Walking small electric hoister suitable for transferring materials between reverse building method floors

An electric lifting and floor-to-floor technology, which is applied in the direction of trolley cranes, lifting equipment braking devices, cranes, etc., can solve problems such as long construction period, low resource utilization rate, and lack of material lifting machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

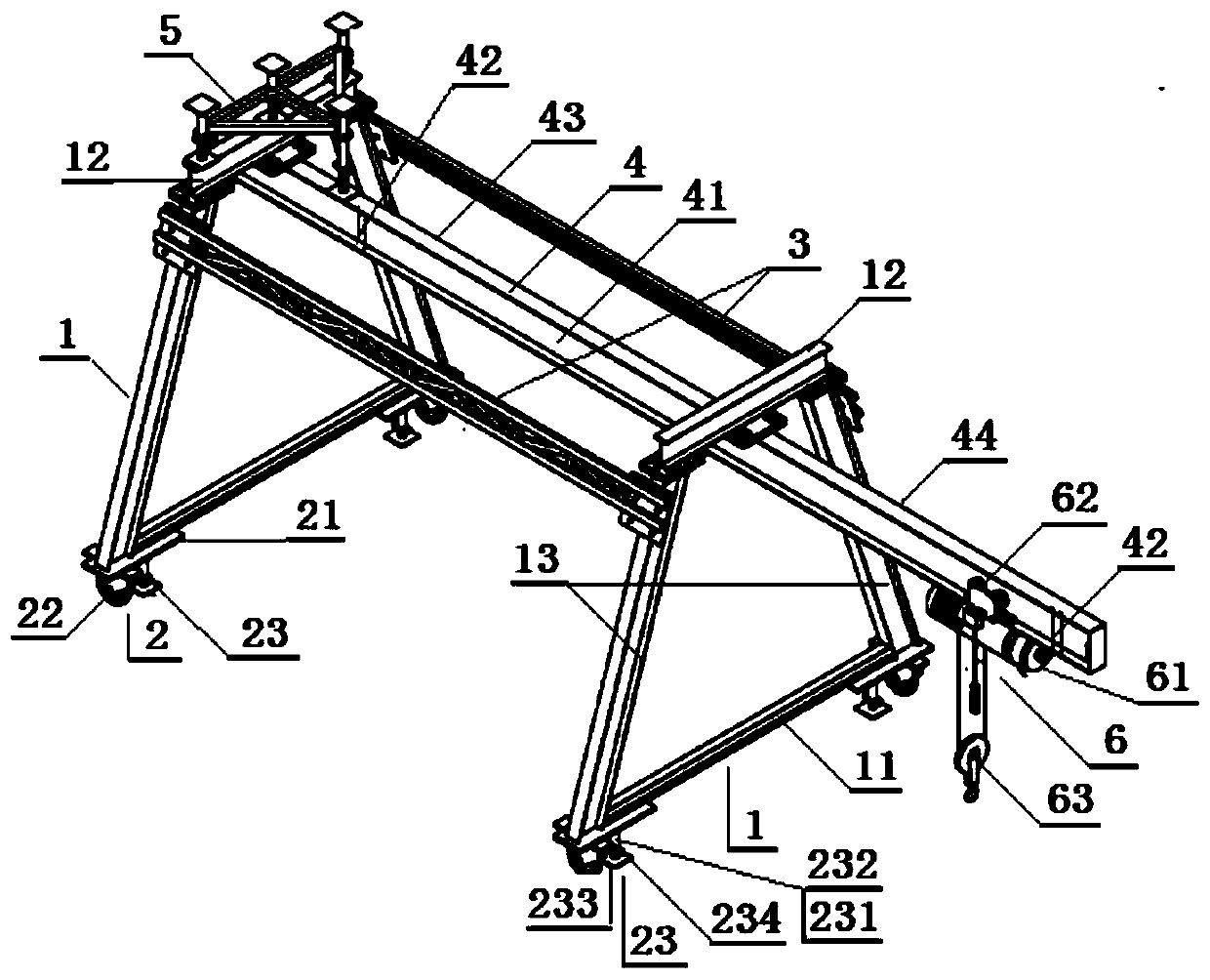

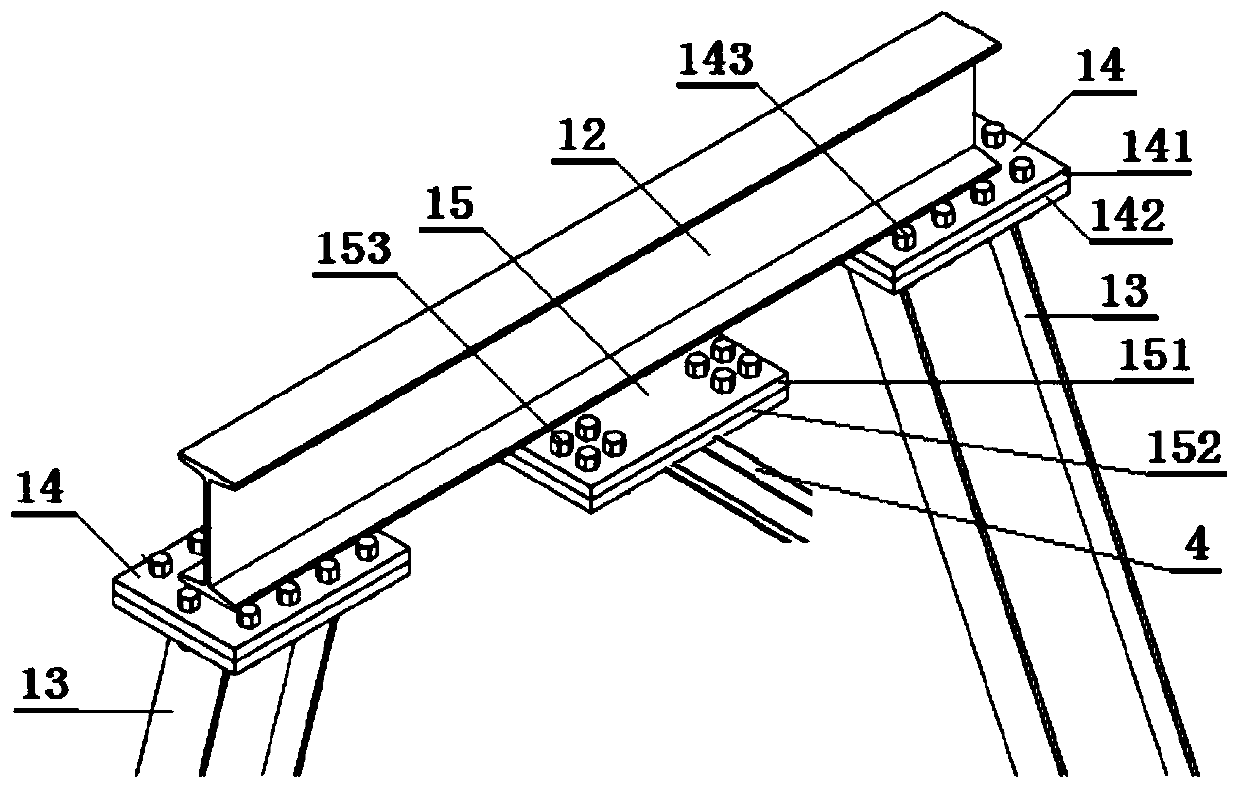

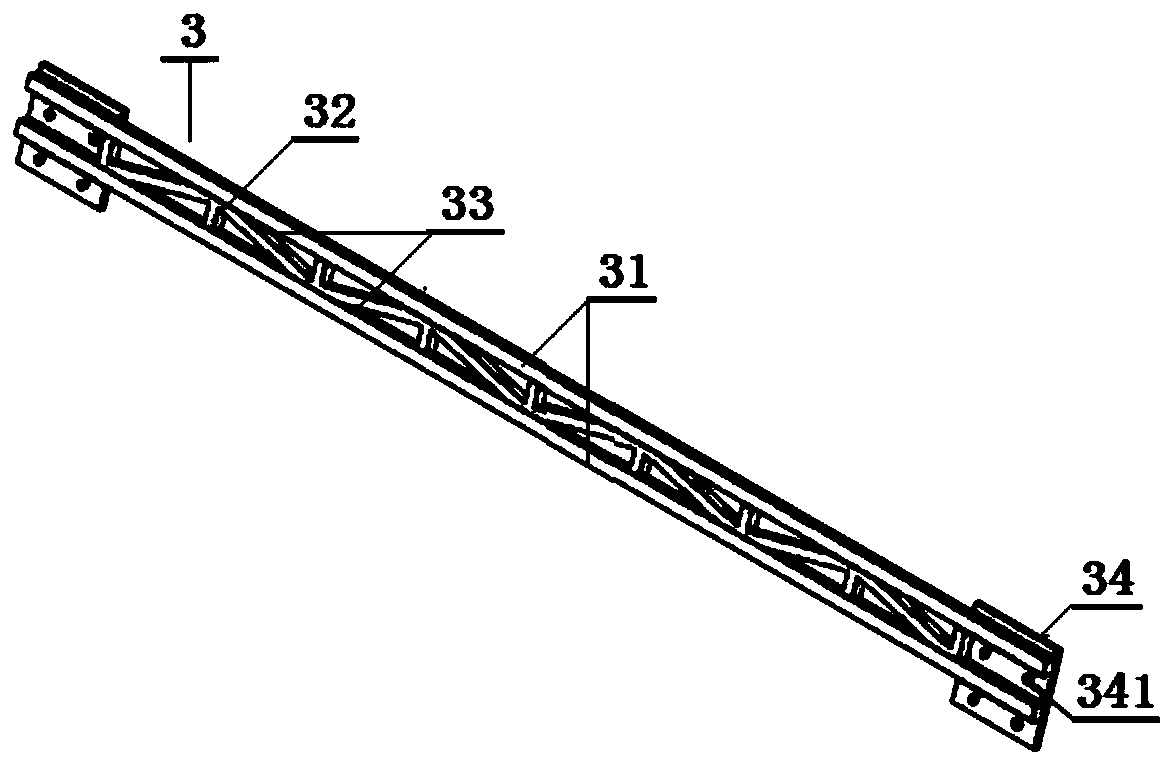

[0038] exist Figure 1 to Figure 5 Among them, the walkable small electric hoist suitable for transferring materials between floors in the reverse method of the present invention has a main body including a front and rear column frame 1, a bottom support assembly 2, an anti-overturning truss 3, a crane beam 4, a reaction force anti-overturning mechanism 5 and Walking lifting mechanism 6, wherein:

[0039] The main body of the front and rear column frame 1 is in the shape of an isosceles trapezoid, including a bottom interconnecting beam 11 made of I-shaped steel serving as the lower bottom of the trapezoid, and an upper beam 12 made of I-shaped steel serving as the upper bottom of the trapezoid. The left and right slanting columns 13, which are made of I-shaped steel and serve as the two waists of the trapezoid, are assembled by bolts to the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com