Iron-titanium ore magnetic separator

A magnetic separator and ferro-titanium technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low magnetic separation efficiency, complex structure, high cost, etc., achieve high magnetic separation efficiency and optimize the magnetic system Structure, effect of improving wear resistance and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The orientation words "up", "down" and "top", "bottom", "inside" and "outside" involved in the present invention are all associated with the appended figure 1 in the same direction.

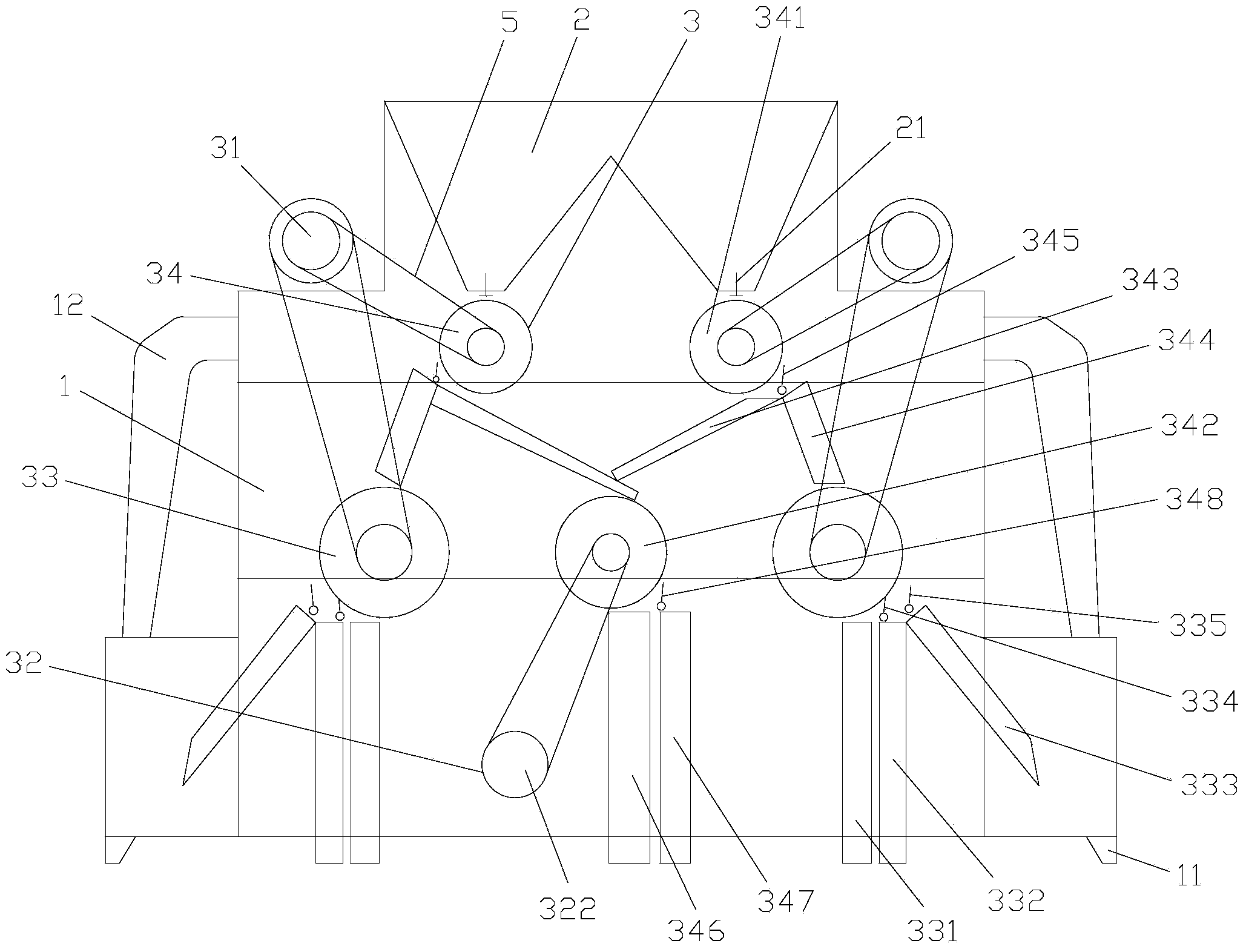

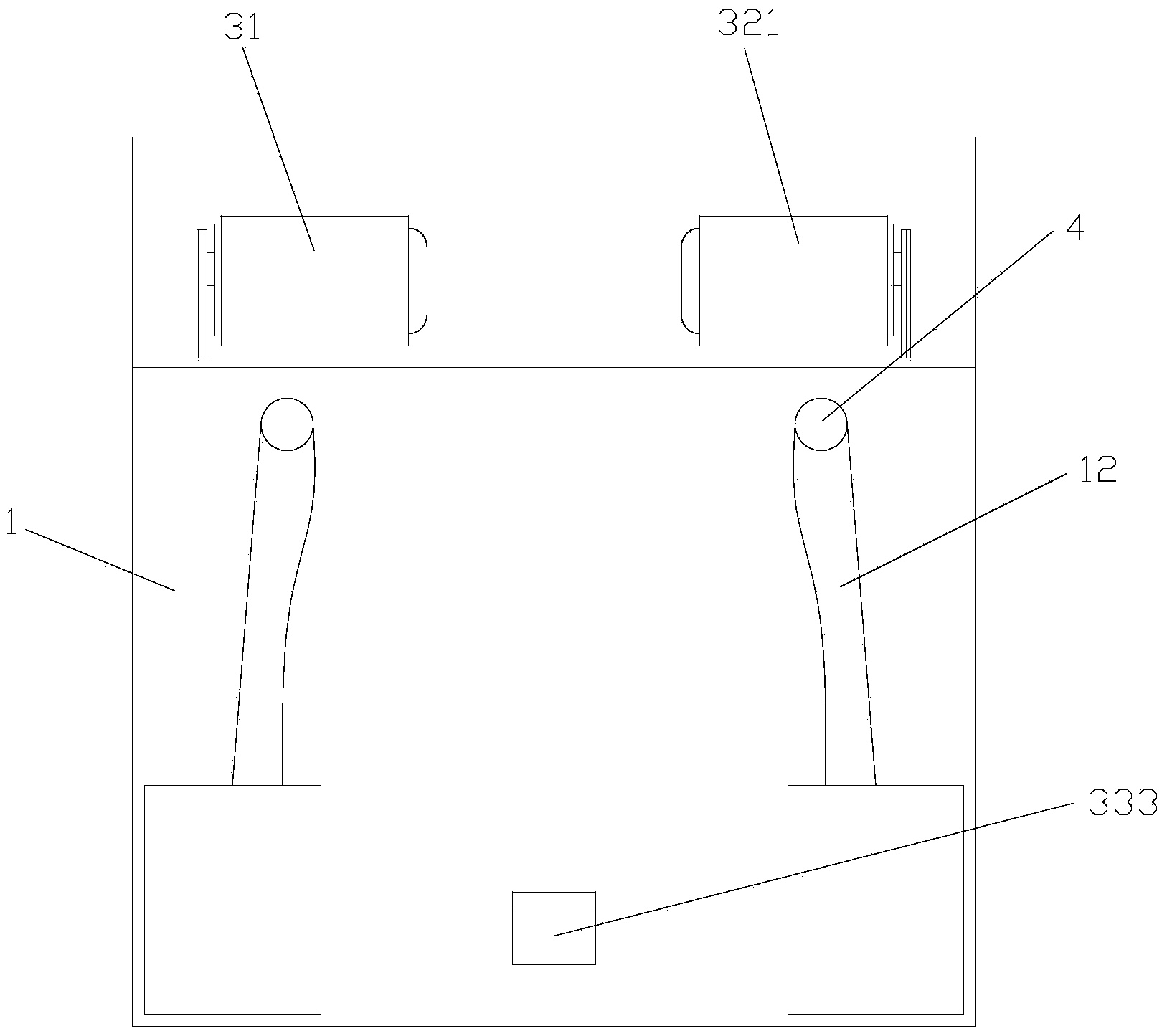

[0019] Such as figure 1 , 2 As shown, the ferro-titanium magnetic separator of the present invention includes a frame 1, a feed hopper 2, a magnetic separation mechanism 3 and a dust exhaust fan 4.

[0020] The frame 1 is a symmetrical box-type structure, and its bottom is symmetrically provided with support feet 11 , and a pair of opposite side walls are respectively symmetrically provided with at least one pair of dust outlets 12 .

[0021] The feeding hoppers 2 are at least one pair symmetrically arranged on the inner side of the top of the frame 1, and each feeding hopper 2 is an inverted cone structure, and its upper feeding port is flush with the top of the frame 1 and is open. The outlet at the bottom is located inside the top of the frame 1 and is also provided with a feed regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com