Method for quickly preparing flavonoid glycoside from oil-tea meal

A technology of camellia oleifera meal and flavonoid glycosides, which is applied in the field of rapid preparation of flavonoid glycosides in camellia oleifera meal, can solve the problems of large amount of solvent, numerous steps, and limited conditions, and achieves strong repeatability of stability, small loss of active ingredients, and easy mastery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for rapidly preparing flavonoid glycosides in camellia oleifera meal, comprising the following steps:

[0036] (1) Use ethanol to extract the total flavonoids of camellia oleifera meal; the volume ratio is 50-95% ethanol, the extraction temperature is 40-70°C, the extraction liquid-solid ratio is (5-15):1 (ml:g), and the extraction times are 1- 4 times, each extraction for 1-3 hours, the extraction is carried out under stirring conditions, the stirring rate is 100 rpm, the extract is concentrated under reduced pressure to recover ethanol, and the crude extract of flavonoids of camellia oleifera meal is obtained;

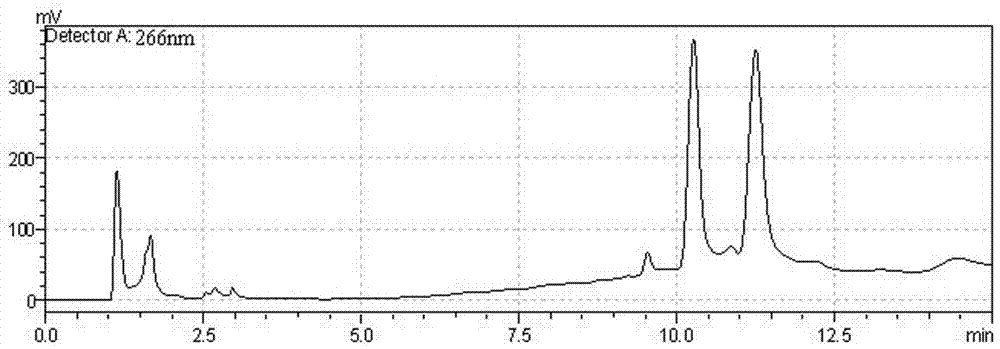

[0037] (2) Purification of macroporous adsorption tree: Add water to the crude extract of camellia oleifera dregs flavonoids obtained in step (1) to prepare a crude extract of flavonoids from camellia oleifera dregs with a concentration of 3-8 mg / mL, using weak polar macroporous adsorption resin model HZ816 , particle size 0.3-1.2, for dynamic adsorpt...

Embodiment 2

[0040] A method for rapidly preparing flavonoid glycosides in camellia oleifera meal, comprising the following steps:

[0041](1) The total flavonoids of camellia oleifera meal was extracted with ethanol; the volume ratio was 95% ethanol, the extraction temperature was 60°C, the extraction liquid-solid ratio was 10:1, the extraction times were 2 times, each extraction was 2 hours, and the extraction was carried out under stirring conditions. The stirring rate is 100 revolutions per minute, the extract is concentrated under reduced pressure to recover ethanol, and a crude extract of flavonoids from camellia oleifera meal is obtained;

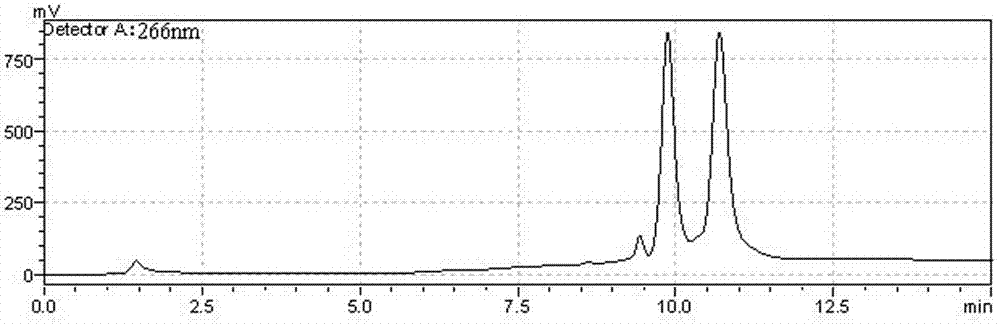

[0042] (2) Purification of macroporous adsorption tree: Add water to the crude extract of flavonoids from camellia oleifera meal obtained in step (1) to prepare a crude extract of flavonoids from camellia oleifera meal with a concentration of 5mg / mL, using macroporous adsorption resin model HZ816, particle size 0.3- 1.2, carry out dynamic adsorpt...

Embodiment 3

[0045] A method for rapidly preparing flavonoid glycosides in camellia oleifera meal, comprising the following steps:

[0046] (1) Ethanol was used to extract the total flavonoids of camellia oleifera meal; the volume ratio was 95% ethanol, the extraction temperature was 60°C, the extraction liquid-solid ratio was 10:1, the extraction times were 2 times, each extraction was 1 hour, and the extraction was carried out under stirring conditions. The stirring rate is 100 revolutions per minute, the extract is concentrated under reduced pressure to recover ethanol, and a crude extract of flavonoids from camellia oleifera meal is obtained;

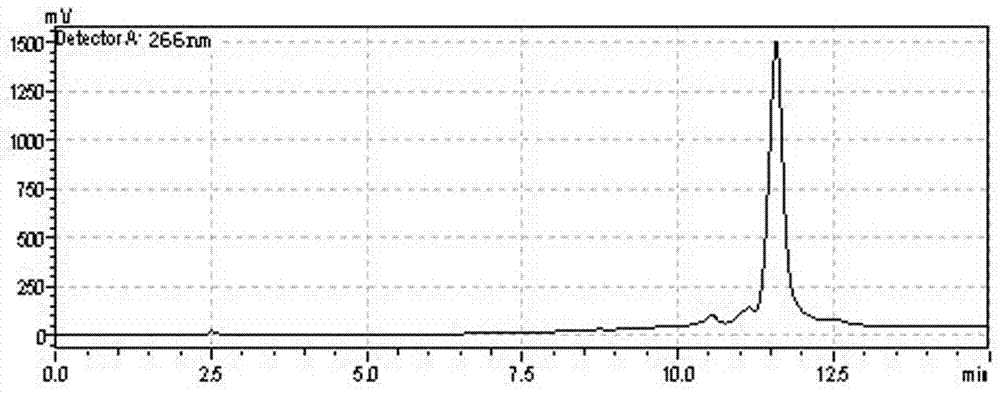

[0047] (2) Purification by macroporous adsorption tree: Add water to the crude extract of flavonoids from camellia oleifera meal obtained in step (1) to prepare a crude extract of flavonoids from camellia oleifera meal with a concentration of 5 mg / mL, and use macroporous adsorption resin for dynamic adsorption enrichment and purification, 25 Dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com