Method for carrying out classification magnetic separation according to particle sizes of quartz sand, and magnetic separator thereof

A magnetic separator and quartz sand technology, which is applied in the field of quartz sand treatment, can solve the problems of high cost of large-scale magnetic separators, difficulties in small and medium-sized enterprises, and difficulty in meeting the requirements for iron removal by small-scale magnetic separators, so as to improve the efficiency of iron removal , Improve the efficiency of iron removal, and improve the effect of magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means realized by the present invention, the novel features created, the purpose achieved and the effects achieved clearly understood, the present invention will be further described below in conjunction with specific illustrations.

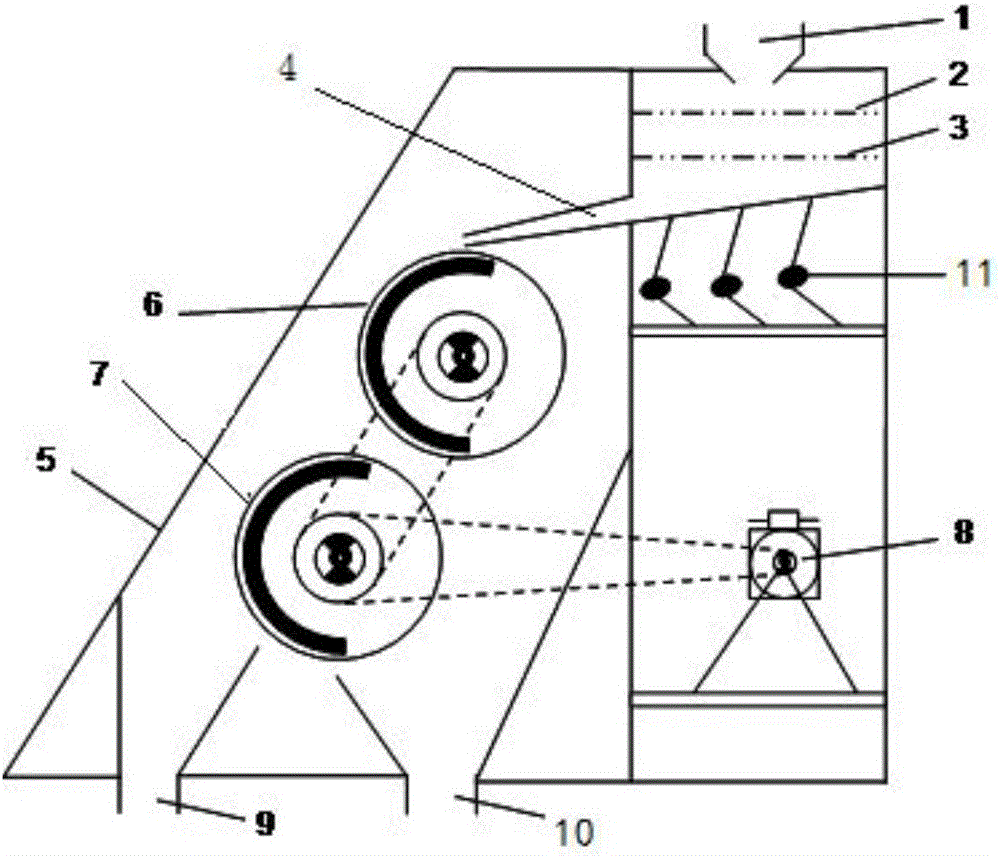

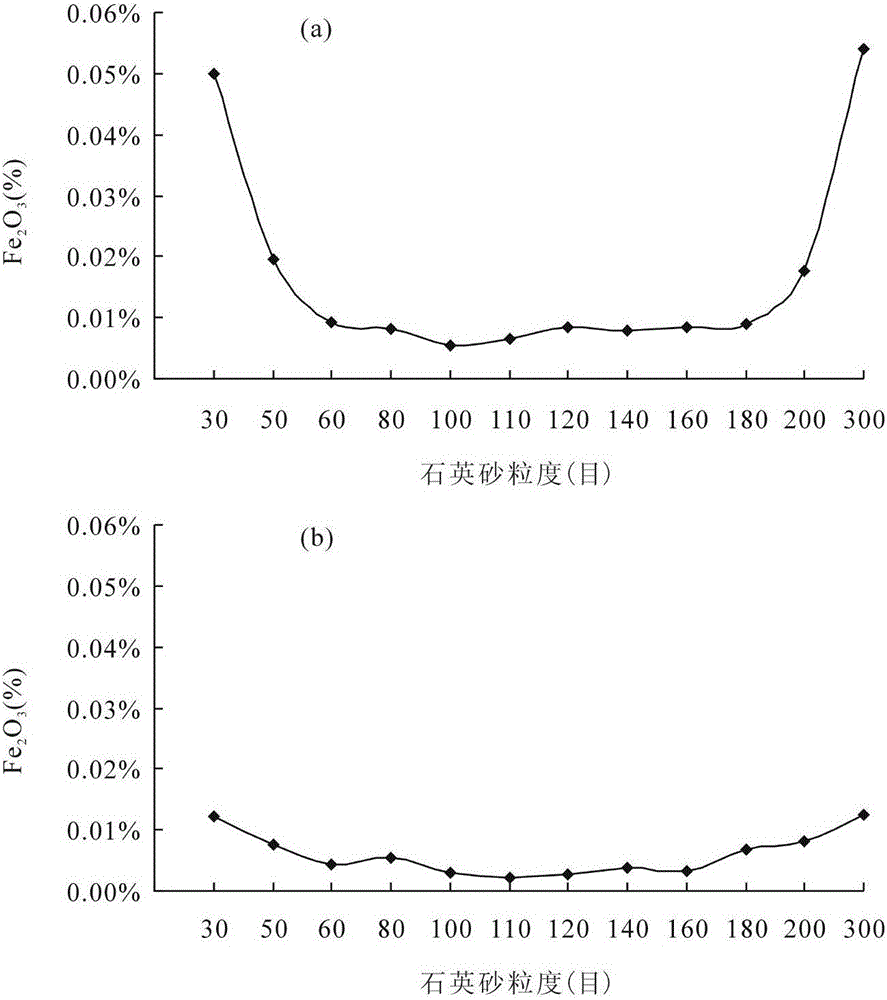

[0032] A method for classifying and magnetically separating quartz sand according to its particle size, comprising the following steps: first crushing the quartz stone; then using a sieve to classify and screen the quartz sand, the size of the primary sieve is 60 mesh, and the size of the secondary sieve is 60 mesh. The size is 180 mesh; then, the three types of quartz sand with different particle sizes after classification and screening are respectively input into three sets of magnetic separators for magnetic separation. The three sets of magnetic separators are all magnetic separators with two magnetic cylinders. The surface magnetic field strengths of the two magnetic cylinders corresponding to the quartz ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com