Powder de-ironing separator

An iron remover and powder technology, which is applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of troublesome cleaning, damage to equipment, threats to food and drug safety, etc., so as to reduce manual labor and improve iron removal efficiency. , Improve the effect of screening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

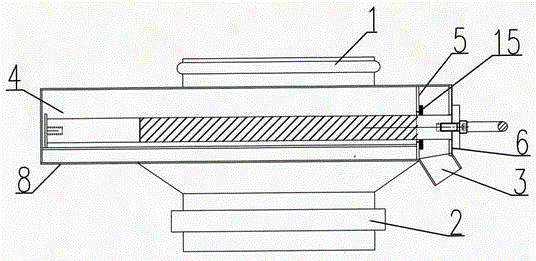

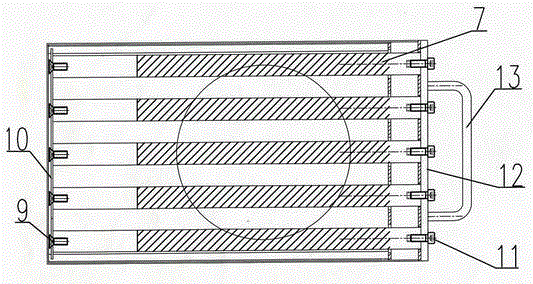

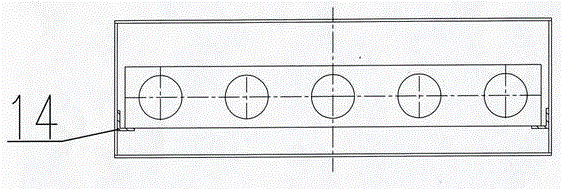

[0009] Describe embodiment in detail in conjunction with above accompanying drawing, see figure 1 As shown, the upper part of the iron remover box 4 is provided with a feed port 1, and its lower part is provided with a discharge port 2, and one end of the lower part of the iron remover box is provided with an iron discharge port 3, and the longitudinal position of the iron remover box inner cavity is used The partition 5 is divided into an iron-absorbing area and an iron-unloading area. The partition 5 is provided with a round hole for the magnetic bar 7 to pass through. There are multiple round holes. There is a horizontal guide rail 14 for the magnetic frame 8 to slide, the magnetic frame is a rectangular frame made of a magnetic bar front fixed plate 10 and a magnetic bar rear fixed plate 12, and a magnetic bar 7 fixed thereon, and the magnetic bar It is fixed on the front fixing plate 12 of the magnetic bar through the hexagonal socket head screw 11, the magnetic bar passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com