Preparation method of micro low-oxygen titanium hydride powder

A technology of titanium hydride powder and titanium hydride, which is applied in the field of preparation of titanium hydride powder and can solve problems such as the difficulty in preparing high-quality titanium powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Under vacuum conditions, hydrogenate the massive titanium sponge at 450°C and 0.04Mpa high-purity hydrogen pressure for 0.5h to obtain massive brittle titanium hydride.

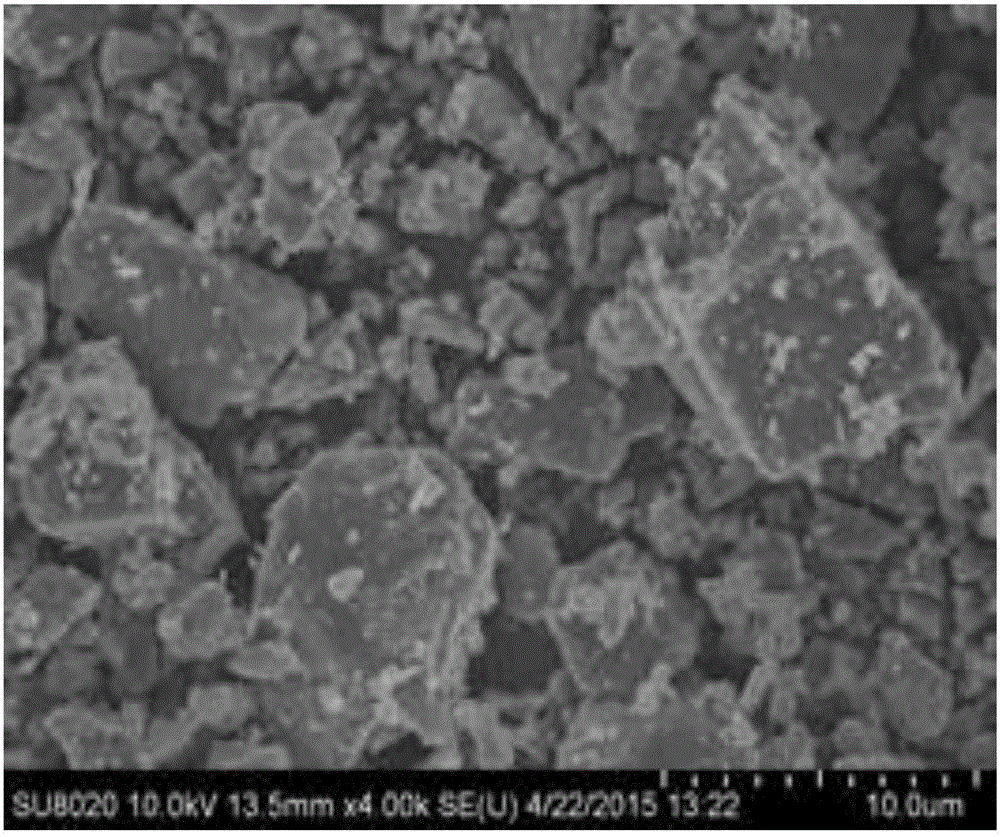

[0020] (2) The titanium hydride powder obtained above is ball-milled at a speed of 300r / min, the ball-to-material ratio is 3:1, and the ball-milling time is 1h. The D 50 It is 7.74 μm, and the oxygen content is 650 ppm.

[0021] (3) SEM test is carried out to the obtained titanium hydride powder, the results are shown in figure 1 .

Embodiment 2

[0023] (1) Hydrogenate the blocky titanium sponge at 450°C and 0.04Mpa high-purity hydrogen pressure for 0.5h to obtain blocky brittle titanium hydride

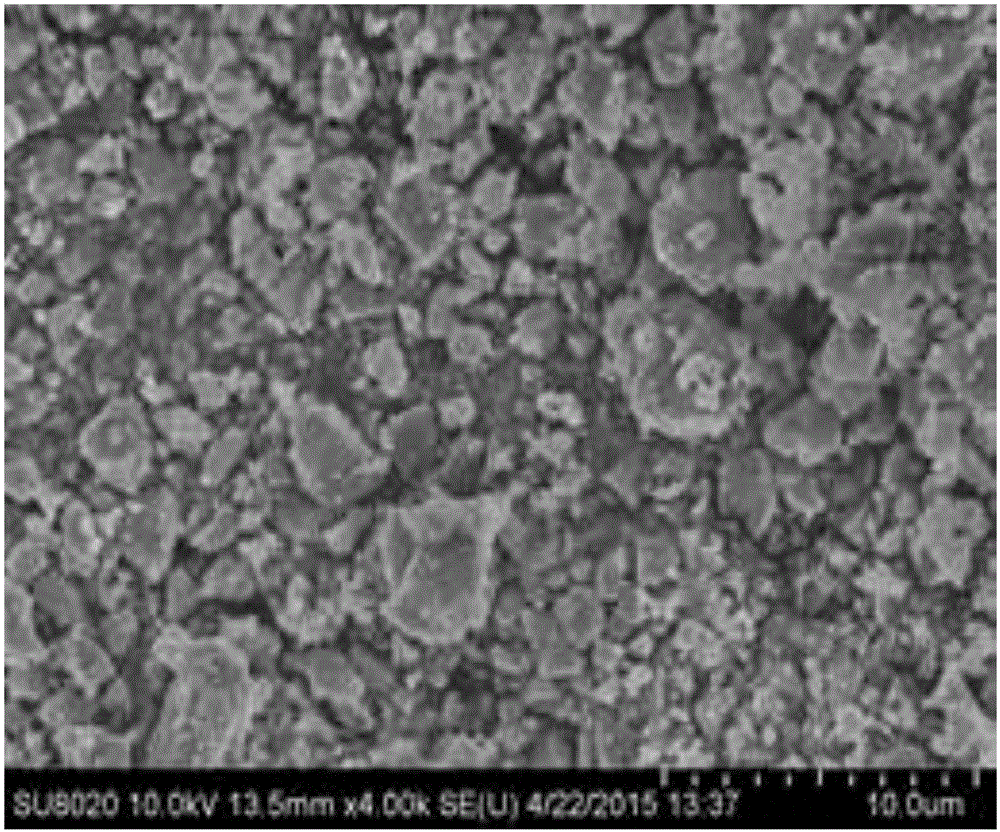

[0024] (2) The titanium hydride powder obtained above is ball-milled at a speed of 300r / min, the ball-to-material ratio is 5:1, and the ball-milling time is 1h. The D 50 is 5.93 μm, and the oxygen content is 750 ppm.

[0025] (3) SEM test is carried out to the obtained titanium hydride powder, the results are shown in figure 2 .

Embodiment 3

[0027] (1) Hydrogenate the blocky titanium sponge at 500°C and 0.04Mpa high-purity hydrogen pressure for 0.5h to obtain blocky brittle titanium hydride

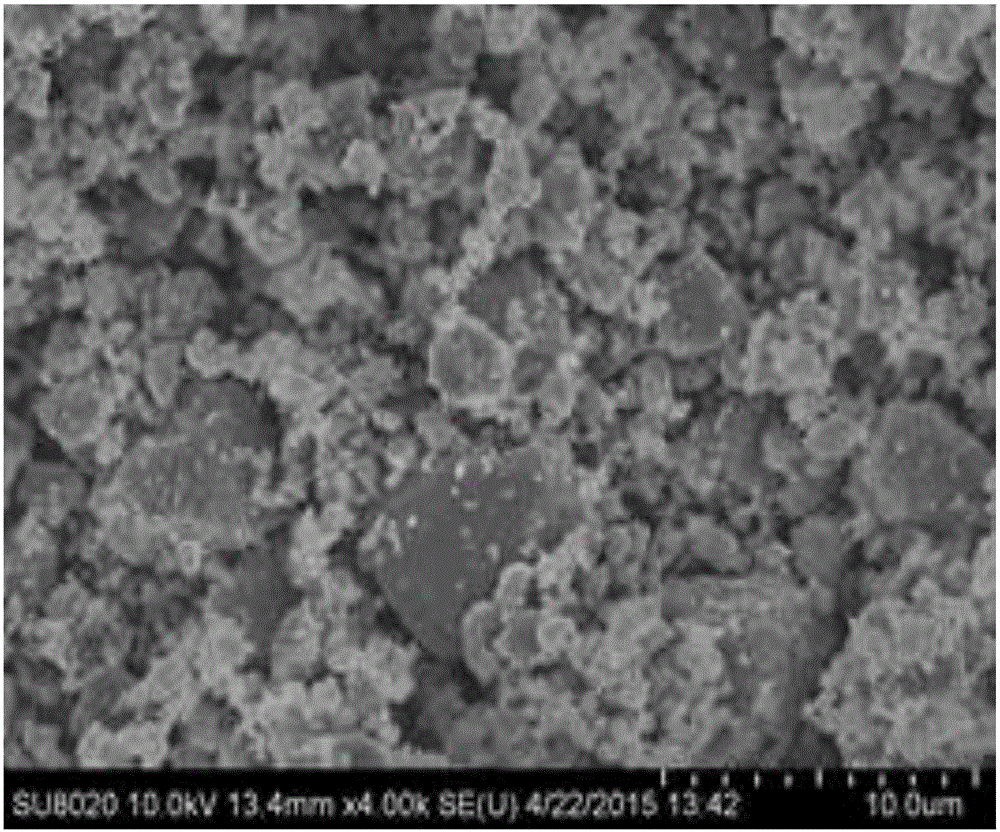

[0028] (2) The titanium hydride powder obtained above is ball-milled at a speed of 300r / min, the ball-to-material ratio is 7:1, and the ball-milling time is 1h. The D 50 is 5.84 μm, and the oxygen content is 700 ppm.

[0029] (3) SEM test is carried out to the obtained titanium hydride powder, the results are shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com