Method for co-production of aluminum potassium sulfate and gypsum through activated clay production mother liquid

A technology of activated clay and mother liquor, which is applied in chemical instruments and methods, multi-stage treatment of water/sewage, aluminum sulfate, etc., can solve the problems of high cost and long cycle of producing alum, and achieve increased economic benefits of enterprises, short cycle, and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

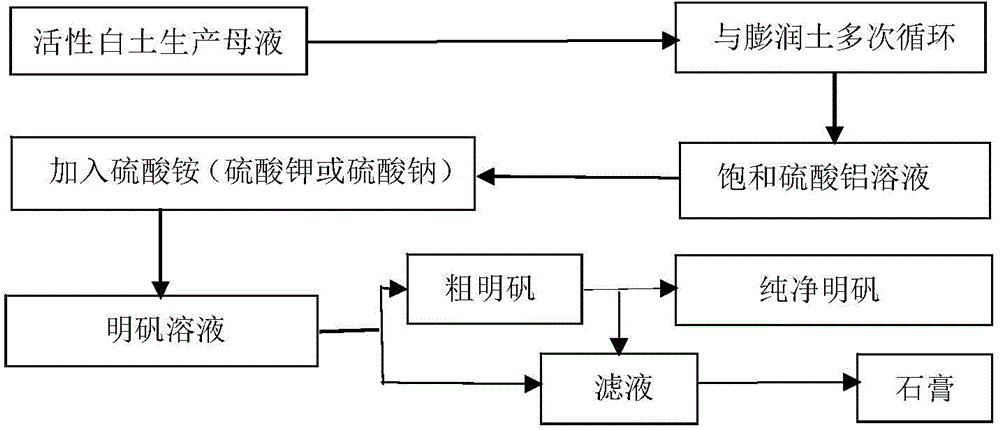

[0026] A kind of method utilizing activated clay to produce mother liquor to co-produce ammonium alum, gypsum, comprises the following steps:

[0027] S1: The activated clay production mother liquor is mixed with bentonite and then heated to dissolve the aluminum sulfate in the bentonite in the production mother liquor, and then the activated clay production mother liquor with increased aluminum sulfate concentration is circulated and mixed with the newly added bentonite, and the mother liquor is recycled according to this method 3 Second, control the temperature of dissolving aluminum sulfate to 95°C until the aluminum sulfate dissolved in the production mother liquor reaches saturation; control the temperature of the prepared saturated aluminum sulfate production mother liquor at 75°C, adjust the pH value to 2.5 with ammonium bicarbonate, add sulfuric acid Ammonium reacts to form ammonium alum, and the amount added makes NH 4 + :Al 3+ :SO 4 2- The molar concentration rat...

Embodiment 2

[0030] A kind of method utilizing activated clay to produce mother liquor co-production potassium alum, gypsum, comprises the following steps:

[0031] S1: The activated clay production mother liquor is mixed with bentonite and heated to dissolve the aluminum sulfate in the bentonite in the production mother liquor, and then the activated clay production mother liquor with increased aluminum sulfate concentration is circulated and mixed with the newly added bentonite, and the mother liquor is recycled according to this method 4 Second, control the temperature of dissolving aluminum sulfate to 100°C until the aluminum sulfate dissolved in the production mother liquor reaches saturation; control the temperature of the prepared saturated aluminum sulfate production mother liquor at 85°C, and use activated clay waste acid mother liquor with a pH of 1.5 to adjust the pH Value is 4, adding potassium sulfate reacts to generate potassium alum, and the added amount makes K + :Al 3+ :S...

Embodiment 3

[0034] A kind of method utilizing activated clay to produce mother liquor to co-produce sodium alum, gypsum, comprises the following steps:

[0035] S1: The activated clay production mother liquor is mixed with bentonite and then heated to dissolve the aluminum sulfate in the bentonite in the production mother liquor, and then the activated clay production mother liquor with increased aluminum sulfate concentration is circulated and mixed with the newly added bentonite, and the mother liquor is recycled according to this method 3 Second, control the temperature of dissolved aluminum sulfate to 98°C until the aluminum sulfate dissolved in the production mother liquor reaches saturation; control the temperature of the prepared saturated aluminum sulfate production mother liquor at 80°C, use ammonium bicarbonate to adjust the pH value to 3.2, add sulfuric acid Sodium reacts to generate sodium alum, and the added amount makes Na + :Al 3+ :SO 4 2- The molar concentration ratio i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com