System for removing iron in iron-containing zinc sulfate solution

A technology of zinc sulfate solution and iron removal treatment, which is applied in the fields of chemical industry and metallurgy to achieve the effects of improving iron removal efficiency and equipment utilization rate, improving recovery rate, and increasing economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

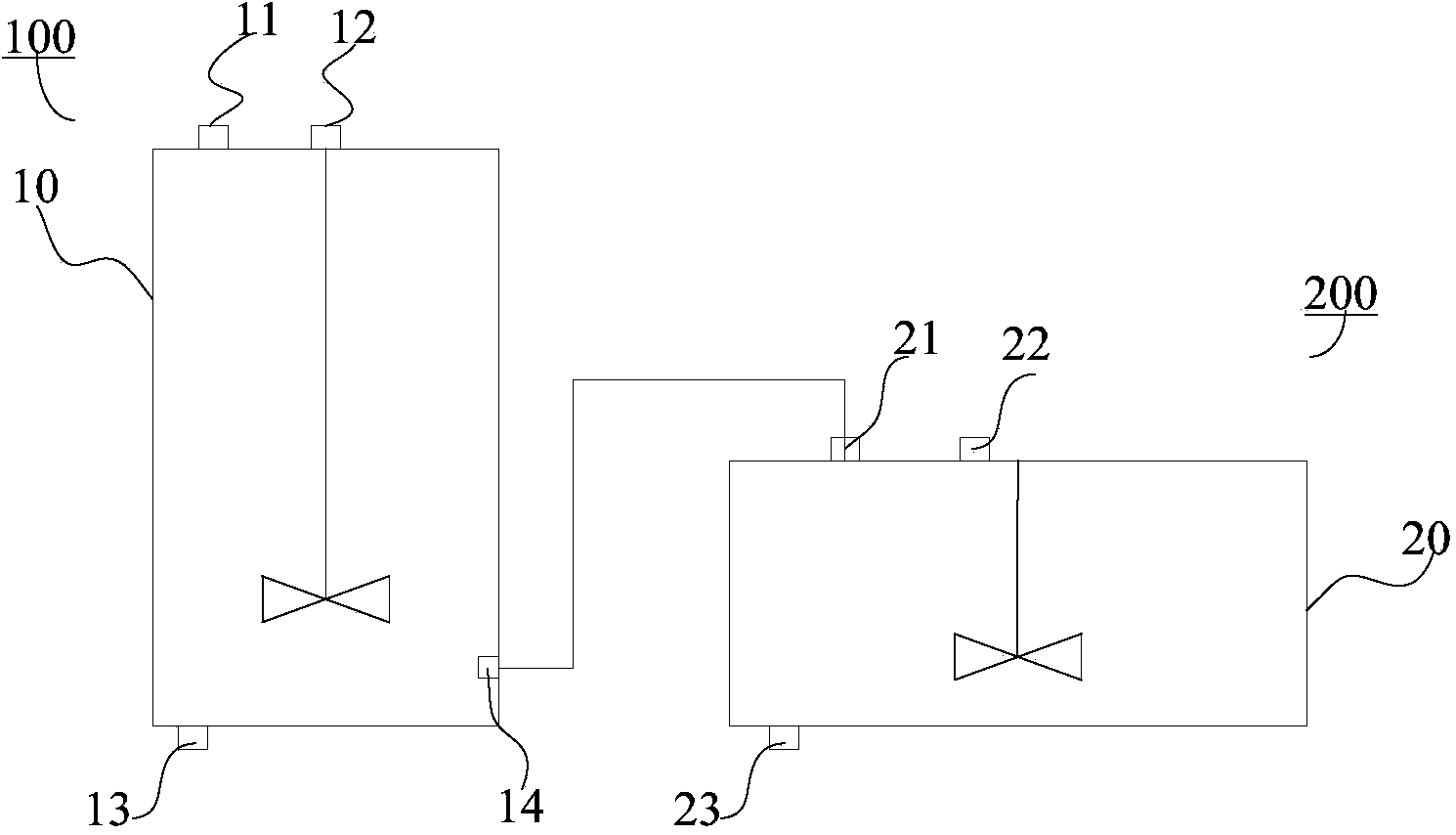

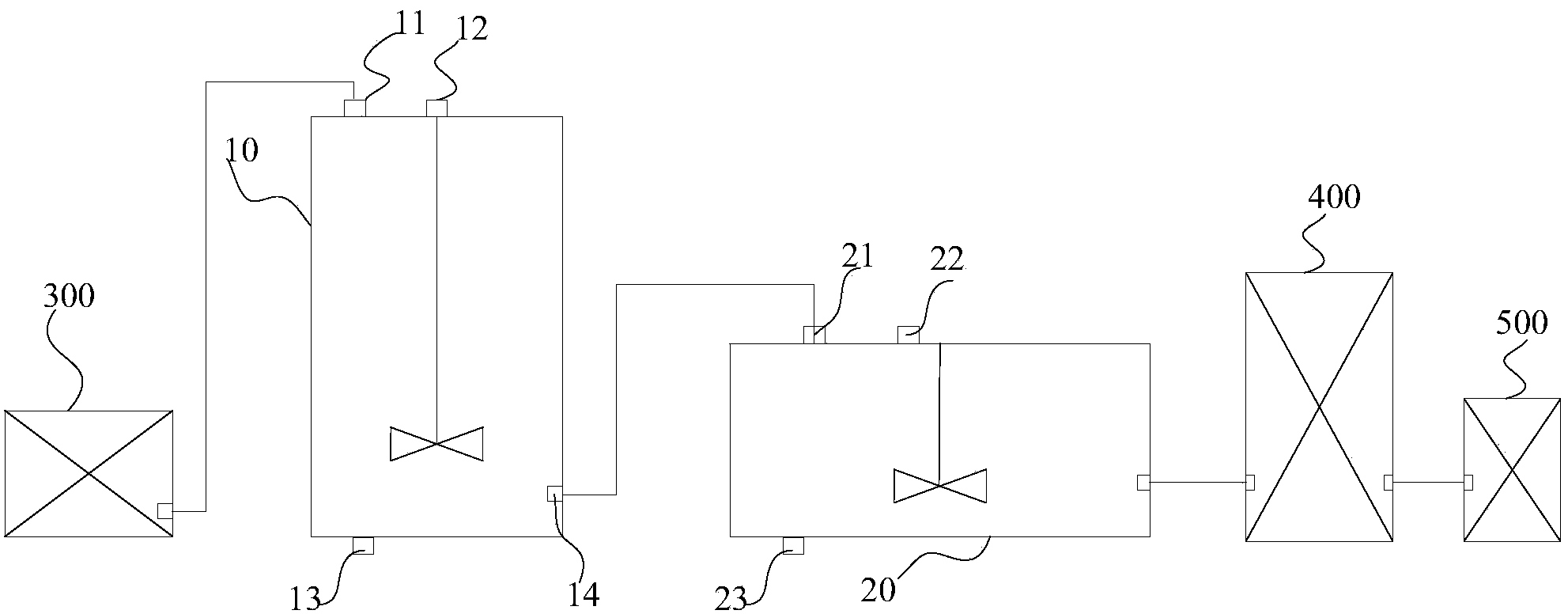

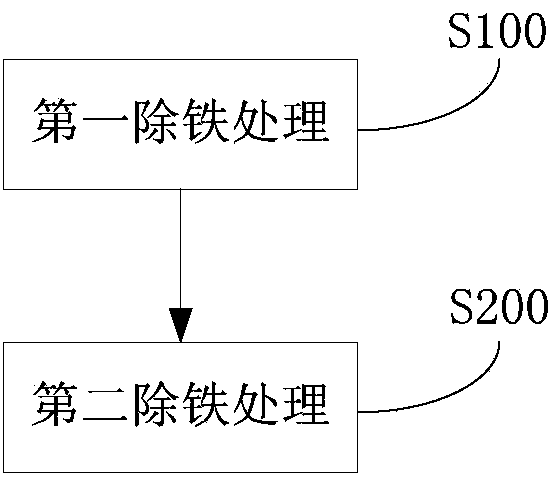

Image

Examples

Embodiment

[0059] According to the embodiment of the present invention, the iron-containing zinc sulfate solution is processed by a system for removing iron from the iron-containing zinc sulfate solution:

[0060] Wherein, the iron-containing zinc sulfate solution is the solution after zinc smelting and indium precipitation.

[0061] at 1m 3 Vertical reactor and 3m 3 In a horizontal reactor, 1m 3 Add iron-containing zinc sulfate solution at a flow rate of / h, the solution contains 100g / L of zinc and 30g / L of iron (as Fe 2+ meter), the pH value is 3, and the reaction temperature is maintained at 185°C. The iron-precipitated solution is flashed, filtered and washed to obtain iron-containing products (precipitation) and iron-precipitated liquid (filtrate), and the iron-precipitated liquid is returned to the system for circulation use.

[0062] The iron oxide-containing product is determined to contain iron 60-68%, zinc <0.5%, and sulfur <0.8%, which can be sold as cement or iron ore or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com