Hyperfine high-gradient magnetic separator

A high-gradient magnetic separator and ultra-fine technology, applied in the field of beneficiation machinery, can solve the problems of inability to meet high production capacity requirements, failure to meet the requirements of fine iron removal, and high tailings grade, and to simplify on-site grading operations and iron removal efficiency. The effect of high and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

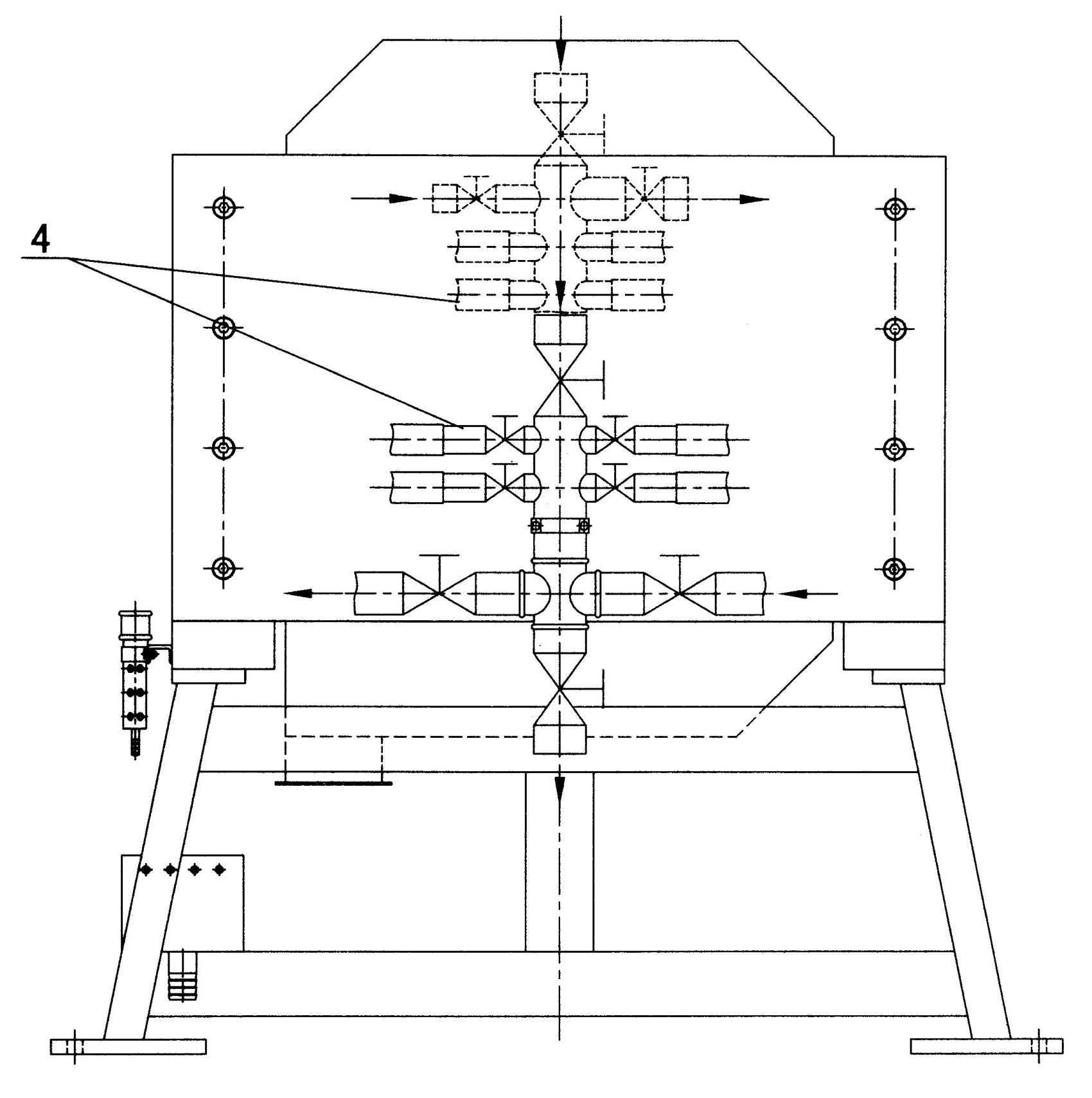

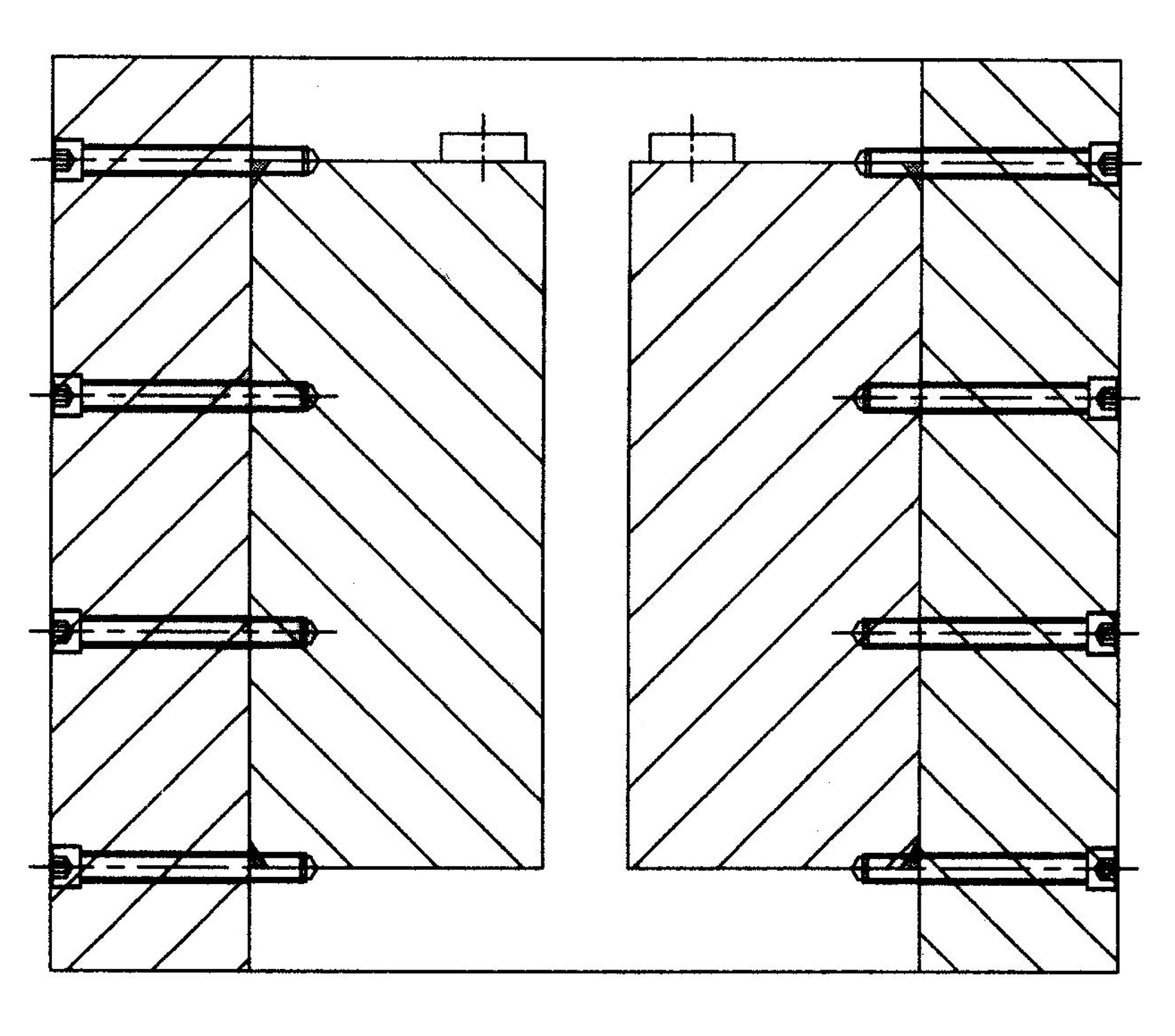

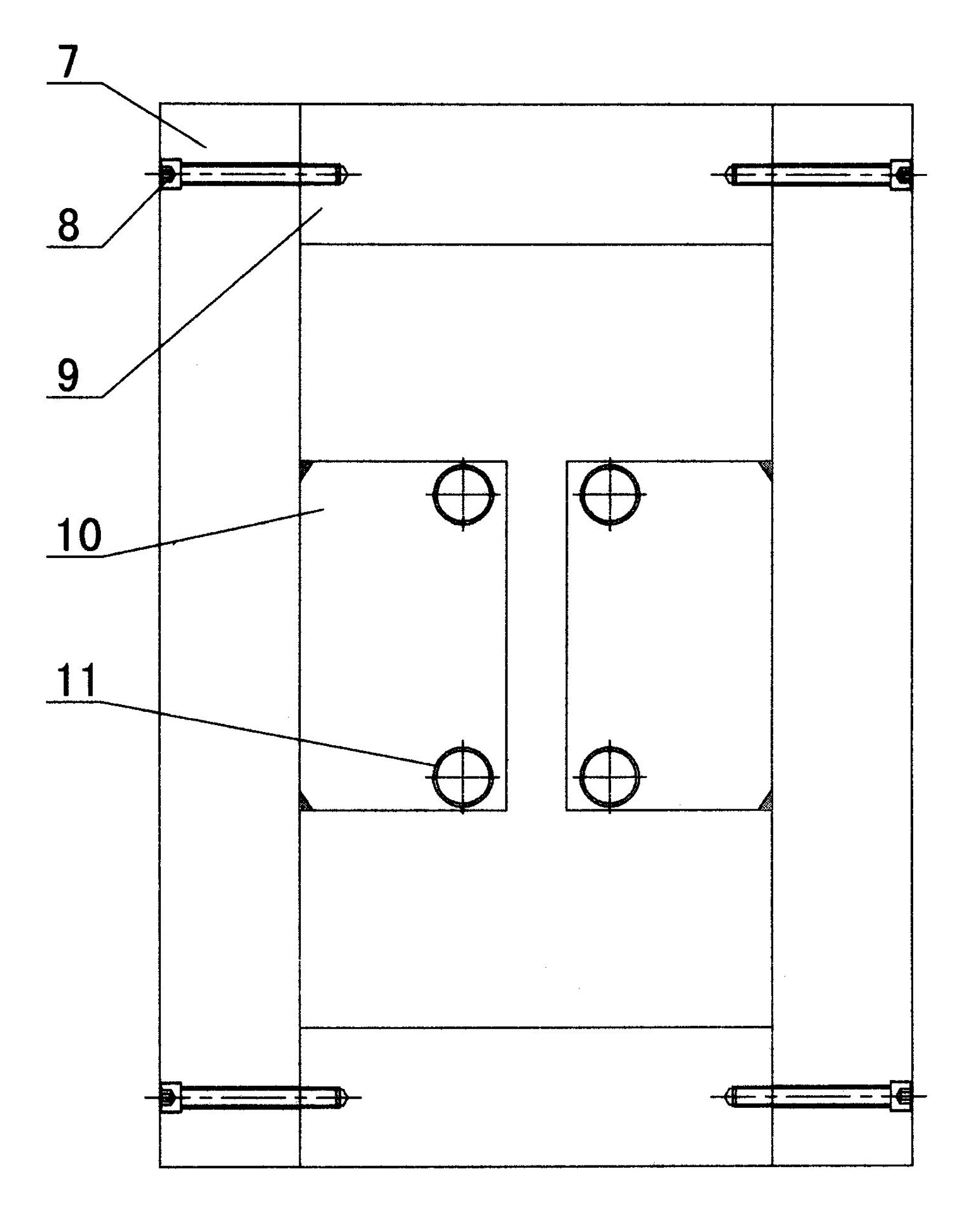

[0026] Depend on Figure 1 to Figure 12 It can be seen that the present invention includes the main equipment part and the rectification control cabinet part, wherein:

[0027] The main equipment part includes a main body support 1, a magnetic yoke 2 arranged on the upper part of the main body support 1, an excitation coil 3 arranged around the magnetic yoke 2, and a magnetic medium box 5 arranged in the central gap inside the magnetic yoke 2, wherein the magnetic medium box 5 The upper part of the connection vibration mechanism 6;

[0028] The outer sides of the yoke 2 are provided with a pipeline system 4 for entering and exiting pulp and flushing water, which includes pneumatic valves, solenoid valves 46 and ball valves 49, and the pipeline system 4 is connected to the magnetic medium box 5;

[0029] The rectification control cabinet part includes a control system for controlling the excitation and de-excitation of the excitation coil 3, and controlling the action and rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com