A hot-rolled coil of high-silicon and low-manganese pipeline steel and its production method

A production method and technology for pipeline steel, applied in the field of hot-rolled coil for pipeline steel, can solve the problems of high alloy design cost and increase production cost, and achieve the effect of satisfying market demand, small difference in tensile properties, and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

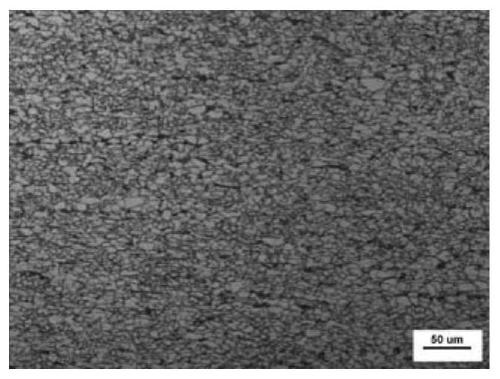

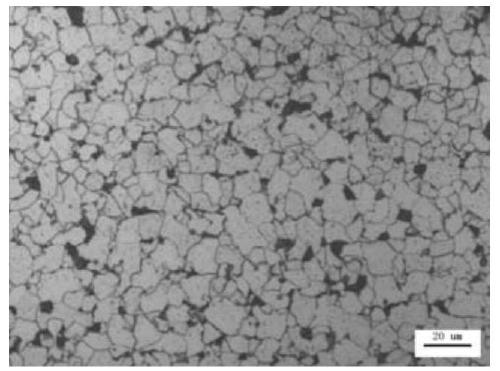

Image

Examples

Embodiment Construction

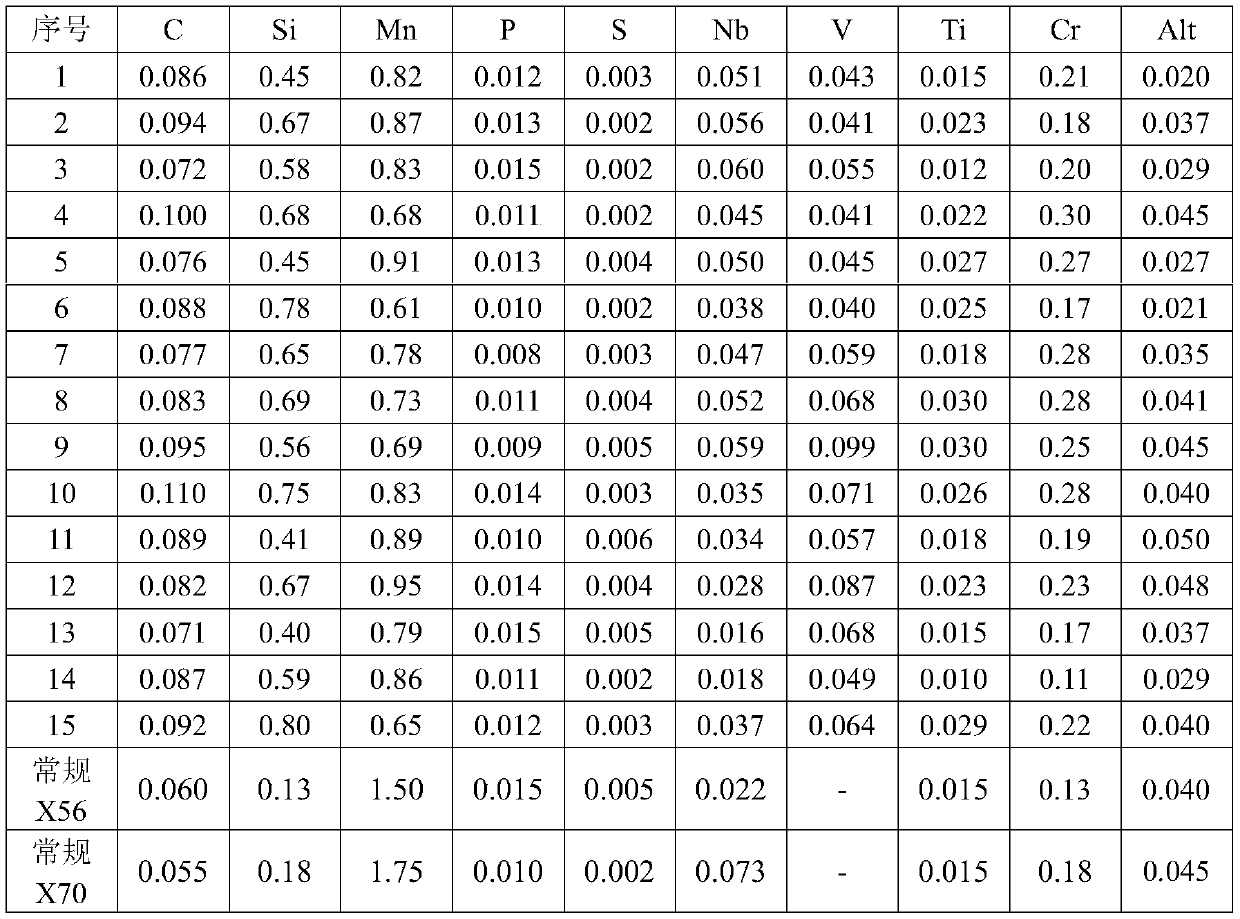

[0032] Below by embodiment the present invention will be further described.

[0033] In the embodiment of the present invention, according to the component ratio of the technical solution, pretreatment of molten iron - converter smelting - LF refining outside the furnace - continuous casting - slab heating - controlled rolling - controlled cooling - coiling,

[0034] During the continuous casting process, the casting speed of the continuous casting slab is controlled at 1.0-2.0m / min, and the thickness of the slab is 135-200mm;

[0035] During the refining process outside the LF furnace, the wire feeding Ca treatment is carried out, and the feeding amount is ≥600m, so as to ensure that the inclusions in the finished product are not greater than 2.0 grades;

[0036]The billet adopts the cold charging process, the billet heating temperature is controlled at 1100-1250°C, the holding time in the furnace is more than 150 minutes, and the billet heating temperature is 1100-1250°C.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com