Material breaking equipment for brick making

A material crushing and equipment technology, applied in the field of brick-making material crushing equipment, can solve the problems of dust pollution in the workshop, brick-making quality, easy blockage of red brick materials, poor quality, etc., to improve iron removal efficiency, good crushing effect, prevent The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

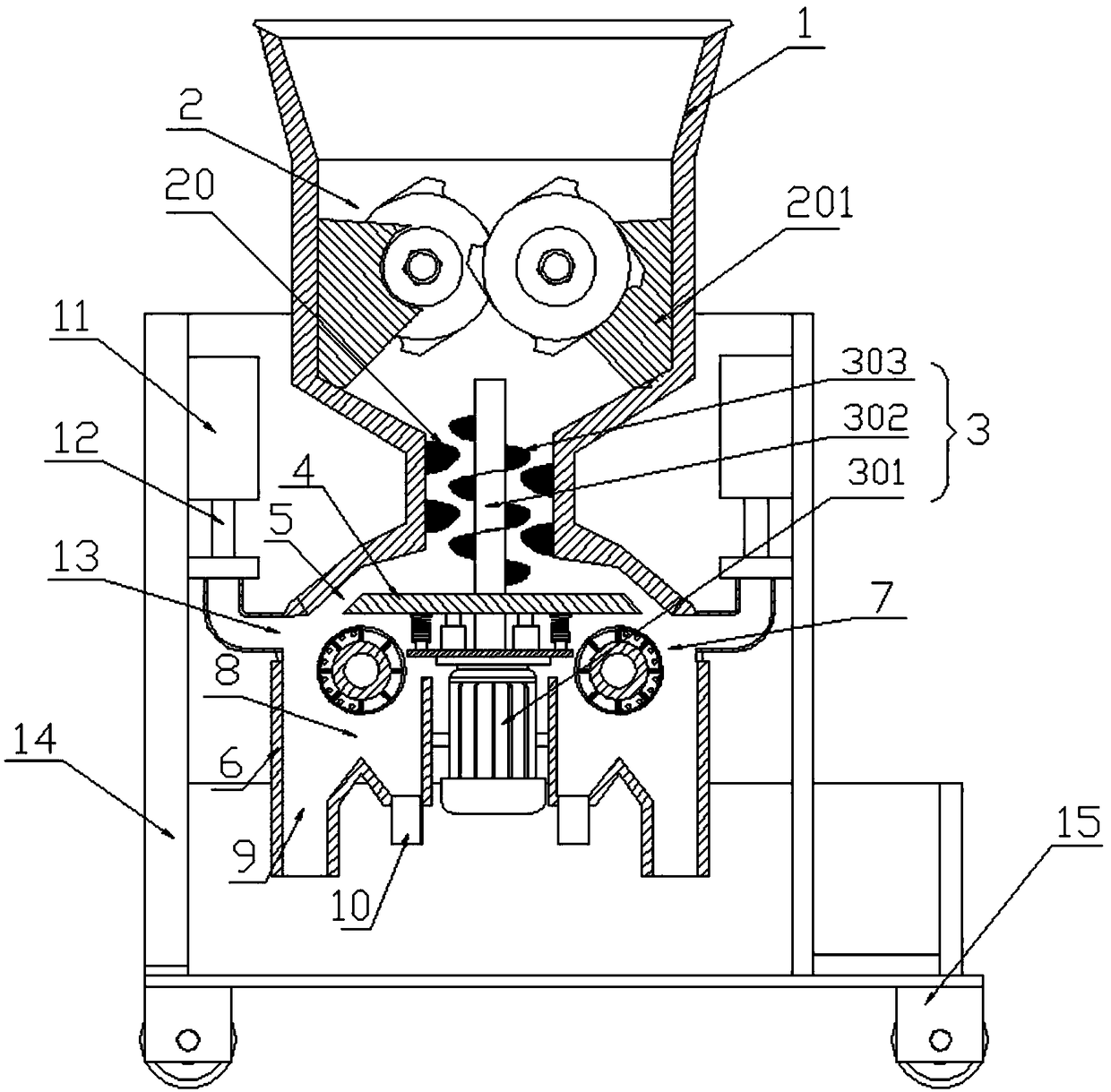

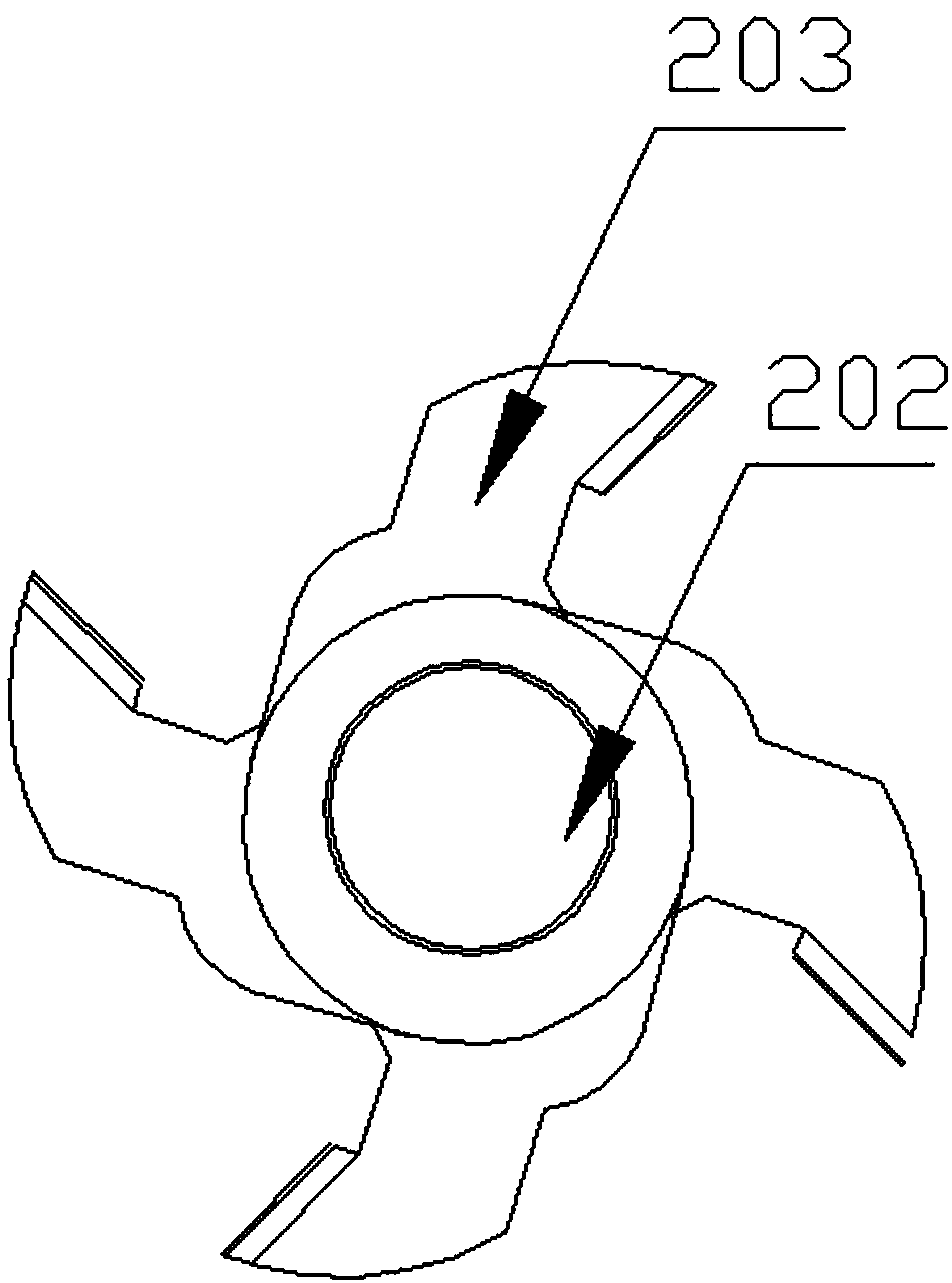

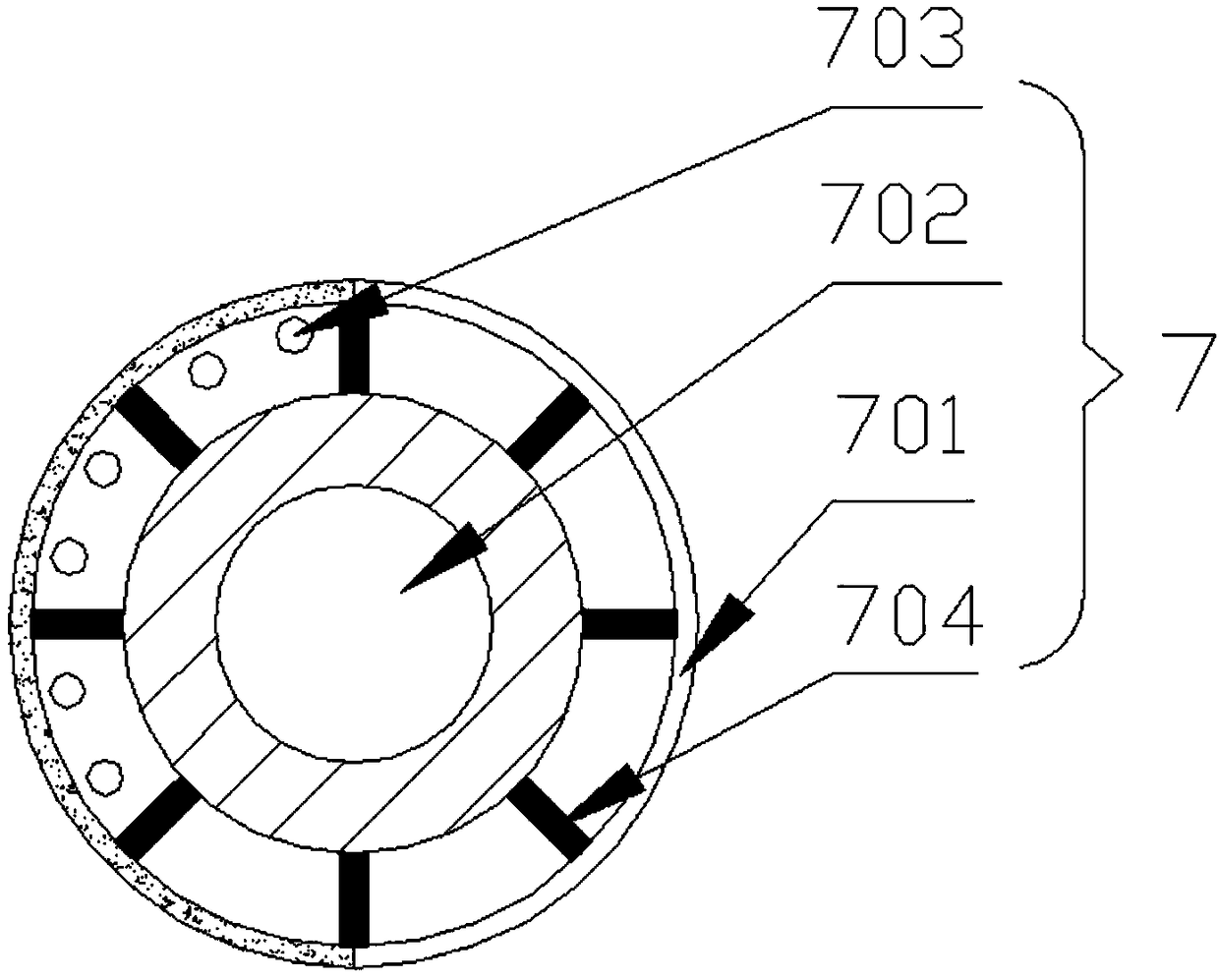

[0023] Such as Figure 1-6 As shown, the specific structure of the present invention is: a material crushing equipment for brick making, including a casing 1; the upper part of the casing 1 is a feeding bin, the middle part is provided with a crushing mechanism 2, and the lower part of the outlet is an outer splayed structure The lower end outlet of the casing 1 is provided with a stirring assembly 3, and the stirring assembly 3 is composed of a motor 301, a stirring shaft 302 and a stirring roller 303; the crushing roller nail 20 is fixed in the casing 1, and the crushing roller Nails 20 and stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com