Method for rolling steel plate with heavy and medium plate mill

A technology for rolling steel plates and rolling mills, which is applied in the field of rolling steel plates by medium and heavy plate rolling mills. It can solve the problems of the difference in vertical and horizontal properties of steel plates, and achieve the effect of reducing the difference in vertical and horizontal properties and ensuring the economical efficiency of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] 1. Billet design: the material is common plate Q235B, the rolling thickness and width are 5×3100mm, and the billet with a specification of 115×1450×3200mm is selected. According to the principle of constant volume, the rolling specification is calculated to be 5×3100×34425mm ;

[0026] 2. Heating in a continuous heating furnace, the time in the furnace is 190min, the soaking time is 28min, and the soaking temperature is 1230°C;

[0027] 3. Replace the new work rolls more than 60 minutes before the billet is released from the furnace. After the roll change, 35 pieces, 530 tons of steel plates with a thickness of 30-6mm and a width of 2800-3500mm are continuously rolled, arranged from thick to thin, and the thickness of the last 8 steel plates The order is 10mm, 8mm, 7mm, 6mm, two steel plates for each thickness specification.

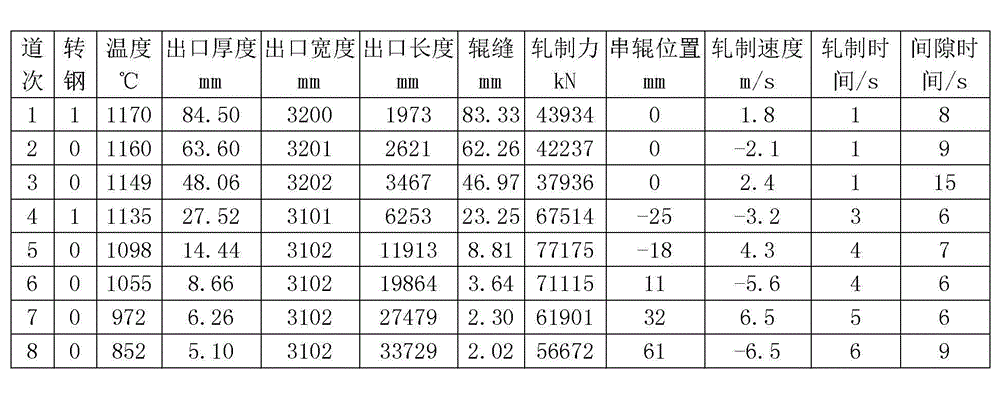

[0028] 4. The main parameters of the rolling mill are set as follows: biting speed 2m / s, maximum rolling speed 5m / s, stand acceleration 2 m / s 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com