Intermittent rotating separation type drum screen for mining area of coal mine

A separation type, trommel screen technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of many processes, inconvenient use, affecting the screening quality, etc., to improve the screening quality, good practical effect, and ensure screening efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

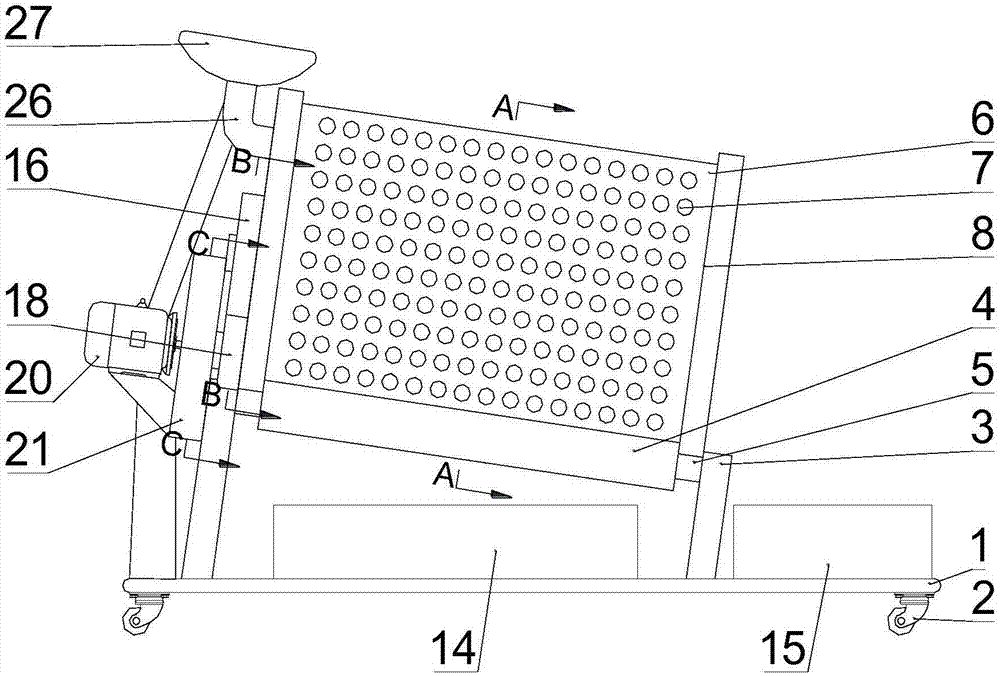

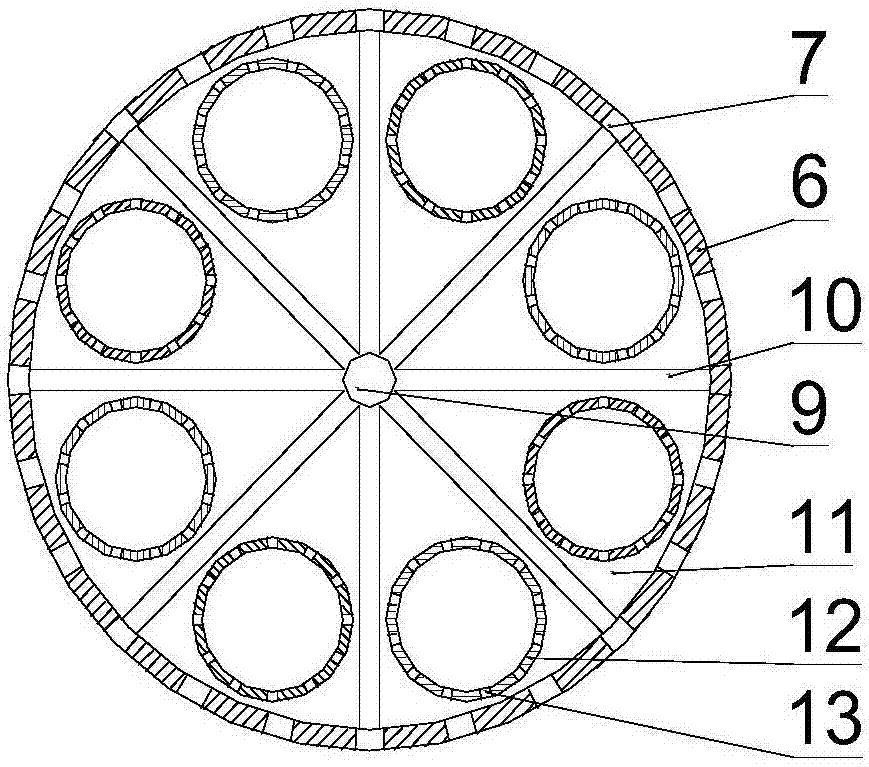

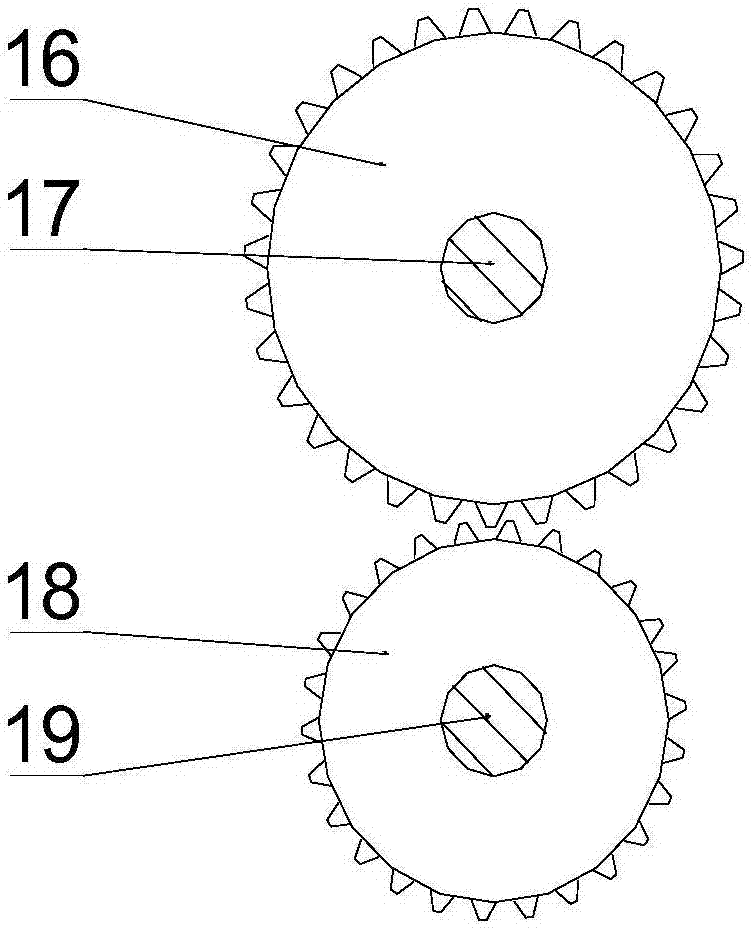

[0019] see Figure 1-4 , an intermittently rotating partitioned drum screen for coal mining areas, including a bottom plate 1, a mounting plate 3, a support column 4, a drum 6, an inner cylinder 12, a partition plate 10, a driving gear 16, a driven gear 18 and an intermittent driving device , the upper part of the base plate 1 is fixedly connected to a pair of mounting plates 3 arranged parallel to each other, a pair of supporting columns 4 arranged in parallel to each other are arranged between the pair of mounting plates 3, and the axis of the supporting columns 4 is arranged perpendicular to the mounting plate 3, Both ends of the support column 4 are respectively fixedly connected with a rotating column 5, and the rotating column 5 is rotatably connected with the mounting plate 3. A drum 6 is placed on the upper side of the rotating column 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com