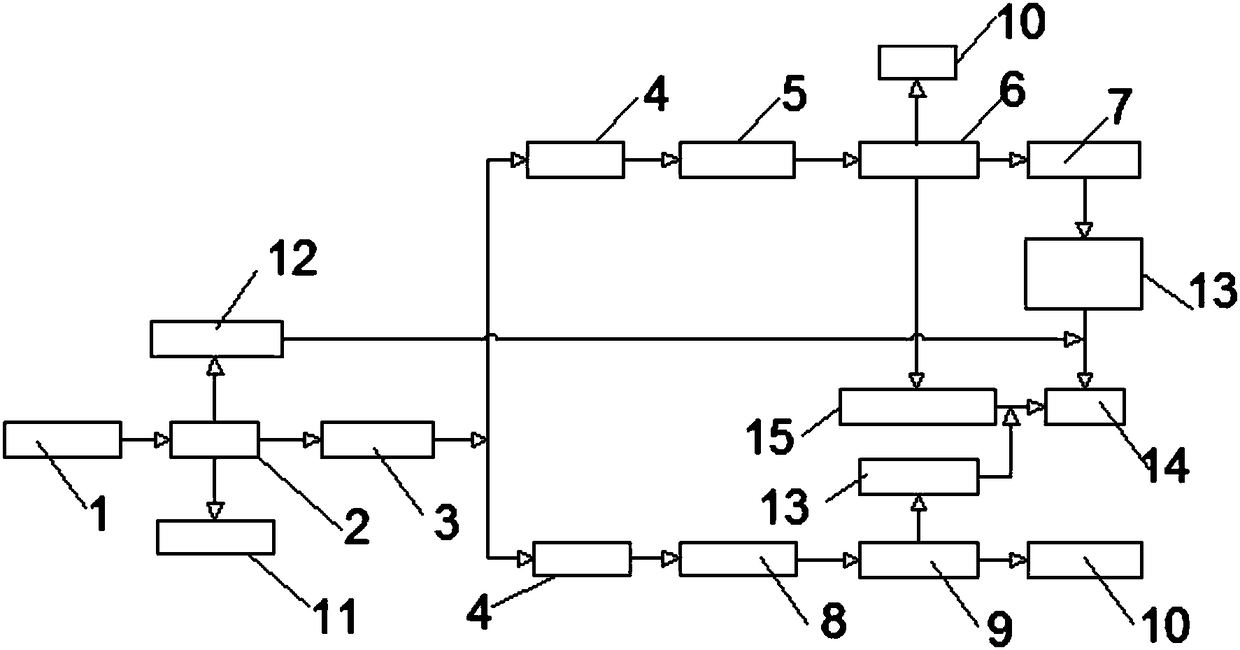

[0040] figure 1 It is a structural block diagram of a mineralized waste sorting system provided in Embodiment 1 of the present invention.

[0041] Such as figure 1 As shown, the mineralized waste sorting system provided by the embodiment of the first aspect of the present invention includes a sequentially connected manual sorting system, a screening system and a sorting system;

[0042] The manual sorting system sorts out waste wood, plastics and rubber;

[0043] The screening system screens out coarse-grained materials with larger diameters and fine-grained materials with smaller diameters;

[0044] The sorting system includes a coarse-grained sorting system and a fine-grained sorting system, the coarse-grained sorting system screens out the plastic in the coarse-grained material, and the fine-grained sorting system screens out the fine-grained material The fine aggregate 10 inside is screened out, and the fine aggregate 10 is used for building materials.

[0045] The scr...

Embodiment 2

[0079] In this embodiment two, an electrical control system is also provided. The electrical control system is an important part of the entire treatment system. Since the construction environment of the garbage disposal site is far worse than that of a construction site, it is generally open-air, and workers need to be equipped with protective masks. The requirements for safe operation are higher than those for factories. In order to reduce the number of operators and realize the automation of the waste disposal production line, the electrical system is equipped with a PLC programmable controller to meet the automation requirements of the production line startup sequence and workflow.

[0080] Since the feeder, belt conveyor, screening system and sorting system are sensitive to real-time changes in the state, composition and moisture content of the materials being processed, they have strict requirements on the rotational speed or line speed. If certain measures are not taken, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com