Fresh tea leaf grading machine

A classifier, tea fresh leaf technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problem of incomplete screening, etc., to achieve the effect of alleviating seasonal labor force, high efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

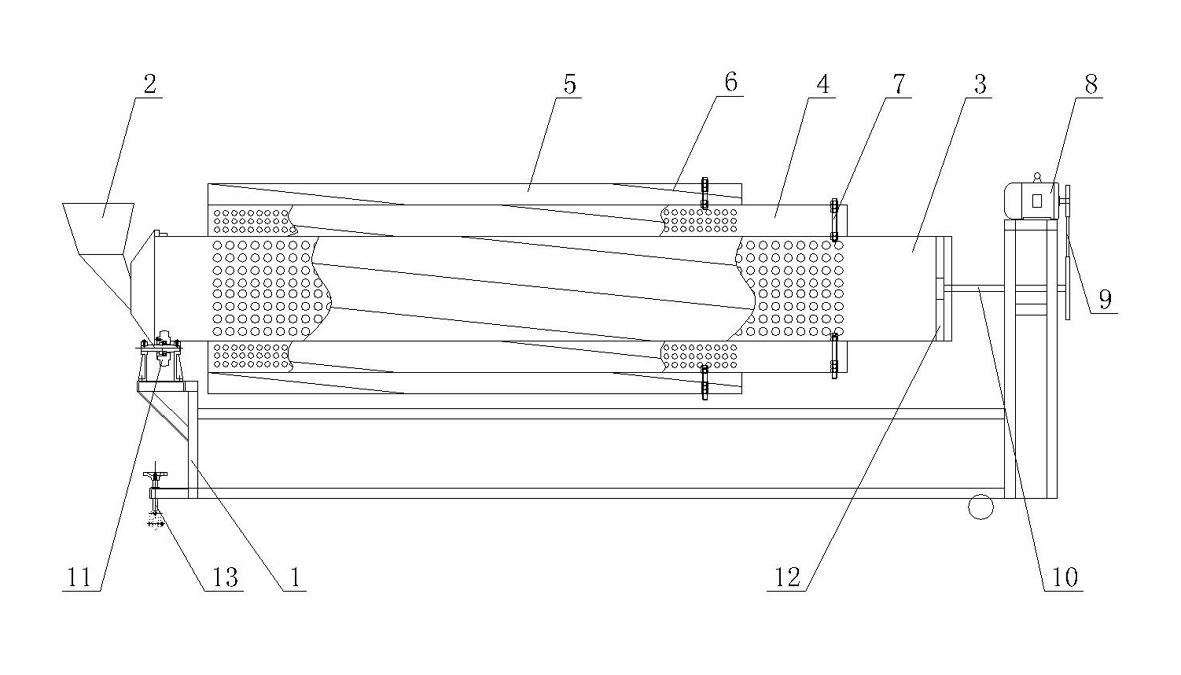

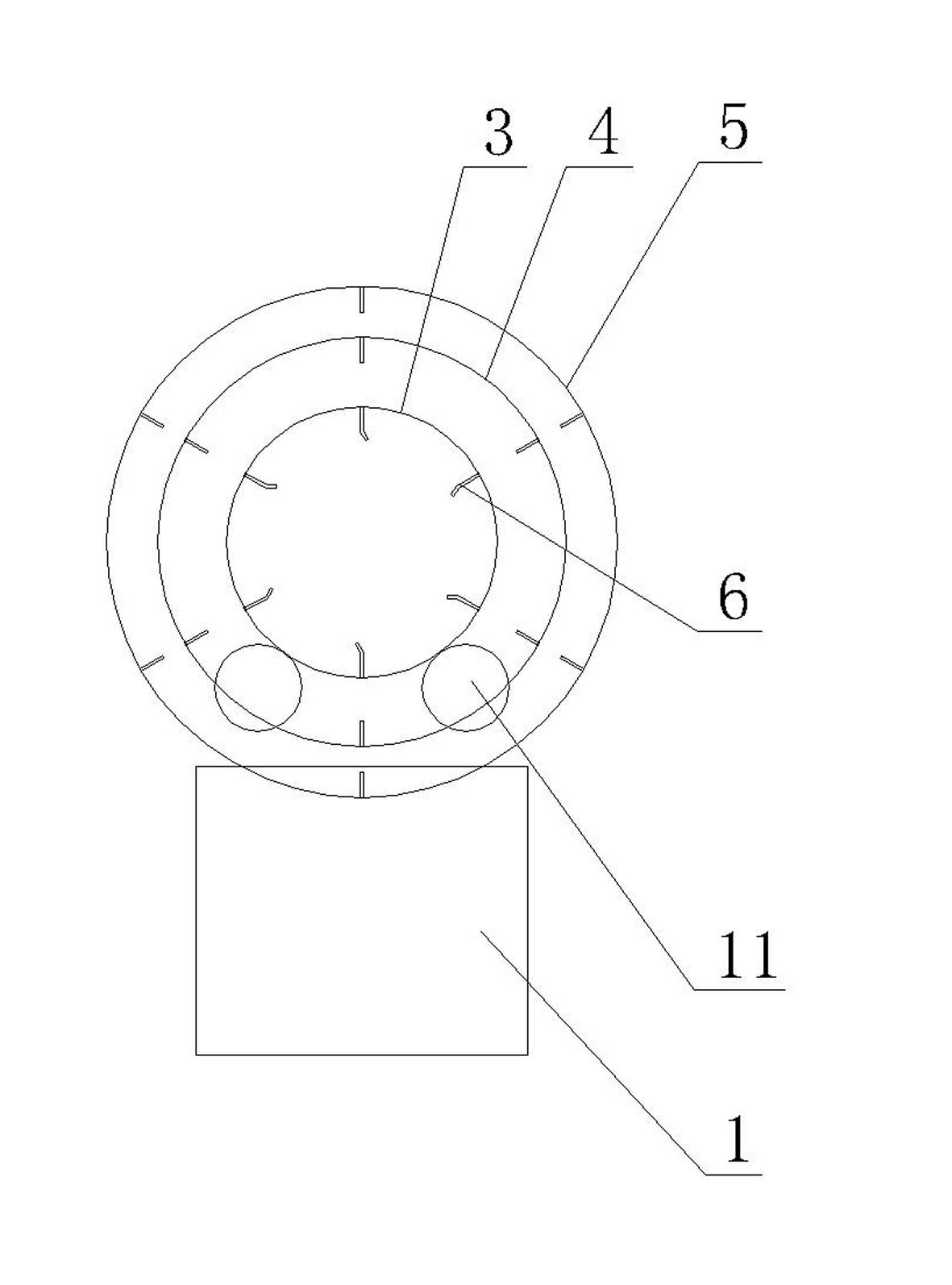

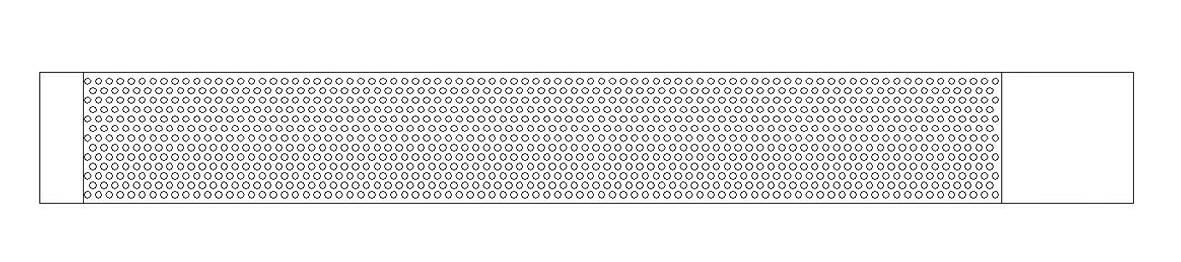

[0027] Such as figure 1 , 2 , 3 and 4, a fresh tea leaf classifier comprises a frame 1, a feed hopper 2, a power unit and a screening device, and the screening device comprises several coaxial rotating sieve cylinders, and the sieve cylinder comprises a central sieve Cylinder 3 and outer sieve cylinder 4, outer sieve cylinder 4 is coaxially provided with outer cylinder 5, center sieve cylinder 3, outer sieve cylinder 4 and inner wall of outer cylinder 5 are arranged with several spiral material guide ribs 6, center sieve cylinder 3. The outer screen cylinder 4 and the outer cylinder 5 are fixedly connected by a double-ended screw 7, and the double-ended screw 7 is installed between the central screen cylinder 3 and the outer screen cylinder 4 and between the outer screen cylinder 4 and the outer cylinder 5. The two ends of the head screw rod 7 are fixed on the corresponding screen cylinder and the outer cylinder with fastening nuts. Such as image 3 and 4 As shown, the ape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com