Method for efficiently deironing coal ash

A fly ash, high-efficiency technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of poor effect, large consumption of acid and alkali, low solid-phase iron yield, etc. The effect of high cycle life and iron removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

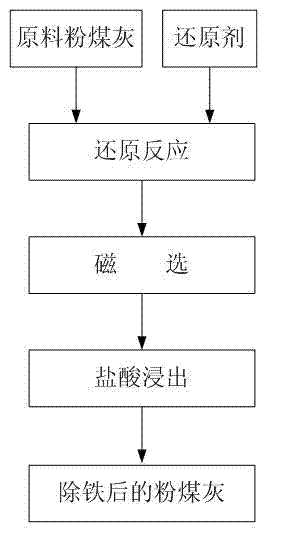

[0020] Using anthracite coal powder as the reducing agent, the process steps are as follows:

[0021] (1) The fine powder of the raw material fly ash and anthracite coal powder are subjected to reduction reaction under the condition of accompanied by nitrogen, the reaction temperature is 1000°C, the reaction time is 40 minutes, and the amount of the reducing agent is 1.5 times the stoichiometric ratio;

[0022] (2) Perform magnetic separation on the reduced fly ash three times with a magnetic field strength of 465kA m -1 ;

[0023] (3) The fly ash after magnetic separation was leached with 10% hydrochloric acid solution at a temperature of 60°C for 4 hours, filtered and dried to obtain Fe 2 o 3 Iron-removing fly ash with a content of 0.019%.

Embodiment 2

[0025] Using coke as a reducing agent, the process steps are as follows:

[0026] (1) The fine powder of the raw material fly ash and the coke are subjected to a reduction reaction under the condition of accompanied by nitrogen, the reaction temperature is 900°C, the reaction time is 50 minutes, and the amount of the reducing agent is 1.8 times the stoichiometric ratio;

[0027] (2) Perform magnetic separation on the reduced fly ash three times, with a magnetic field strength of 500kA m -1 ;

[0028] (3) The fly ash after magnetic separation was leached with 10% hydrochloric acid solution at a temperature of 60°C for 4 hours, filtered and dried to obtain Fe 2 o 3 Iron-removing fly ash with a content of 0.015%.

Embodiment 3

[0030] Using hydrogen as the reducing agent, the process steps are as follows:

[0031] (1) The fine powder of the raw material fly ash is subjected to a reduction reaction with hydrogen under the protection of nitrogen, the reaction temperature is 1100°C, the reaction time is 20 minutes, and the amount of the reducing agent is 2% of the amount of the fine powder of the raw material fly ash according to the stoichiometric ratio times;

[0032] (2) Perform magnetic separation on the reduced fly ash three times with a magnetic field strength of 650 kA m -1 ;

[0033] (3) The fly ash after magnetic separation was leached with 10% hydrochloric acid solution at a temperature of 60°C for 4 hours, filtered and dried to obtain Fe 2 o 3 Iron-removing fly ash with a content of 0.013%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com