Mixed flora and application thereof in iron removal and whitening for kaolin

A technology of mixing flora and kaolin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

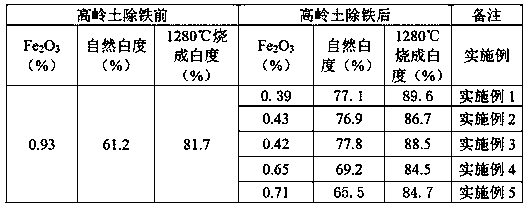

Image

Examples

Embodiment 1

[0056] 1. Preparation of mixed flora bacterial solution:

[0057] Iron-reducing bacteria RBFL, iron-reducing bacteria RBFL3 and iron-reducing bacteria FeRB-FL1404 were respectively activated and expanded to obtain corresponding bacterial liquids, and the concentration of viable bacteria in each bacterial liquid was 10 7 CFU / ml-10 9 CFU / ml;

[0058] 2. Prepare the above-mentioned bacteria solution according to the volume ratio of iron-reducing bacteria RBFL, iron-reducing bacteria RBFL and iron-reducing bacteria FeRB-FL1404 at a ratio of 1:2:1.6 to prepare a mixed bacterial solution;

[0059] 3. Kaolin is sieved to a particle size of 200-400 mesh, and water is added to prepare kaolin slurry A with a mass fraction of 10%;

[0060] 4. Add 1.2% molasses of pulp A quality, 1.2% peptone of pulp A quality, 0.006% pulp A quality Tween 80 and 0.008% pulp A quality MgSO to the above pulp A 4, Prepared into pulp B;

[0061] 5. Add the bacterial solution prepared in step (2) to the ...

Embodiment 2

[0066] 1. Preparation of mixed flora bacterial solution:

[0067] Iron-reducing bacteria RBFL, iron-reducing bacteria FeRB-FL1404 and Geobacter bremensis Straub and Buchholz-Cleven (ATCC BAA-607) were respectively activated and expanded to obtain corresponding bacterial liquids, and the concentration of viable bacteria in each bacterial liquid was 10 7 CFU / ml-10 9 CFU / ml;

[0068] 2. Prepare the above-mentioned bacterial liquid according to the volume ratio of iron-reducing bacteria RBFL, iron-reducing bacteria FeRB-FL1404 and Geobacter bremensis Straub and Buchholz-Cleven (ATCC BAA-607) at a ratio of 3:6:2 to prepare a mixed bacterial liquid ;

[0069] 3. The rest of the operating steps (steps 3-8) are the same as in Example 1.

Embodiment 3

[0071] 1. Preparation of mixed flora bacterial solution:

[0072] Iron-reducing bacteria FeRB-FL1404, iron-reducing bacteria FL-H1 and Achromobacter (CCTCC AB 206571) were respectively activated and expanded to obtain corresponding bacterial liquids, and the concentration of viable bacteria in each bacterial liquid was 10 7 CFU / ml-10 9 CFU / ml;

[0073] 2. Prepare the above-mentioned bacterial solution according to the volume ratio of iron-reducing bacteria FeRB-FL1404, iron-reducing bacteria FL-H1 and Achromobacter (CCTCC AB206571) at a volume ratio of 5:8:2 to prepare mixed bacteria liquid;

[0074] 3. The rest of the operating steps (steps 3-8) are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com