Sodium bentonite and double sodium modifying method for sodium bentonite

A technology of sodium-based bentonite and calcium-based bentonite, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of uneven sodium-based and insufficient sodium-based effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

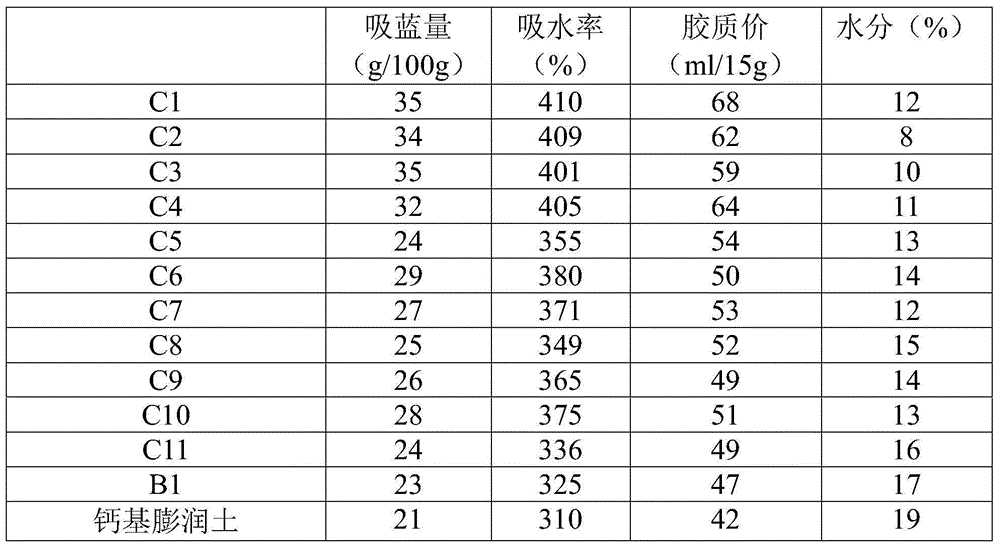

Image

Examples

preparation example 1

[0029] 1) At 60°C, soak the silica gel in an aqueous solution of sodium carbonate (containing 25-30% by weight of sodium carbonate) for 3.5h, and then filter to obtain a sodium-salt-modified silica gel (measured by weighing method). contains 8% by weight of sodium carbonate);

[0030] 2) Mix microcrystalline cellulose, sodium salt modified silica gel (300 mesh in particle size), expanded vermiculite (300 mesh in particle size), ammonium borate, magnesium oxide and polyacrylamide (7 million weight average molecular weight) Prepare additive A1; wherein, the weight ratio of sodium salt-modified silica gel, microcrystalline cellulose, expanded vermiculite, ammonium borate, magnesium oxide and polyacrylamide is 100:8:50:6:4:5.

preparation example 2

[0032] 1) Soak the silica gel in an aqueous sodium carbonate solution (containing 25% by weight of sodium carbonate) for 3 hours at 50° C., and then filter to obtain a sodium-salt-modified silica gel (the silica gel modified by sodium salt contains 5 % by weight of sodium carbonate);

[0033] 2) Mix microcrystalline cellulose, sodium salt-modified silica gel (300 mesh in particle size), expanded vermiculite (300 mesh in particle size), ammonium borate, magnesium oxide and polyacrylamide (4 million weight average molecular weight) Additive A2 is prepared; wherein, the weight ratio of sodium salt-modified silica gel, microcrystalline cellulose, expanded vermiculite, ammonium borate, magnesium oxide and polyacrylamide is 100:5:40:3:1:2.

preparation example 3

[0035] 1) At 70°C, soak the silica gel in an aqueous solution of sodium carbonate (containing 30% by weight of sodium carbonate) for 4 hours, and then filter to obtain a sodium-salt-modified silica gel (the silica gel modified by sodium-salt contains 10% by weight). % by weight of sodium carbonate);

[0036] 2) Mix microcrystalline cellulose, sodium salt-modified silica gel (300 mesh in particle size), expanded vermiculite (300 mesh in particle size), ammonium borate, magnesium oxide and polyacrylamide (10 million weight average molecular weight) Additive A3 is prepared; wherein, the weight ratio of sodium salt-modified silica gel, microcrystalline cellulose, expanded vermiculite, ammonium borate, magnesium oxide and polyacrylamide is 100:14:60:8:5:7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com