Martensite precipitation hardening stainless steel for structural member and manufacturing method thereof

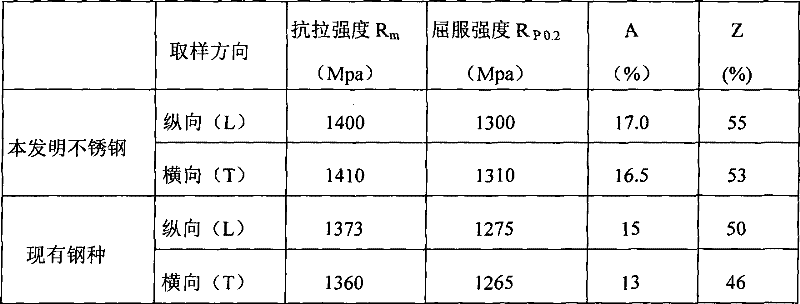

A technology of precipitation hardening and manufacturing method, applied in the field of stainless steel materials and martensitic stainless steel, can solve the problems of sensitivity of heating temperature and holding time, increase the cost of raw materials, and expand the austenite phase region, so as to reduce the vertical and horizontal performance differences, Reasonable chemical composition ratio and the effect of improving transverse plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] According to the chemical composition shown in Table 3, the electric furnace + external refining and smelting, add Al ingot or Ti-Te alloy to the pre-reduced slag material and the reduced slag material, control the end point C at 0.02wt% after oxygen blowing, and discharge it in the AOD furnace Nb-Te alloy is added before steel, Φ510mm electrode is poured, and Φ610mm consumable ingot is remelted after consumable consumption. The smelted steel ingots are furnace-annealed, the annealing temperature is 820-860℃, the holding time is ≥10h, and the furnace is cooled to 500℃ and air-cooled. The annealed steel ingot is heated in a heating furnace, preheated at 500°C for 2.5h, and then heated to 800°C at 50°C / h for 2h, and then heated to 1200°C at 80°C / h for 3.5±0.5h. Then forging is carried out, the forging temperature is 1150°C, and the finishing temperature is 990°C. After forging, air cooling is then annealed at 650℃, holding time ≥48h, and then cooled to 550℃ at 20℃ / h.

Embodiment 2

[0054] The annealed steel ingot was preheated at 520°C for 2.5 hours, and then heated to 820°C at 45°C / h for 2 hours, and then heated to 1190°C at 70°C / h for 3 hours. Then forging is carried out, the forging temperature is 1140℃, the final rolling temperature is 1020℃, after forging, it is air cooled and then annealed at 620-680℃. The rest of the implementation is the same as in Example 1.

Embodiment 3

[0056] The annealed steel ingot was preheated at 550°C for 2.5 hours, then heated to 840°C at 50°C / h for 2 hours, and then heated to 1195°C at 75°C / h for 3.7 hours. Then forging, the forging temperature is 1130°C, the final rolling temperature is 980°C, after forging, it is air cooled and then annealed at 620-680°C. The rest of the implementation is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com