Process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina

An ultra-high-purity and process technology, which is applied in the field of fly ash production of ultra-high-purity alumina and its comprehensive utilization, can solve the problems of difficulty in obtaining ultra-high-purity alumina, large energy consumption and resource consumption, and many process links. , to achieve the effect of high iron removal efficiency, large energy consumption and resource consumption, and many process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

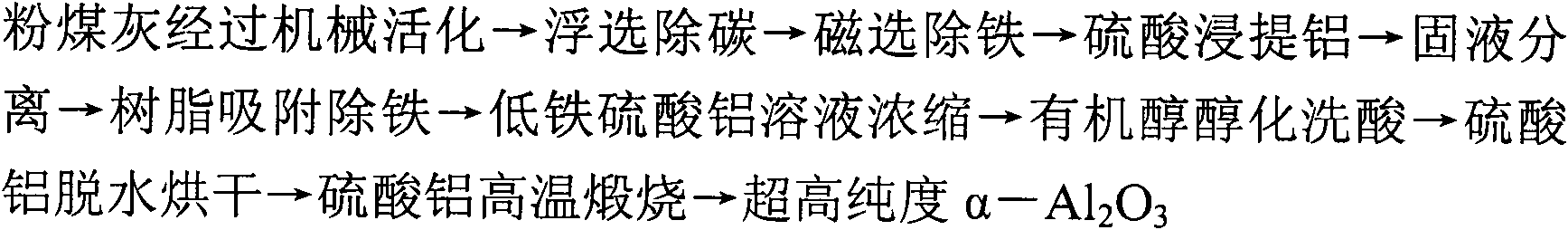

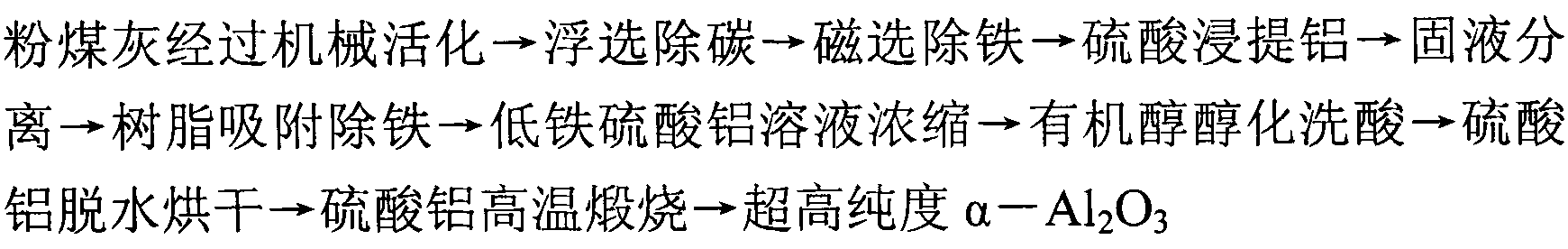

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: raw material fly ash is composed of: Al 2 o 3 Content 37.7%, Fe 2 o 3 Content 4.38%, CaO content 3.74%, MgO content 0.54%, SiO 2 The content is 49.9%, and the loss on ignition is 1.92%. The raw fly ash can also use other components and their corresponding amounts.

[0050] Mill the fly ash in a ball mill for 1 hour to perform mechanical activation; add water according to the mass ratio of fly ash to water of 1:3, fully stir, remove unburned black through flotation; and remove iron oxide through magnetic separation; The fly ash residue after flotation carbon and magnetic separation of iron and concentrated sulfuric acid are made into a mixed solution with a sulfuric acid concentration of 40%. The solid-liquid ratio of the fly ash and the mixed solution is controlled to be 1:8. Heating and pressurizing the reaction for 3 hours, the highest temperature of the reaction is 240 °C; after the reaction cools down, add water according to the mass ratio of fly ...

Embodiment 2

[0056] Embodiment 2: Press the obtained aluminum sulfate crude liquid into a resin column equipped with JK008 macroporous cationic resin with a corrosion-resistant pump to remove iron. The treatment temperature is 90° C., and the flow rate of the aluminum sulfate crude liquid is 2 times the volume of the resin during processing. / h to obtain a low-iron aluminum sulfate solution.

[0057] When the macroporous cationic resin is adsorbed and saturated, the resin can recover its adsorption capacity through elution and regeneration. The elution conditions are as follows: the eluent adopts hydrochloric acid with a concentration of 8%, the elution temperature is 30° C., and the flow rate of hydrochloric acid is 2 times the resin volume / h, a total of 1 times the resin volume of hydrochloric acid was used for elution; the concentration of 8% hydrochloric acid was used for regeneration, the temperature was 20°C, and the flow rate of hydrochloric acid was 2 times the resin volume / h, a tot...

Embodiment 3

[0060] Embodiment 3: with the fly ash in embodiment 1, ball mill 3h in ball mill, carry out mechanical activation; According to the mass ratio of fly ash and water is 1: 2, add water, fully stir, remove unburned net through flotation black; and then remove iron oxide by magnetic separation; make a mixed solution with a sulfuric acid concentration of 80% from the fly ash residue after flotation carbon and magnetic iron separation and concentrated sulfuric acid, and control the solid-liquid concentration of fly ash and the mixed solution Ratio of 1:6, heating and pressurizing reaction in acid-resistant reaction equipment for 5h, the highest temperature of the reaction is 240°C; The filter cake was obtained by filtration, and washed with water with a mass ratio of fly ash to water of 1:2 to obtain a crude aluminum sulfate solution with a pH value of 1. The extraction rate of aluminum analyzed was 74%.

[0061] Press the obtained aluminum sulfate crude liquid into a resin column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com