Preparation technology of bentonite for oil-based drilling fluid

A technology for oil-based drilling fluid and preparation process, applied in the field of bentonite modification and processing, can solve the problems of sufficient exchange of unfavorable exchangeable ions, affecting the final performance of the product, and affecting the adequacy of organicization, etc. The effect of the effect, the dispersion effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

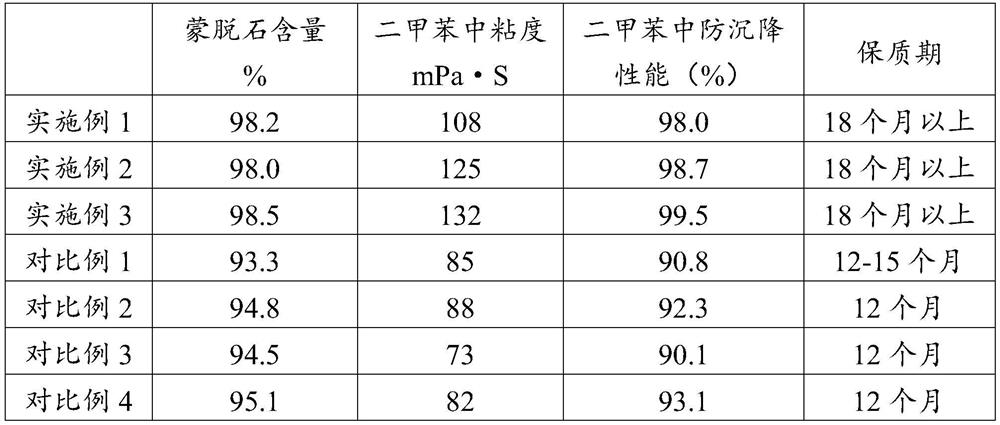

Examples

Embodiment 1

[0027] A preparation process of bentonite for oil-based drilling fluid, said process comprising the steps of:

[0028] Step S1: rough selection of raw material bentonite, pulverized to a certain particle size for subsequent use;

[0029] Step S2: pulping, adding a certain amount of water and a pulping auxiliary to the raw material bentonite in step S1 to make a slurry, and the pulping auxiliary is composed of sodium lignosulfonate and amino trihydric alcohol;

[0030] Step S3: Artificial sodiumization, adding a certain amount of sodium salt to the slurry in step S2, and sodiumizing for a period of time;

[0031] Step S4: purification;

[0032] Step S5: organic activation, add a certain amount of organic ammonium salt and activation auxiliary agent, activate the reaction for a certain period of time, the activation auxiliary agent is 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and A mixture of tungstophosphoric acid PW12;

[0033] Step S6: filtering, drying, c...

Embodiment 2

[0036] A preparation process of bentonite for oil-based drilling fluid, said process comprising the steps of:

[0037] Step S1: rough selection of raw material bentonite, pulverized to a certain particle size for subsequent use;

[0038] Step S2: pulping, adding a certain amount of water and a pulping auxiliary to the raw material bentonite in step S1 to make a slurry, and the pulping auxiliary is composed of sodium lignosulfonate and amino trihydric alcohol;

[0039] Step S3: Artificial sodiumization, adding a certain amount of sodium salt to the slurry in step S2, and sodiumizing for a period of time;

[0040] Step S4: purification;

[0041] Step S5: organic activation, add a certain amount of organic ammonium salt and activation auxiliary agent, activate the reaction for a certain period of time, the activation auxiliary agent is 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and A mixture of tungstophosphoric acid PW12;

[0042] Step S6: filtering, drying, c...

Embodiment 3

[0045] A preparation process of bentonite for oil-based drilling fluid, said process comprising the steps of:

[0046] Step S1: rough selection of raw material bentonite, pulverized to a certain particle size for subsequent use;

[0047] Step S2: pulping, adding a certain amount of water and a pulping auxiliary to the raw material bentonite in step S1 to make a slurry, and the pulping auxiliary is composed of sodium lignosulfonate and amino trihydric alcohol;

[0048] Step S3: Artificial sodiumization, adding a certain amount of sodium salt to the slurry in step S2, and sodiumizing for a period of time;

[0049] Step S4: purification;

[0050] Step S5: organic activation, add a certain amount of organic ammonium salt and activation auxiliary agent, activate the reaction for a certain period of time, the activation auxiliary agent is 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and A mixture of tungstophosphoric acid PW12;

[0051] Step S6: filtering, drying, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com